Vector Programming Eases Five-Axis Aerospace Machining

Because the CNCs on this shop’s largest five-axis machining centers accept vector coordinates as program input instead of traditional G codes, critical jobs can be shifted readily from machine to machine.

Share

Desemco can be best described as a five-axis aerospace job shop that can take projects from initial design to final production. This 15-person company in Marietta, Georgia counts on its competitive pricing, top-notch quality and excellent on-time delivery record to win work from a nearby aerospace manufacturer and other aerospace/defense contractors. Desemco’s specialty is complex, high-precision machining of aerospace workpieces in aircraft-grade aluminum, titanium and high-strength alloys such as Inconel. Typical workpieces include longerons, small bulkheads, impellers and window gasket molds.

Five-axis capability is essential to machine many of these parts. Certain geometry, such as complex contours and undercuts, cannot be produced unless the cutting tool or the workpiece can pivot and swivel in simultaneous coordination with the three linear axes of motion. In other cases, lacking access to five sides of the part would necessitate multiple setups that can drive up machine time and jeopardize accuracy.

For this reason, the shop has invested heavily in five-axis machining centers. Among its largest and most capable is a pair of machines from OKK USA Corp. (Glendale Heights, Illinois): A KCV1000 and a VP600. The KCV1000 features an unusually long table for extended X-axis travel (137 inches). Installed in June 2010, this machine has the capacity for the larger, longer workpieces that are the trend in aircraft design. This acquisition was an important strategic marketing move because few job shops have machines of this size. The extra long X axis also enables the shop to set up several smaller jobs on different sections of the table. This flexibility provides significant tactical value for job scheduling and throughput. This machine is a “tool rotation” type. The rotary axes are in the spindle head.

In contrast, the VP600 is a “table rotation” type. The rotary axes consist of a revolving table in a trunnion. Installed in November 2010, this machine also has both strategic and tactical value. In addition to handling the smaller five-axis work that was beginning to crowd the long-table machine, the VP600 can lock its rotary axes and function as a capable three-axis mill.

Unfortunately, acquiring two different configurations of five-axis machines created a hitch in the expected flexibility. Traditional G-code CNC programs postprocessed for the tool-rotation machine could not be used on the new table-rotation machine. To move work readily from one machine to the other, Desemco’s programming staff would have to acquire the appropriate postprocessor for the second machine and apply that to the original tool path data generated in the five-axis programming software from Mastercam (Tolland, Connecticut).

When Desemco turned to the local Mastercam reseller who developed the postprocessor for the first OKK machine, he suggested a different approach. He recognized that the machines’ FANUC CNCs had a software feature that enabled them to process five-axis vector coordinates directly as CNC program input. Although this feature has been available for many years, it hadn’t been given much attention until recently. In Desemco’s situation, it certainly seemed to offer possibilities that merited a closer look.

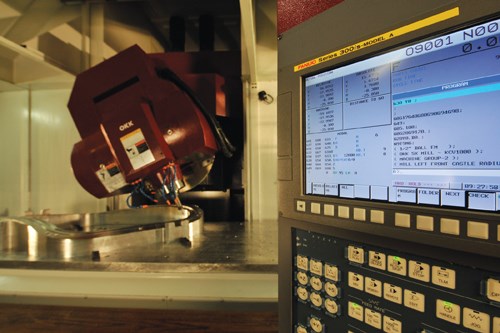

In concept, this “vector programming” option would sidestep two difficulties at once. Because vector coordinates (X-Y-Z, I-J-K) generated by the CAM system define the direction and orientation of tool motion only in relation to part geometry, they are “machine neutral.” That is, the transformations and calculations required to turn these coordinates into machine-specific motion commands haven’t been applied yet. This makes vector programming portable—input for one machine can be carried or transmitted to the other machine and used with little or no modification, even considering that one machine has a FANUC 300iS-Model A CNC and the other has a 310iS-Model A5 CNC.

In addition to bypassing the problem of incompatible G-code programs, vector programming promised to resolve certain postprocessor difficulties. With vector input, the complex math normally performed by the postprocessor is handled in the CNC as the part program is executed. That means the postprocesser has to function only as a simple translator that applies basic data formatting conventions. Moreover, the same postprocessor can now prepare programs for either of the OKK machines. Any machine-specific rotary axis commands, such as reference return, are processed by macros stored in the individual controls.

This sounded like a great idea, but implementing the concept required a team effort that involved the CAM software reseller, the CNC supplier, the local machine tool dealer, and the technical staff at Desemco. Working together, all of the parties were able to make vector programming a successful reality. In fact, everyone was so pleased with the results that they are now committed to a renewed effort to promote this concept more widely in the industry. This “best-kept secret” promises to benefit many other five-axis operations around the country.

