Share

Robotics is becoming more flexible — literally and figuratively. Robots that incorporate new materials into their designs enable new applications for automation, such as handling delicate parts or those varied in size and shape.

Soft robotics are made with less rigid materials than the typical metal and plastic, such as these silicone-based grippers from OnRobot. The flexible materials in these robots make them ideal for parts that are fragile and/or vary in size and shape. Photos provided by OnRobot.

What is Soft Robotics?

Soft robotics is pretty much what it sounds like. These robots are made of softer materials, such as rubber or silicone, instead of more rigid materials like metal or plastic. According to Dr. Andrew Sabelhaus, an assistant professor at Boston University’s College of Engineering, the way soft robots move and interact with other objects is often influenced by nature, taking inspiration from elephant trunks and octopus tentacles.

Soft robotics can bring a number of advantages over hard robotics. Not only can they handle delicate parts and materials better, they’re also more flexible, meaning they can handle parts of varying sizes and shapes. But this comes with a tradeoff. As Sabelhaus points out, the softer the robot or gripper is, the less weight it can handle.

The term can refer to either an entire robot made of soft materials, or just the grippers, which can be added to full industrial or collaborative robots. Kristian Hulgard is general manager, Americas, at OnRobot, a supplier of robotic grippers and end of arm tooling, which offers two models of silicone-based soft grippers. He says that because many soft grippers are actuated with electric servos (including OnRobot’s), there’s a natural synergy with collaborative robots (cobots), making them essentially plug-and-play, as opposed to pneumatic grippers, which need to be hooked up to an air supply.

OnRobot’s grippers fully close around a part, making them easy to program, but more complex applications may require the use of AI in programming.

Get With the Program

Soft robotics can present a challenge in programming, particularly when it comes to applications that handle irregularly shaped parts. Usually, grippers are programmed down to the millimeter to perform the same motion over and over again, but this isn’t possible when the parts or environment aren’t always the same. Artificial intelligence could offer one solution for this challenge — Sabelhaus studies the use of AI in programming soft robots at Boston University’s Soft Robotics Control Lab.

But programming soft robots doesn’t have to be complicated. Hulgard says OnRobot’s soft grippers are programmed to open and close all the way, regardless of the part, and because they’re made of silicone, they don’t damage the part. “It’s a little bit like gripping for dummies,” he notes. This easy programming method also complements cobots, which are designed to be simple to program and deploy.

The weight OnRobot’s soft grippers can handle varies based on the part shape and size (the more the “fingers” can get around the part, the higher the payload capability), so OnRobot has a lab where customers can send parts and the company can test and prove that the grippers can consistently pick up the part.

Food processing and packaging is the most common application for soft robotics, but they are also useful for easy-to-damage materials such as acrylics, or applications where part size and shape may vary, such as in 3D printing.

Applications for Soft Robots

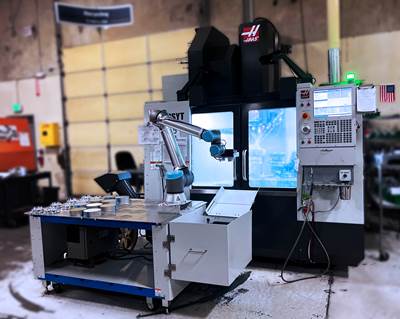

According to Hulgard, the primary application for OnRobot’s soft robotic grippers is food processing and packaging, where items such as fruits and vegetables are both delicate and irregular. However, the company has seen industrial applications for the technology, including one customer that works with plastic parts. “The robot was gripping acrylics coming out of a large CNC mill and they needed very, very delicate gripping,” he explains. “They couldn't leave any type of mark on the part.”

Hulgard could also see potential uses for soft grippers in prototyping applications, perhaps in 3D printing, where part designs can vary within a batch. “Let’s say two differently shaped and sized parts come off the same 3D printer and you need to move them to a box to pack them,” he says. “A soft gripper would be able to grip both parts without making any adjustment to robot movement or to the gripping command itself.”

Sabelhaus also suggests other applications for soft robotics in manufacturing beyond parts handling, including assembly, exoskeletons and remote machine maintenance. “NASA loves this stuff,” he says.

Related Content

3 Ways Artificial Intelligence Will Revolutionize Machine Shops

AI will become a tool to increase productivity in the same way that robotics has.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read More4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

Read MoreInvesting in Automation, Five-Axis to Increase Production Capacity

To meet an increase in demand, this shop invested heavily in automation solutions and five-axis machines to ramp up its production capabilities.

Read MoreRead Next

Handling the Growth of an Adaptable Automation System

Implementing an adaptable automation system helped this shop stay on top of seasonal swings in demand. To effectively grow this system, it had to keep several considerations in mind.

Read MoreOne Next-Step Advancement for Cobots: Specialized Grippers

Grippers and end-effectors developed specifically for collaborative robots represent new advancements in this type of robot technology.

Read MoreCollaborative Robot Gripper Design, Development: Four Trends You Need to Know

Safety standards, third-party certifications, plug-and-play packages and new sensor technology for grippers designed for collaborative robots are making them safer, stronger and easier to use.

Read More

.jpg;maxWidth=300;quality=90)