Video: The Impact of Artificial Intelligence (AI) on Manufacturing and Machining

The machine tool monitoring that many CNC machining facilities are doing today could be a first step toward their use of machine learning. In this conversation, MMS’s “Data Matters” columnist Matt Danford speculates on the coming role of AI for refining machining processes.

Share

Matt Danford, Modern Machine Shop senior editor and writer of our “Data Matters” column, spoke with me about a possible role for artificial intelligence (AI) in machine shops. He sees a path from machine monitoring to machine learning. Today, machining facilities are gathering data from CNCs using machine monitoring systems. A next logical step will be to use machine learning to find opportunities for process improvement within that data. Here is a video of our conversation, with transcript below. Also, be sure to download a collection of articles from Modern Machine Shop and sister publication Additive Manufacturing that explores the intersection of AI and manufacturing as it stands today.

Transcript

Peter Zelinski, Modern Machine Shop

Pete Zelinski here with Modern Machine Shop magazine. I am here with Senior Editor Matt Danford. Matt, thanks for talking to me.

Matt Danford, Modern Machine Shop

My pleasure.

Peter Zelinski

So Matt covers a beat for Modern Machine Shop. Matt writes about digital technology, including technology that in many cases is not quite “there” yet for manufacturing, but is coming. He writes about this in his regular monthly column, “Data Matters.” And what I want to talk to you about today is what you're seeing about the role artificial intelligence might have for machining facilities.

Matt Danford

Well, there's certainly a lot of buzz about that. Most of the readers that we visit, it seems like something that’s far off. For now, they’re really interested more in machine monitoring than machine learning. Whether they realize it or not, though, machine monitoring is really the first step, because the real promise of machine learning, which is a subset of artificial intelligence, is data analytics, at least as far as our readers are concerned. And machine monitoring systems, also shop management and ERP systems, provide the raw data that you need for that analysis. So it’s really sort of a first step, whether they realize it or not, to capabilities that are still yet to come.

Peter Zelinski

Okay, great. So let’s dive into that. Machine monitoring — that’s the step that’s in place today. What do you mean by that specifically?

Matt Danford

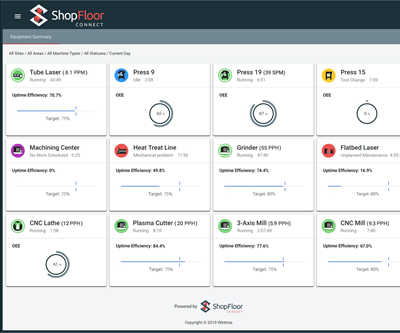

Basically polling data directly from either the control itself or sensors mounted to various components on the machine tool. And, you know, this can be used for things like preventive maintenance. The most common applications we see are people polling CNC data just to see how their machines are performing.

Peter Zelinski

Right. So we walk into shops and we see more and more monitor displays with pie charts or green, red, yellow displays. What does it take to do machine monitoring really well?

Matt Danford

So most of the experts and shops I’ve talked to, there seems to be a real emphasis on patience. Don’t expect everything at once. Just sort of take it slow. Someone I visited recently, they just started out on just basic “what’s-running-when.” And this isn’t just on the manager level. You know, they actually, through integration with the ERP system, had a pacing bar installed at each workstation so that the operators and the people setting up the machines and running machines could tell where they were at. This is how many parts I’m supposed to have produced by now. And so it sort of helps everybody just get a gage on where they’re at and starting with that basic goal. Things like definitions being on the same page. What does it mean to for a machine to be in cycle? Do you count tool changes as part of that time? You really got to get a handle on stuff like that because if you roll it out without these basics, you know, people can get disillusioned and you’re not going to get the results that you’re looking for.

Peter Zelinski

Why is this valuable? We’re still on machine monitoring here. But why is machine monitoring so valuable?

Matt Danford

First, just to get a gage on where you’re at. I’ve heard a lot of experts comment on how they go into the shops and they install these systems and the shops are just shocked that they’re not doing as well as they thought. And so you have to confront that reality. You know, it’s really about truth. I mean, you can’t argue with data from a CNC. There’s no fat fingering that. There’s no delay between when the event happens and when the information is entered into a shop management system. So it’s really about eliminating your own biases and enabling you to take a look at your performance in reality and make decisions from there.

Peter Zelinski

You talked about this path from machine monitoring to machine learning. What’s machine learning? And talk about that path a little bit.

Matt Danford

Machine learning is a subset of artificial intelligence. The definition is really encompassed in the term “learning.” Unlike a traditional computer program that can only do what you program it to do, machine learning algorithms improve with time on their own. The classic example is an image recognition system. As you feed it more images of, say, dogs and cats, it gets better over time with more data you feed it at differentiating between what is a dog and what is a cat. So, you know, applied to our sector of the machine shops that we write about the real promise here again is data analytics. They’ll be able to comb through the raw data provided by machine monitoring systems, shop management systems, et cetera, and find patterns and correlations in that data that would be unobvious, maybe impossible detect by a human, and would certainly require a lot of time and effort to get to the bottom of otherwise.

Peter Zelinski

… anticipating the point where there’s enough data coming out of these machine monitoring systems, where it’s too much data to make use of day to day and potentially masking good intelligence that's there to be found.

Matt Danford

Absolutely. And we don’t know what’s coming yet. We don’t know what capabilities. I've talked to ERP providers that are working with machine learning, but a lot of it is still sort of forward looking. But we do know it’s coming. The best thing to do now is get these systems up and running and, you know, bring your shop management into the 21st century.

Peter Zelinski

Matt, what is your sense of how close this is? How close are we to artificial intelligence in the form of machine learning, being an industrial tool, being something that we use in manufacturing?

Matt Danford

That's really difficult to say. Everything is very forward looking. There’s a lot of hype, justified hype, because it’s going to make a big impact. But yeah, if you think about it one way, you know, the extent that manufacturers use Google, that’s an industrial tool. And Google’s already employing artificial intelligence in its search results and nobody talks about that really. There was no big announcement of “Hey, we’re having artificial-intelligence-driven searches.” And I think it could come about that way. I mean, this stuff is just going to start showing up in your software. And ideally, AI runs in the background. The whole idea is to sort of automate mental tasks. So if you have to pay attention to it and actively manage it, I guess it wouldn’t really be performing or doing what it’s supposed to do. So I think it may be like that. This stuff is just going to start showing up, and we’re just going to be using it without even really realizing that’s what we’re using.

Related Content

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read More4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreFour-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.

Read MoreRead Next

3 Principles for Growing with Machine Monitoring Data

Following a few basic principles can help shops get a return on their machine monitoring systems without losing faith first.

Read MoreMachine Monitoring Provides an Objective Lens

Automatic, real-time shopfloor data collection tempers the bias that blinds manufacturers to the real reasons for downtime.

Read MoreAI Demands Meaningful Metrics

Machine learning can identify patterns and trends faster than any human, but correlations are only as meaningful as the data driving the analysis.

Read More

.jpg;maxWidth=300;quality=90)