Desemco’s sales director, Grant Salmon, considers his shop the biggest beneficiary so far. “When we demoed our portable CNC technology to reps from our largest aerospace customer, they were impressed. They could see that our five-axis capability was more flexible and secure as a result. That gave them greater confidence in our ability to handle complex jobs and get them done on time,” he says. Mr. Salmon also sees a boost in his shop’s business based on this enhanced five-axis capability. “We are planning to get an even larger five-axis machine, but it will probably be a gantry type. That means vector programming capability will be absolutely required for that machine so it fits into our flexible machining strategy.”

Roots

It’s fair to say that a shop culture disposed to advanced technology, especially five-axis machining, is part of Desemco’s roots. Founded in 2008, the company is owned and managed by Mr. Salmon’s wife, Karen, the company president. Her business experience includes operating a successful venture in the custom embroidery industry. Mr. Salmon has a background in the design and production of jet turbine components for high-end scale aircraft sought by serious hobbyists. The couple moved to Georgia from South Africa about five years ago, with intentions to reestablish their respective business operations in the United States.

Originally expected to be a sideline, the production of jet turbine components took off first. The Salmons quickly saw the path to full-sized aerospace work as the most promising direction. Almost from the start, five-axis machining capability was integral to that vision. During this formative stage of the company’s early history, the Salmons happened to meet Dave Watson, a CAD/CAM engineer who had recently retired after a long career at Lockheed’s aircraft assembly plant in Marietta. Mr. Watson’s experience included involvement in computer integration and shopfloor production management—exactly the skills needed by a start-up in a high-tech field. He joined the company in May 2008. Initially, he played a key role in helping Desemco gain certification as an aerospace supplier. More importantly, he guided the shop’s growth as a five-axis job shop, which was backed by the Salmon’s aggressive investment in CAD/CAM and machining technology.

The company now has five five-axis machines in addition to numerous other pieces of CNC equipment. However, Desemco’s precision machining capability exists within a larger technology framework that covers design and engineering expertise, process simulation and optimization, quality assurance and verification, and diverse metalworking processes such as laser cutting, plasma cutting, electrical discharge machining (EDM) and precision toolroom operations. Considering that the shop is only a few years past being a start-up, it is clear that Desemco is on the move. Of course, keeping projects and workpieces on the move through all phases of production is critical.

That’s why the promise of portable CNC programs for its large five-axis machines was a welcome prospect. This would not only avoid a snag in shopfloor flexibility, but also promote the company’s growth strategy. Karen and Grant moved to implement vector programming with their characteristic drive and energy. The technical support they needed from their business partners was readily forthcoming because everyone shared their enthusiasm for the benefits they saw in this project. It turned out to be a shared learning experience.

Jimmy Wakeford, the owner of Barefoot CNC, the authorized regional Mastercam reseller in Morganton, North Carolina, lent his expertise as a CAM software specialist and postprocessor developer. Collaborating with Mr. Watson, he made sure the programming department’s Mastercam five-axis software was set up to generate the appropriate vector coordinates and had the postprocessor capability to deliver machine-ready programs. He also worked closely with Eric Dechant, program manager of machine tool productivity at FANUC FA America’s regional office in Greenville, South Carolina, and Todd Horton, an Atlanta-based sales engineer from Jeffreys Manufacturing Solutions division of Phillips Corp., the machine tool distributor handling the OKK line in the area. Together, they resolved numerous details regarding variable settings for certain machine parameters and motion limits embedded in the logic of the FANUC CNC on each machine. This activity sometimes required input from both the machine tool builder’s factory in Osaka and the CNC manufacturer’s headquarters in Oshino-mura, Yamashita, Japan. Of course, Desemco’s staff of programmers, design engineers and machine operators also contributed to the implementation effort.

By January 2012, the shop had vector programming fully integrated into its operations. For five-axis machine operators like Casey Jefferis, downloading finished CNC programs in the vector format from the file server on the shop’s network is now routine. On the rare occasion that a program needs to be edited on the shop floor, he can make changes to the code, rerun the part and return the altered program to the server. Because the same program is usable at either OKK machine, moving work from one to the other does not require help from the programming department.

