Share

A few months ago during Westec, we had a chance to talk to applications engineer Bailey Stump with Marubeni-Citizen Cincom about new capabilities on its flagship Swiss-style lathe, the L20XII ATC (Automatic Tool Changer).

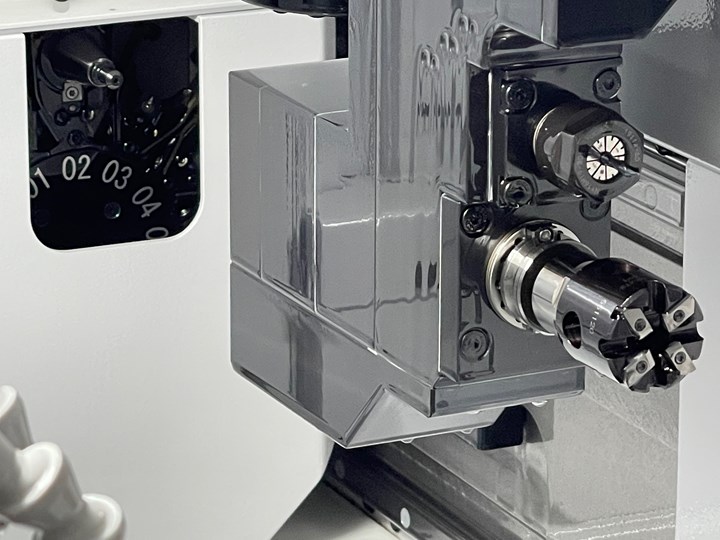

As highlighted in the video above, the ATC tooling with a fully programmable B-axis can be mounted on the gang tool post, enabling a total of 13 B-axis tools (12 ATC tools and one built into the tooling).

The ATC’S tool setting allows for several types of workpieces to be completed in a single setup and used in a wide range of applications — especially parts that require a lot of cross/end face machining. These can include difficult-to-machine components requiring secondary operations like finishing and deburring, components requiring multiple live tools, as well as rough and finish cuts that can be split between multiple tools.

Stump also says that having 13 total tools mounted to the b-axis opens up options for the manufacturing engineering team to get complex or difficult-to-machine parts off the machine complete, minimizing part handling.

Note the tool magazine in the back-left corner. According to Marubeni-Citizen Cincom, this 12-position carousel enters and exits the cutting room along the A5 axis and allows for a tool change in less than under 5 seconds.

Related Content

-

How to Meet Aerospace’s Material Challenges and More at IMTS

Succeeding in aerospace manufacturing requires high-performing processes paired with high-performance machine tools. IMTS can help you find both.

-

Custom Workholding Shaves Days From Medical Part Setup Times

Custom workholding enabled Resolve Surgical Technologies to place all sizes of one trauma part onto a single machine — and cut days from the setup times.

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

.jpg;maxWidth=300;quality=90)