Tooling Is the Underappreciated AM Application

One of the significant impacts of industrial 3D printing will be its aid to conventional production.

Share

Takumi USA

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

Read or download the May issue digital edition here.

The automotive industry is among the largest manufacturing sectors, but there is a notion that additive manufacturing isn’t applicable there. Medical and aerospace, two sectors where AM is succeeding, involve relatively low-quantity production. By contrast, automotive production entails the kinds of large part quantities that processes such as machining and molding are very good at delivering. For AM to be relevant to automotive, it would need to print parts at dramatically greater speeds than what is possible today. Or so goes the widely-held view.

Yet that view, which is true as far as it goes, is incomplete.

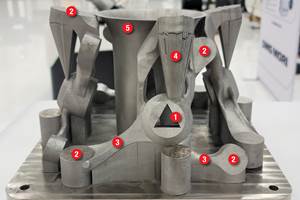

What that view misses is tooling. Tooling—parts for making other parts—is the high-value, low-quantity manufacturing need that is crucial to automotive. According to Harbour Results, a Michigan-based industrial consulting firm with expertise in tooling, car makers spend $50 to 75 million every two to three years on tooling for each model of car, just to freshen and improve the product. For the launch of an entirely new car model, the initial tooling investment is liable to be $700 million. That tooling includes dies, molds, fixtures and so on—and the chance to make some of these tools with less assembly and fewer operations through metal or polymer 3D printing could save car makers considerable cost.

Even today, AM does play a role in making end-use automotive components. Often these are parts for custom or short-run vehicles. So I take nothing away from the promise that printing holds for auto part production. However, given the significance of tooling alone and 3D printing’s promise for tooling, AM could transform automotive manufacturing even if it never made an end-use part. Tooling is the great underappreciated application of industrial 3D printing. Indeed, some manufacturers aware of the value for tooling wonder why 3D printing for end-use part production gets so much attention.

And tooling is the theme you will find running through the May 2017 issue of Additive Manufacturing. Two feature articles—on AES and CPI Aero—are all about tooling. Meanwhile, the article about the Metal X machine touches tooling as well, since the company founder cites tooling as the promising application he sees for this machine. And the item on Diamond Tool and Engineering offers a picture of the design enhancements now possible for molds.

Once you’ve read these, find even more articles we’ve done on 3D printing for industrial tooling in general, and mold tooling in particular.

Tooling deserves this attention. Tooling is the enabler to more efficient production today, even in cases where 3D printing is not the effective choice for directly producing parts. Through AM, manufacturers can make tooling that is less expensive than tools made conventionally, more capable than those conventional tools (because of features such as conformal cooling) and available in far less lead time.

But 3D-printed tooling connects to production in one other important way as well. Namely, tooling can change the culture. In many applications, speed or cost is not the obstacle to using AM; the obstacle is obtaining acceptance of a new part-making process. That acceptance might need to be won internally before it can be sought from the customer. And 3D-printed tooling provides a means of doing this. It provides an entirely internal way for additive to show its effectiveness. Seeing AM in action through tooling, seeing it deliver design and leadtime improvements in this way, can give a manufacturing team the context and confidence it needs to begin applying those same benefits of AM to the production of parts for final use.

Related Content

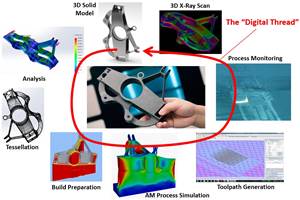

Go Digital: How to Succeed in the Fourth Industrial Revolution With Additive Manufacturing

The digitalization of manufacturing is set to transform production and global supply chains as we know them, and additive manufacturing has been leading the way in many industries.

Read More6 Trends in Additive Manufacturing Technology

IMTS 2024 features a larger Additive Manufacturing Pavilion than ever before, with veteran suppliers alongside startups and newcomers at the front of the West Building. As you browse these exhibitors, as well as booths found elsewhere at the show, keep an eye out for these trends in AM.

Read MoreThe Cool Parts Showcase Seeks Innovative 3D Printed Parts

Do you solve problems with 3D printing? Enter your 3D printed parts in this contest from The Cool Parts Show.

Read MoreDesigning a 3D Printed Part with Machining in Mind

Designing extra stock and mounting features into a 3D printed part can aid in machining processes downstream.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)