Enabling Technology in the CNC

The chief enabling technology for vector programming lies in the CNC, Mr. Dechant says. FANUC has supported vector programming in some format as far back as 2000. As more manufacturers adopt five-axis technology and builders introduce new machine designs with varying axis configurations, interest in vector programming as an option is growing, he explains. Initially, the company’s promotion of this series of controls (FANUC Series 30i/31i/32i-Model A CNCs) placed greater emphasis on the overall depth of advanced features developed by the company to enhance five-axis machining productivity. The vector programming option complemented other advanced CNC functions such as automatic tool center point (TCP) control, tool position control (TPC), nano-smoothing and high speed smooth TCP. All of these functions apply sophisticated software routines to adjust the position and orientation of the cutting tool for smoother, faster machining.

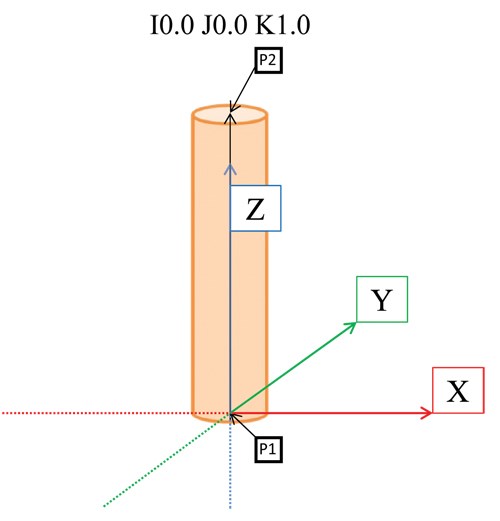

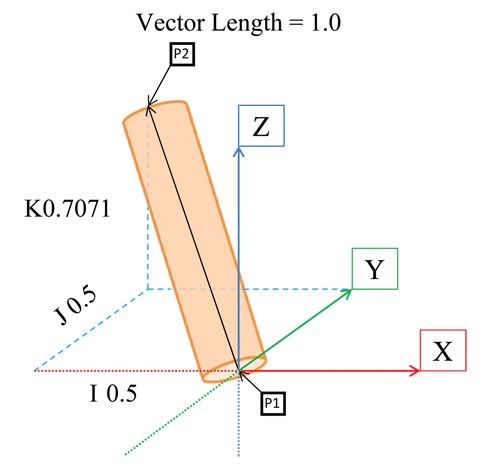

Vector programming goes one step further by subsuming the transformations and calculations normally reserved for the postprocessor when preparing part programs for five-axis machining. Typically, five-axis CAM software generates two sets of corresponding geometric coordinates. The X, Y and Z coordinates represent a series of closely-spaced points in 3D space that approximate the travel of the tool tip across the workpiece surface. The I, J, and K coordinates represent the travel of the opposite end of the tool at a given length. Together, the X, Y, Z and I, J, K coordinates form vectors that define tool position and orientation. See the box on page 73.

One of the roles of the postprocessor in five-axis programming is to relate these vectors to the corresponding pivot points in the actual machine structure. The location of these points varies according to the dimensions and configuration of the machine. The calculations required for these so-called kinematic transformations can be very complex. This is a reason why developing postprocessors for five-axis machines can be a demanding challenge, and why running these programs consumes time and data processing resources in a programming department. Adding to the challenge is the fact that, to some extent, the accuracy of these calculations depends on establishing precise values for variables in the postprocessor routines.

In the past, the job of the postprocessor was to take the data from the CAM system (typically CL Data or a similar format) and turn it into code that was usable for a specific machine. In addition to the tool length, diameter, pivot length, part location and any mechanical error in a specific machine, the postprocessor handled all the calculations required for the linear and rotary axis positions. Programs were “machine specific,” and changes in any of these variables required a trip back to the programming depart for a redo.

With the advanced capability of today’s CNCs, this is no longer the case. Vector programming moves certain key functions of the postprocessor to the CNC. This enables the X-Y-Z and I-J-K coordinates from the CAM system to be entered as CNC program input. Because the input is based on part geometry, not machine geometry, portability is preserved.

It must also be understood that vector programming is effective on the FANUC 300iS-A and 310iS-A5 controls on the OKK machines because it is integrated with related tool control capabilities. “They work together as a package to improve five-axis machining results,” Mr. Dechant says.

For his part, Mr. Watson was especially interested in successful vector programming. His early years as a CAD/CAM engineer at Lockheed (when the Marietta plant operated as a machining facility for the Martin Aircraft Corp.) saw an intense focus on developing portable CNC programs. “In those days, a proposal to use the cutter location data generated by the APT programming language as machine input was being studied by the aerospace industry,” Mr. Watson recalls. At the time, “readiness” was an urgent concern for the Department of Defense. In the event of a military emergency, DoD planners worried that a lack of portable CNC programs would severely limit the ability to shift production of critical weapon components from factory to factory.

