Video: What Will 5G Mean for Machining?

Faster wireless data transfer could bring new possibilities to machining processes. Modern Machine Shop’s "Data Matters" columnist Matt Danford talks about the manufacturing role for 5G.

Share

Editor’s Note: This was filmed before widespread adoption of social distancing in the U.S.

Matt Danford, Modern Machine Shop senior editor and writer of our “Data Matters” column, spoke with me about 5G and the promise of faster wireless data transfer for manufacturers, particularly machine shops.

Transcript

Peter Zelinski

Pete Zelinski with Modern Machine Shop magazine. I'm here with Matt Danford, senior editor. Matt writes about digital technology for the monthly “Data Matters” column in Modern Machine Shop. Matt, thank you for talking to me.

Matt Danford

My pleasure.

Peter Zelinski

I want to talk about 5G. We all kind of think we're familiar with this term. We see it in the corner of our cell phone screens. 5G has implications for manufacturing, and I want to talk about that. What is 5G?

Matt Danford

5G stands for fifth generation. And basically that that refers to 4G and 3G before it. Just the latest generation of wireless infrastructure, if you will. And so the great promise here is the ability to move more data at a time faster and more reliably.

Peter Zelinski

We don't really appreciate the extent to which limitations on data flow inhibit and define what we're able to do in manufacturing. Would you agree with that?

Matt Danford

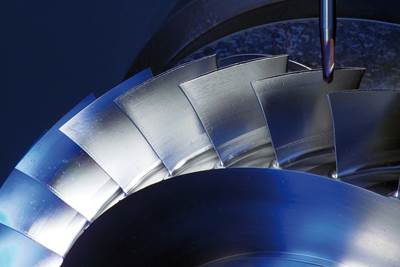

Sure. A lot of times examples are hard to come by because so much of the coverage is sort of from a 50,000-foot view. But I think a lot of the promise of 5G is going to be on the shop-floor level doing things that you wouldn't even think of doing because it's not feasible today. And perhaps the best example I've come across comes out of a research institute in Germany where they were looking at a blisk milling. This is a really complicated process of bladed discs for turbine blades. And these are thin, sculpted blades. They're getting thinner all the time. It's just a really difficult operation. These things take 20-25 hours to mill. There's a lot of value in them by the time they get to that stage. And you don't want to scrap one of these parts. But due to the nature of the parts, chatter is a huge problem. So what they did in Germany, they mounted a sensor directly to the workpiece inside the machine tool, an accelerometer to measure vibration. And thanks to a 5G connection provided by Ericsson, this is the Fraunhofer Research Institute in Germany, they were able to monitor vibration in real time and have the CNC compensate for that. Without 5G this just wouldn't be possible. You wouldn't be able to have that near real time feedback loop between the sensor on the part and the machine to compensate for chatter in this way.

Peter Zelinski

So what would it look like for a capability like that, data capability like that to go more mainstream? What would it look like for manufacturers today to begin to implement capability like that?

Matt Danford

Once it's ready, it may look a lot like implementing a 4G wireless network today. And so if you if you go into any facility with a private 4G network, you know, they'll have a central hub with antennas, strategically placed throughout this facility to spread the wireless coverage.

Peter Zelinski

So when we get to the point where more facilities are using this capability, shops are using this capability, what might that mean?

Matt Danford

Well, I think it means where we would be there, so to speak, in terms of realizing the promise of the so-called industrial Internet of Things or Industry 4.0. And when you talk about a fourth industrial revolution that's characterized by cyber physical systems and greater interconnectedness and this is a key part of the underlying infrastructure that that will make that possible. So I think by the time these networks are installed in manufacturers around the country and around the world, you know, maybe we won't be talking about these buzzwords anymore. This will be the new norm.

Related Content

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

Read MoreGenerating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreRead Next

Talk About 5G Is No Idle Chatter

Near-real-time machining vibration compensation is just one advantage of the latest networking technology.

Read MoreVideo: The Impact of Artificial Intelligence (AI) on Manufacturing and Machining

The machine tool monitoring that many CNC machining facilities are doing today could be a first step toward their use of machine learning. In this conversation, MMS’s “Data Matters” columnist Matt Danford speculates on the coming role of AI for refining machining processes.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)