Upon Further (A3) Review

Using lean manufacturing’s A3 problem-solving process, Genesis Attachments found that magnetic workholding could provide greater benefits than simply getting parts on and off machines faster.

Share

Communication is clear, concise and visual within operations that have a lean-manufacturing mindset. Genesis Attachments, located in Superior, Wisconsin, is a case in point.

Established in 1997, Genesis, a division of IES, International Equipment Solutions, LLC, designs and manufactures excavator attachments for the demolition, scrap-processing and material-handling industries. Its attachments are used in applications ranging from shearing structural building components to the demolition of military tug boats. In fact, its shears were used at the World Trade Center site to aid in the recovery efforts of September 11 and to cut underwater pipe following the Deepwater Horizon oil rig accident.

Genesis began its lean journey seven years ago in an effort to improve manufacturing speed and delivery time consistency. Like many other organizations, Genesis started its lean implementation with visually based practices such as 5S to improve workplace organization and value stream mapping to identify where value is (or isn’t) being added to production processes. It also installed various message boards throughout the facility so critical production information is easily accessible by all.

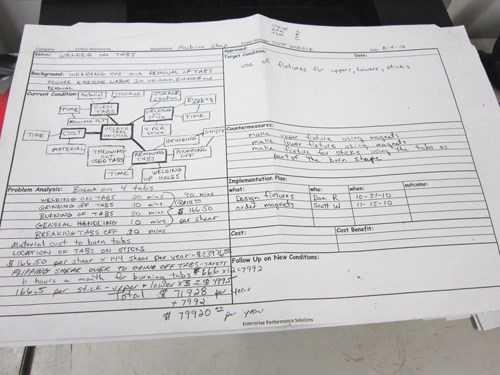

Today, the company uses a similarly crisp and graphical lean-manufacturing approach to identify and remedy root causes of production bottlenecks: the A3 report. An A3 report is so named because it constrains users to document a problem, an analysis, a corrective action and an action plan on one side of an A3-sized sheet of paper (measuring approximately 11 by 17 inches). The beauty of an A3 report is that its brevity forces its authors to drill down to the core of a problem and communicate it (as well as the solution) using clear and concise text and graphics.

Scott Woerle, machine shop supervisor, says A3 reports have greatly improved the production efficiency of shears and other excavator attachments at Genesis. The most recent A3 report he co-authored revealed how a change in the way some parts were secured for machining would have a more dramatic effect on streamlining the overall manufacturing process than originally expected. In fact, switching to a new workholding method saved the company $80,000 per year in manufacturing costs as Mr. Woerle explained during a recent visit.

Magnetic Impact

Each Genesis shear is assembled from a number of components that are plasma-cut from plate steels such as Weldox, Hardox and a custom high-strength steel alloy from SSAB. Some of these plate workpieces are welded together to form thicker “laminates” that require subsequent machining operations. In late 2010, those machining operations were identified as the most significant production bottleneck to be addressed per the company’s continuous improvement efforts.

Mr. Woerle was part of a six-person team including shopfloor personnel that used A3 reporting to determine the root cause of the problem. During the process, the team applied the Toyota Production System’s “Five Why” problem-solving approach in which every recurring problem identified in the process is further analyzed by asking “why.” This question is asked five different times (or as many times as needed) until the root cause of the problem is identified. In this case, the root cause of the machining bottleneck wasn’t the machining itself. Rather, it was the steel tabs that were welded onto components to enable those components to be clamped to machine tables for milling operations.

The A3 report the team generated is shown on the facing page. In the current-condition window, it’s graphically shown that each machined component’s tabs were touched a total of seven times. Below that, the problem-analysis area lists the time and cost of the multiple processes used to create and use the tabs for fixturing. This includes plasma-cutting the tabs, welding the tabs to components, cutting the tabs off the components after machining, grinding the components smooth, general handling and material costs. The team determined that the total annual cost for using hold-down tabs and conventional clamps was an estimated $79,920.

In addition to the significant cost, the clamping method introduced safety issues associated with manually grinding the welds off of components after machining. In addition, welding also introduced stresses into the components that could possibly lead to fractures during shear use.

