VMC Helps Maker of Rowing Shells in Race to Bring Boats to Market

Outsourcing molds to make a new boat would’ve been expensive and slow, so Hudson Boat Works acquired a Datron MLCube VMC capable of machining large molds in house to get its new product to market three years ahead of schedule.

Share

Saving time can mean saving money, especially in machining. Hudson Boat Works, a manufacturer of racing shells, had this goal in mind when it discovered that outsourcing the moldmaking for its new line of boats would set the project back two to three years. An MLCube VMC from Datron Dynamics (Milford, New Hampshire) has enabled Hudson to make its own molds and move into making production parts in just over a year, ultimately bringing its product to market three years ahead of schedule.

Hudson Boat Works was founded in 1981 by brothers-in-law Jack Coughlan and Hugh Hudson. The London, Ontario-based company is an official boat manufacturer for the Canadian national rowing team, and rowers have won 84 World Rowing Championship and Olympic medals in its boats since 1984.

In 2015, the company set plans to build a line of boats called the Ultimate Super Predator (USP), with all primary components made of carbon fiber. It wanted to bring the boats to market as soon as possible, but the slow turnaround and high costs of outsourcing were problematic. The molds that were needed to make the carbon fiber parts of the rowing scull were projected to take three years to complete.

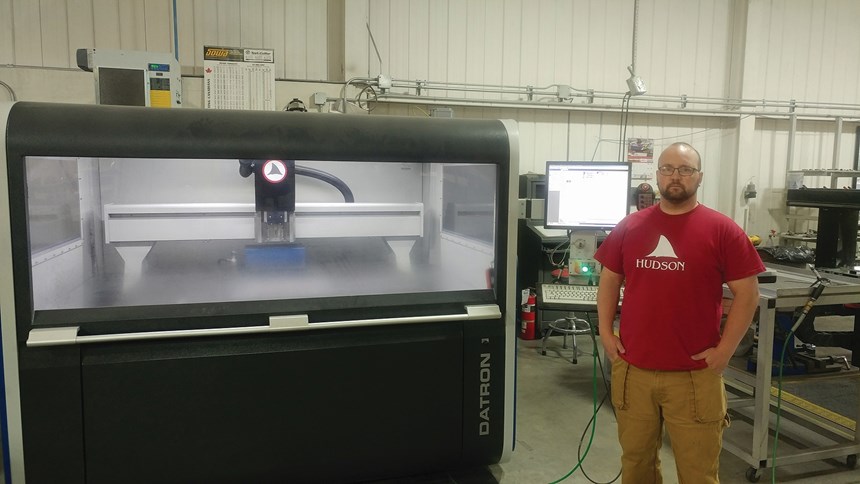

Making the molds in house was not an option with the shop’s existing equipment, says Cam Fisher, a mechanical engineering technologist. “We have a fairly large three-axis CNC router that does all of the trimming for the boat hulls and all of the edge profiling of the boats,” he says, “but it doesn’t have the accuracy needed for moldmaking.”

The company began searching for a new CNC machine, but soon realized it had some challenging requirements. It found that standard CNC routers were not accurate enough for moldmaking, and conventional VMCs had inadequate work areas to machine some of the molds. This problem was compounded by the small, 200-square-foot area on the shop floor that Hudson had allocated for the machine. “We don’t have a lot of room in our shop to put a very large mill,” Mr. Fisher says.

Eventually, Glen Burston, Hudson’s operations manager, came across the Datron VMC. “The MLCube machine just seemed to kind of hit all of the points that we needed,” Mr. Fisher says.

The MLCube has a 60- by 40-inch machining area and a 95- by 90- by 77-inch footprint. It features an automatic toolchanger that holds as many as 45 tools, a spray-mist coolant system and a high-frequency spindle with as much as 60,000 rpm. Feed rate is 866 ipm. It also has linear guides, ballscrews and brushless direct drives, as well as a workholding system with modular plates clamped onto the table using conical centering sleeves, said to provide positioning repeatability and flexibility.

