The Right Gage for Measuring Small Bores

Small bore holes present a unique set of challenges for precision measurement, but small mechanical bore gages can be used for tight tolerances in this application.

Share

ECi Software Solutions, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

Autodesk, Inc.

Featured Content

View More.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Over the years, this column has examined using air gaging and back pressure to measure small bores (under 1 mm/0.040 inch). Air gaging can be an acceptable way of measuring small bores, but it does not provide any form information; it only provides the flow area as related to the diameter. However, because these holes are so small, there may not be another economical solution.

Increase the size, though, and there is a whole family of bore gages available for measuring holes that range from 1 mm to 20 mm; in other words, a whole family of bore gages for these small bores. These precision mechanical bore gages use comparison to determine the size and shape deviations of bores. Unlike fixed plug gages that employ a ground cylinder and sensitive contact to compare a bore to a master, these small, comparative gages basically take the mechanical transfer out of the plug and use it as a standalone probe to measure small bores. Since there is no centralizing plug, the small-bore probe is rocked through the bore being measured to capture the smallest value related to the diameter of the bore — very much in the same manner as the tried-and-true adjustable bore gage.

The big difference — or perhaps the small difference — is that this type of probe bore gage can measure bores a lot smaller than the normal, adjustable bore gage. The adjustable bore gage is just as its name implies: adjustable to cover a large range of parts, but with a very limited measuring range. For example, a small-bore probe with a nominal size of 1 mm will measure a bore from 0.95 to 1.15 mm; a nominal 10 mm probe can measure 9.4 to 10.6 mm; and a nominal 20 mm probe can measure 19.4 to 20.6 mm bores. Though limited in range, these bore probes have repeatability better than 1 μm and will be accurate to 1% of the measuring range.

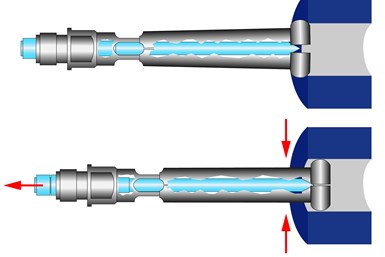

So, what is really happening with these small-bore probes? As noted, they operate very similarly to fixed plug gages. There are two sensitive contacts held with flexures. As the contacts change with bore diameter, they transfer the size via a tapered pin to the indicating device. The indicators can be a dial, digital indicator or comparator, or even a linear variable differential transformer (LVDT) probe and amplifier.

As with any comparative gage, these small probe gages require a setting master. The user of these bore probes will place the master on the bore probe and rock the bore plug in a side-to-side manner, observing the indicator readout and watching for the reversal point, or the smallest value. The user will then set this point to zero or the nominal size. Once set, the gage is taken to the bore to be measured and the same rocking process is used to find the diameter. With today’s digital indicators, this process can be easier since many digital indicators have dynamic memories that can latch upon the minimum value, eliminating the need for the user to remember the reversal point.

These probes can be used in special stands that will orient the small-bore probe to the part and lower it into the bore. When used in this manner, the bore does not have to be rocked, as the probe is square to the bore because it is self-centralizing and will therefore provide the actual diameter deviation.

Like fixed plug gaging, the probes are available in through- and blind-hole configurations and with chromed contacts for normal wear conditions, or a diamond-like coating for extreme wear applications.

Small probe gages are often the only means of precisely measuring bores from 1 to 5 mm. In the hands of an experienced user, they can provide the results needed for tight tolerance bore measuring applications.

Related Content

Choosing the Correct Gage Type for Groove Inspection

Grooves play a critical functional role for seal rings and retainer rings, so good gaging practices are a must.

Read MoreBallbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreHow to Calibrate Gages and Certify Calibration Programs

Tips for establishing and maintaining a regular gage calibration program.

Read MoreParts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)