During the A3 report process, the team identified magnetic chucks as a solution to secure workpieces for machining and eliminate the need for tabs and conventional clamps. The team decided to use Magnos electropermanent magnetic units from Schunk. These chucks take advantage of commonly known magnetic principles to fixture ferromagnetic workpieces for machining. The magnets have north and south poles across which flux, or magnetic energy, flows. When a ferrous workpiece is located between magnetic poles, the flux enters the part and induces polarity in the part (opposite the magnet), causing an attraction between the part and magnet.

The chucks use permanent magnets that are only energized after a quick shot of electricity is delivered by a remote electronic control unit temporarily connected to the magnet. The controller’s cable is then disconnected, and the magnet continues to hold the part until the controller is reconnected and de-energizes the magnet.

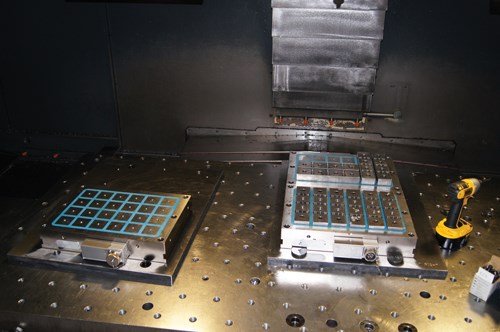

Genesis uses multiple small magnetic chucks to clamp workpieces rather than a single large chuck. Small workpieces might use just one chuck, while larger parts require two or three. In some cases, Genesis uses steel spacer blocks to accommodate different part feature thicknesses to keep workpieces level on the machine’s table. In practice, these spacer blocks serve as magnetic pole extensions through which flux travels to the workpiece.

The magnetic chucks are installed on subplates that originally were attached to a machine’s bed using conventional clamps. Genesis has since added Ball Lock quick-change clamping devices from Jergens to speed and simplify setups. Mr. Woerle says machinist Ted Jerde was instrumental in documenting the layout for magnets for each type of component to be machined. In doing so, he was able to establish locations on the machine table to install the receiver bushings for the quick-change clamping devices.

During setup, a subplate with magnet is positioned on the machine’s table. The quick-change shanks are then inserted through four locating bushings in the subplate and into receiver bushings installed in the table. By turning a setscrew in the head of each shank, locking balls are activated to secure the subplate to the table. Because workpieces are much more likely to rotate on a magnet during machining than be lifted off of it, stand-offs are used to prevent twisting.

When three magnets are needed for a job, two of them are located in fixed positions using the quick-change devices, while the other is manually moved into the proper position and installed with clamps. (When two chucks are used, one is fixed and the other is manually positioned.) All of the shop’s VMCs are equipped to accommodate the quick-change system. This enables jobs to be shifted to a different machine if the original machine is offline due to a malfunction or routine maintenance.

On to the Next Bottleneck

As with any lean operation, once one bottleneck is opened, another is identified and addressed. Using magnetic chucks for machining exposed a bottleneck in the welding department for creating what’s known as “stick bodies,” the largest components of any shear. Therefore, Genesis will soon install a robotic welding cell that uses a similar Schunk Magnos magnetic chuck and Schunk’s Vero-S zero-point, quick-change system to fixture parts. That same fixturing system will be used on one of the company’s horizontal boring mills that performs machining operations on the stick bodies after welding. This will eliminate the need to weld clamping tabs on the stick bodies, providing benefits similar to those realized with the new fixturing method for the laminate components.

Related Content

Custom Workholding Shaves Days From Medical Part Setup Times

Custom workholding enabled Resolve Surgical Technologies to place all sizes of one trauma part onto a single machine — and cut days from the setup times.

Read MoreFixturing Castings Made Simple Through Adhesive Workholding

When a casting proved too malleable for traditional gripping, Thomas/Euclid Industries adopted — and succeeded with — Blue Photon adhesive workholding.

Read MoreNavigating Large-Scale CNC Machining: Suburban Tool’s Niche Strategy to Stay Competitive

Facing increasing competition from lower-cost imports, Suburban Tool made a move toward large-scale, in-house machining. By identifying a niche in large, precision angle plates and tombstones, the company has strengthened its ability to control quality and protect its reputation.

Read MoreChuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More