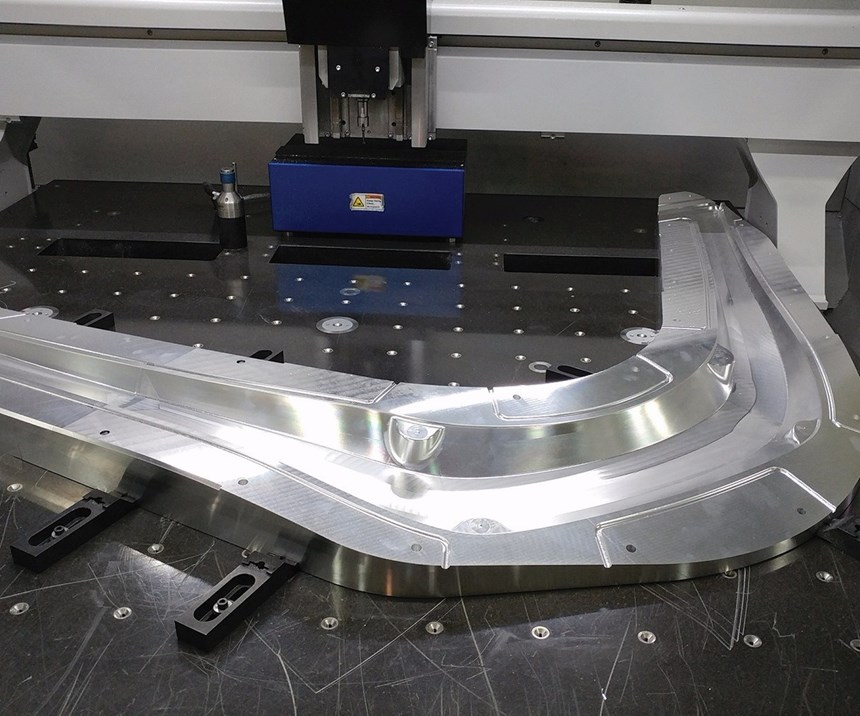

To ensure that the machine’s work area would be large enough for its requirements, Hudson sent its largest mold model to Datron’s technology center for a test fit. This mold, which is curved in a boomerang shape, has a span of 64 inches between the two tips. To accommodate this size, Datron got creative with the part’s placement and relocated the tool magazine on the machine bed. Because this part represented a “worst-case scenario,” Datron says it was confident it had the right solution for Hudson. In just over a year, the shop has milled all the molds for the USP boat and moved to the production phase, using the MLCube to manufacture aluminum parts for the boat rigging.

As it transitions from making molds to making production parts, the company has found the machine’s conical system of workholding positioning to be especially useful. This feature allows the machine to mill conical cavities into its table, resulting in a “boss-in-cavity” system for location repeatability of workholding such as clamps, pallets and vacuum chucks. This, combined with the machine’s large work envelope, means that the machine bed can accommodate multiple fixtures or setups. If operators are in the middle of producing a batch of parts and a rush order comes in, they can either use empty space on the bed or remove a fixture, replacing it when the rush job is complete and picking up where they left off.

Another feature that Mr. Fisher says has helped speed machining of production parts is the ability to use ethanol as a coolant. The rigging parts he is now making will be welded to the boat’s outriggers, and he has been impressed with the quality of the parts as they come off the machine. The ethanol coolant evaporates, so the parts can go straight from the machine to welding with no post work. “They’re just clean and ready to be welded,” he says. “That’s a huge time-saver.”

Hudson also purchased HSMWorks 3D CAM software, which Datron integrated into the MLCube during installation. This has enabled the company to bring its programming in house. “Before, we were outsourcing everything, so even if we did a mold in house, we were still outsourcing all of the programming,” Mr. Fisher says. He says he has found the software easy to use, even though his only previous experience was in 2D programming.

Hudson also plans to use the machine to cut titanium. “Titanium’s not a fun metal to cut,” Mr. Fisher says, “but for one part that I’ve done so far on the Datron, I was running at 200-220 ipm, which is incredibly fast, and I’m still dialing in the feeds and speeds.” He says that Datron application technician Dann Demazure has helped him optimize the program for the titanium part by researching and sending information. “It would have been hard to figure out without a lot of trial and error,” he says, “but the Datron guys always come through.”

Hudson purchased the machine just over a year ago, and Mr. Fisher says it already has saved the company costs up front. “Originally, we were looking at the two- to three-year mark to get everything we needed through outsourcing, and the cost of these very large molds was

astronomical,” he says. “In less than a year, we’re where we wouldn’t have been until about four years from now.”

Related Content

Mazak VMC Provides Versatile Machining of Complex Parts

The VC-Ez 20X vertical machining center features a 25-hp 12,000-rpm CAT-40 spindle with a 30-tool-magazine automatic tool changer.

Read MoreFryer Milling Machine Provides Fast Setup, Simple Programming

The MB-R toolroom bed mill is reportedly capable of single- or multi-part production with a 0.0002" accuracy.

Read MoreIn Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

Read MoreAdditive/Subtractive Hybrid CNC Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)