Touch Probing with a Feather's Touch

Touch probing technology that requires no stylus deflection allows multisensor measurement systems to probe very small part features.

Share

Autodesk, Inc.

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View MoreMultisensor measurement systems combine the strengths of two or more sensor technologies on a single inspection platform so that all critical features of a complex part can be measured. These systems often include non-contact sensors—video and/or laser—for surface and edge measurements, and touch-trigger probes to reach part features that the non-contact devices can't access, such as cross holes.

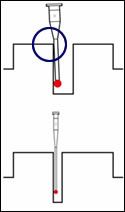

In some cases, the size of a typical touch-trigger probe may prohibit the measurement of very small slots, holes, grooves or bore draft angles, for example. The touch-trigger measurement technique may also prevent such measurements. Because the probe must deflect in order to register a position, it is possible that the probe's shank could contact the part before completing this deflection (this is known as shanking error).

SmartScope multisensor measurement systems from Optical Gaging Products (Rochester, New York) offer touch probing technology that requires no stylus deflection. The technique uses a miniature probe that is in constant micro motion. As the probe's small stylus ball approaches the object to be measured, its micro motion is damped by the part being measured. When the system detects this change in micro motion, it registers the measurement. The probe does not deflect at all, which allows its diameter to be so small and also enables measurement of very flexible of materials in X, Y and Z axes.

To guard against damage when not in use, the probe retracts into a protective housing and deploys only when very fine touch probing routines are required. The probe and housing can be stored in a probe change rack as any other probe could.

Related Content

-

How to Evaluate Measurement Uncertainty

Manufacturing and measurement are closely coupled. An important consideration for the use of measurement results is the associated measurement uncertainty. This article describes common metrology terms and provides an example uncertainty analysis.

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

-

The Link Between CNC Process Control and Powertrain Warranties

Ever since inventing the touch-trigger probe in 1972, Sir David McMurtry and his company Renishaw have been focused on achieving process control over its own manufacturing operations. That journey has had sweeping consequences for manufacturing at large.

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)