Thermally Stabilize Spindles With Air

Heat is the number one enemy of machine tools. The machine tool spindle is one of the prime sources for generating heat in a machine.

Share

Heat is the number one enemy of machine tools. The machine tool spindle is one of the prime sources for generating heat in a machine. Before the introduction of integral spindles, most machine tool spindles were driven via belts or gearboxes attached to a remotely mounted drive motor. For the most part, integral motors have replaced these arrangements. Integral spindles are used on turning centers, machining centers, grinders and most other machine tool variations.

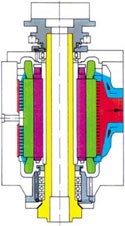

On integral motors, the motor shaft pulls double duty as both the electric motor rotor and the machine's spindle. A cartridge that holds the windings surrounds this shaft. It's a nice clean, compact package that is easily integrated into machine tool design.

However, integrating the electric motor into the spindle creates a heat source that in precision machining applications must be controlled. The cutting tool is in direct contact with the spindle, and as the spindle dimensions change due to thermal growth, the cutting tool's position is affected.

That's why many builders use an active system to stabilize the temperature of the machine spindle. When indirect drive motors were used to run the spindle through a gearbox, the gearbox was directly cooled by oil. Most integral spindles use a cooling jacket around the outside of the stator housing with water or coolant as the cooling medium.

The water jacket that surrounds cylinders in an automotive engine block indirectly removes heat from the combustion chamber. Obviously coolant would not work inside the cylinder.

Likewise, a spindle cooling jacket indirectly removes heat created by the moving rotor and internal winding that has transferred to the stator. The drawback is, of course, that the cooling media cannot contact the inside of the motor, particularly the ends of the windings where a lot of heat exits. In addition, the cooling water has to be pumped through a separate heat exchanger, adding to the cost.

Index Corporation (Shelton, Connecticut) has come up with a different and more efficient spindle cooling system. The company's patented design uses air as the cooling medium.

This system blows cool outside air around the stator and through the motor at the same time. It allows for a very effective method of cooling both the inside and outside of the integral spindle motor.

The effectiveness of this system allows the motor to generate more power, because the motor is able to run cooler. To connect the cool air and the warm air to the motor, Index uses a double tube system, bringing in the cooler air on the outside of the tube and blowing out the warm air through the inner portion of the tube. This system is able to effectively keep the heat away from the machine resulting in reduced dimensional thermal affects.

The cold outside air is typically sucked through a filter from the rear of the machine through the motor. The exhaust typically goes to the top of the machine, blowing the warm air away from it.

A significant benefit of the air cooling system is that it allows Index to also use the integrated spindle motor concept on multispindle machines. Traditionally, a multispindle uses a single drive motor for all spindles. Therefore, spindle speeds could not be independently set.

The compact design of integral spindles allows for their incorporation into multispindle machines, and this gives shops control over each spindle's rotational speed for optimum turning efficiency. However without an active cooling system for these motors, the combined heat would make their application on multispindles impractical.

Read Next

For High Speed And High Productivity, Keep Cool And Stay Calm

Machine tool builders have developed methods to cool off spindles and damp machine vibration for stable machining at higher spindle speeds and faster feed rates.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More