The proposal called for executing postprocessor routines to be executed in the machine controller—a concept similar vector programming. “CNC technology was advancing so rapidly during this period that efforts to create the necessary industry standards couldn’t keep up. Portability of CNC programs became an elusive goal,” Mr. Watson says. He’s gratified to see that vector programming has emerged as a viable option with today’s CNC technology. “I’m especially pleased to see a nimble job shop like Desemco helping pave the way for other five-axis shops to follow,” Mr. Watson says.

Mr. Dechant concurs. “Desemco’s example has refocused attention on the value of vector programming. FANUC will be working harder to get the word out as a result,” he says.

Benefits Abound

Mr. Salmon says vector programming has yielded a cascade of benefits of both tactical and strategic value to Desemco. In turn, the shop’s success is having a positive ripple effect among the suppliers involved in the project. He lists some of the most important benefits to his shop:

• A single, relatively simple postprocessor is available to prepare CNC programs for work targeted to either of the five-axis OKK machines with FANUC controls. This same postprocessor is expected to suffice for additional five-axis machines equipped with similar controls that the shop may acquire. Updates to this postprocessor will keep all five-axis programming current with the latest technology.

• Troubleshooting is streamlined. There is no finger-pointing.

• Postprocessing time is greatly reduced. This frees time in the programming department to conduct more thorough verification and optimization before releasing a CNC program to the shop floor. This is significant because Desemco has become an extensive user of Vericut simulation and optimization software from CGTech (Irvine, California), Mr. Salmon says.

• Quality issues have diminished. Because the simpler postprocessor can be tested and debugged thoroughly, consistently better and more predictable machining results can be expected. Likewise, postprocessor functions executed in the CNC do not vary. Once optimal values and settings are entered at the machine, postprocessing results will always be the same. This has provided a slight but significant improvement in machining time, over and above faster cycle times resulting from program optimization, Mr. Salmon reports.

• Mr. Salmon believes that smoother five-axis moves are improving surface finish as a result of vector programming, but he admits that the evidence hasn’t been verified.

• Vector programming is a market differentiator distinguishing Desemco as a technology leader. Customer confidence has grown because jobs awarded to this shop are not dependent on the availability of any one spindle.

• The shop can be more confident about plans to install a larger five-axis gantry mill because delays or difficulties with a postprocessor are unlikely. The flexibility of this machine as a manufacturing resource will be assured.

• Opportunities for growth are more feasible. For example, Desemco has looked at building or acquiring a satellite machining facility closer to a customer’s assembly plant in another state. New machine tools for this facility can be equipped to use vector programming so that the CAD/CAM technology in place at the Marietta location can serve them, too.

• Customers can supply their part programs to Desemco in the vector format. This makes the shop suitable as a back-up or resource to handle overflow work.

Ripple Effect

Participating in Desemco’s implementation of vector programming has been good for others who took part in the team effort. For example, Mr. Wakeford anticipates less pressure on his postprocessor development responsibilities. He says that a postprocessor for a CNC with vector programming represents a fraction of the effort required for traditional G-code programming.

Mr. Horton sees an opportunity to sell more five-axis machines through the distributorship because vector programming lessens concerns about postprocessor availability and prove-

out. Such concerns often hold buyers back, he says.

Mr. Dechant says that implementing vector programming at Desemco demonstrates advanced technology that can be carried over to other current users or potential users of FANUC-equipped five-axis machines. He considers the benefits of vector programming a largely untapped advantage in the marketplace. “Desemco is one of a few early adopters of vector programming and the first user to really exercise the vector programming option across multiple machine platforms. They have been the perfect fit for demonstrating the value of this technology,” he says.

Success with vector programming has also prompted the shop to implement the latest five-axis feature to the OKK machines, High Speed Smooth Tool Center Point (TCP). This feature includes the functionality of tool center point control, tool posture control and other algorithms that smooth tool motion while finessing tool

posture.

A Global Shift?

Mr. Dechant doesn’t think that Desemco will be an isolated case. The concept of using programs in the vector format as CNC input is not proprietary. FANUC is not alone in offering this capability as an option for five-axis users. “However, having a CNC equipped with this advanced technology is just the first step,” he explains. “Having the expertise behind the CNC is crucial to implement it.” Mr. Dechant recommends that all five-axis shops give it a closer look.

Likewise, Mr. Salmon is eager to promote wider use of this technology. “We all benefit from a stronger base of aerospace suppliers in this country. What is especially important to us is that vector programming strengthens our focus on a seamless design-to-production capability,” he says.

Related Content

Generating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

Read MoreThe Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read MoreCan AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

Read MoreTips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)