Titan Launches Machining Tutorial Website

“Titans of CNC Academy” provides free access to tutorial videos on topics ranging from modeling and programming to vise setup to the philosophy of faster cutting.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

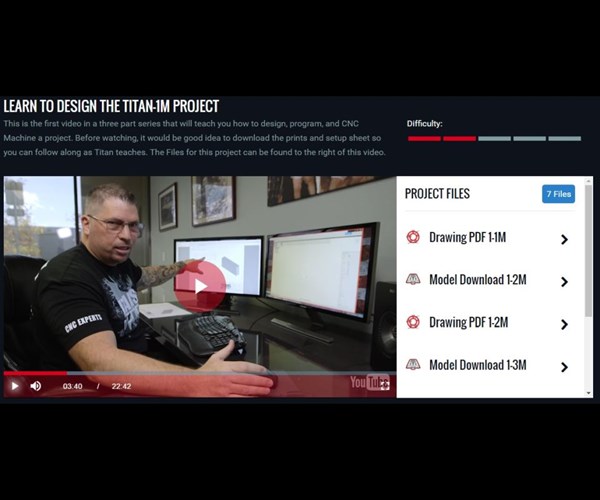

The site’s contents include a three-part video lesson in which Titan Gilroy teaches design, programming and machining using a downloadable project.

Titan Gilroy of the “Titans of CNC” TV Show is building what promises to be a valuable resource for understanding both the basic points and the broader philosophy of CNC machining. His new Titans of CNC Academy website provides free access not just to episodes of the TV show, but also to brief tutorial videos aimed at teaching concepts ranging from the axes of motion on a machine tool to the impact of running at high feed rates. He says he aims for the site to be a resource for community colleges and other educational institutions preparing machining professionals, but I see the site as being just as useful for machine shops themselves that are performing their own formal or informal training of employees.

Certain companies are prominent on the site. Tutorial videos from Autodesk exist alongside the videos from the “Titans of CNC” team, and Haas Automation also gets significant play in the site’s contents. However, Mr. Gilroy’s promotion of the companies supporting his work does not detract from the applicability or the educational quality of the content, and in some cases—such as this discussion of ID clamping using an expansion clamp—it helps to know which company provided the tooling (Mitee Bite).

Access is free, but requires email registration. Thus, you need to register in order for the hyperlink in the preceding paragraph to work. Once you do register, here are some other videos on the site to check out:

- Live Tooling: The Ultimate Lathe Upgrade. A concise and clear description, brought home with video footage, of one of the most basic distinctions everyone new to CNC needs to grasp. Namely: What is milling, what is turning, and how does live tooling bring them together?

- Ain’t Nothing but a G10 Thing. Mr. Gilroy talks about a recurring production part his own machining business runs, a component of a desalinization system made of G10 composite. There is a lot in this little video—the nature of composites, diamond tooling, soft jaws, and even the significance of part cleaning and deburring.

- Learn How to Edge Find. The wobble of an edge finder and what it means is a point best taught by a hands-on machining instructor right at the machine tool, but this well-filmed video provides a very good alternative.

- Learn to Install a Vise. This one made me a little misty. I’ve worked in media about 24 years, so it has been at least that long since I’ve set up a vise. But I can remember when I tapped the vise with a mallet and watched the indicator in just this way.

- Learn Titan’s Fixture Strip Technique. For a simple part being machined in small-volume production quantities, Mr. Gilroy shows how he machines 36 pieces out of two strips of material in a single cycle on a VMC.

- Pushing CNC Machine Speeds to the Limit. Fast feed rates are counter to the habits and culture of many shops. In this video, Mr. Gilroy makes the economic case for cutting at higher rates, while also providing a sense of how he tries to encourage a culture of fast cutting in his shop.

Related Content

Finding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read MoreInside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

Read MoreIn Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

Read MoreDN Solutions Responds to Labor Shortages, Reshoring, the Automotive Industry and More

At its first in-person DIMF since 2019, DN Solutions showcased a range of new technologies, from automation to machine tools to software. President WJ Kim explains how these products are responses to changes within the company and the manufacturing industry as a whole.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More