United Technologies Optimization Tool Added to Vericut

The new feed rate optimization tool is based on machining trials within UTC. The commitment of an established software company will help this OEM bring cost-saving technology to its suppliers.

Share

Machining verification and simulation software developer CGTech says it prefers to develop its software capabilities internally rather than licensing capabilities that were developed outside. It made an exception in the case of Vericut Force, a physics-based machining optimization tool newly made available for the company’s Vericut software. This resource was developed not by another software company, but by manufacturer United Technologies Corporation, or UTC, the OEM owner of Pratt & Whitney, Sikorsky, Otis Elevator and other industrial brands.

Within UTC, streamlining machining processes using the optimization tool, which was formerly called PromptFM, has cut some cycle times by 50 percent. The company manufacturing leaders and researchers involved in developing the utility therefore want to see it used by company suppliers (ultimately saving cost for UTC). To realize this hope, however, the company needed an established software provider willing to back the product and support its users. Allowing CGTech to adopt it was the answer.

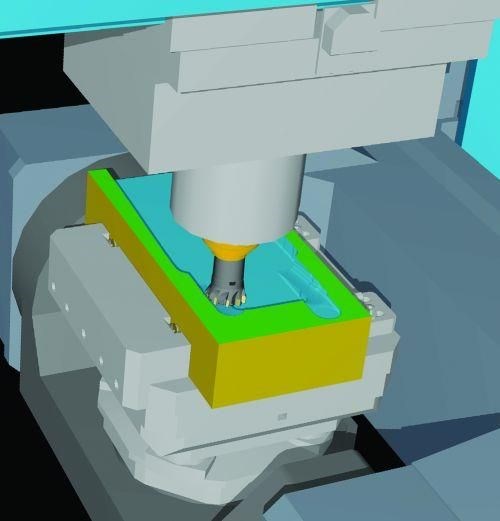

Vericut software from CGTech already has machining feed rate optimization capability. This existing optimization is based on the simulated sweep of the tool’s envelope through the workpiece material. Feed rate changes are calculated from changes in the area of the tool’s material engagement throughout the cut. By contrast, Vericut Force’s optimization draws on modeling of the cut based on metalcutting theory combined with machining experimentation. UTC researchers ran and monitored cutting trials with various tools at various conditions, then interpolated within those results and iteratively refined the software until it produced recommendations that accord with real-world testing.

CGTech says the result is more effective optimization of the cut when cutting conditions are unusual or extreme. Its existing optimization and Vericut Force produce similar results during typical roughing in freer-machining metals, but in finishing hard metals with complex cutter contact conditions, for example, the UTC system offers feed rate recommendations that are nearer to the ideal for that cut.

The initial release of Vericut Force is to UTC companies and their suppliers. The existence of this potential customer base was part of the business case that made licensing the external software product appealing to CGTech. After proving out the new option with these customers, the company says it will extend its availability to the rest of Vericut’s users.

Related Content

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

.jpg;maxWidth=300;quality=90)