Share

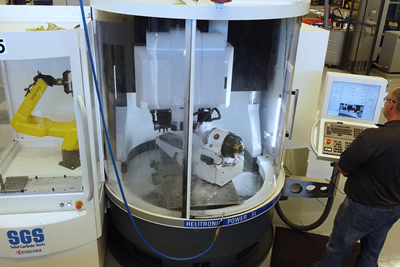

Kinetic Company Facilities Manager Cash Masters and VP/General Manager Jeff Midday look at one of Kinetic’s larger surface grinding machines. Kinetic has 22 grinding machines, which it uses to make hardened wear products, particularly industrial knives for steel and paper mills.

Beyond specializing in certain processes, machine shops also typically specialize in certain volumes. Even if the machining processes are the same, running both small- and large-volume jobs can become too complex for some shops to manage. Making one really high-quality part and making 100,000 high-quality parts require very different thought processes and switching between the two can be a challenge, not to mention figuring out a schedule that can handle both types of jobs at the same time.

The Kinetic Co. Inc. is a manufacturer that specializes in making hardened wear products, particularly industrial knives for the paper and steel industries. Manufacturing this type of product requires several processes, including machining hole patterns and profiles, along with precision surface grinding to create the blade thickness, height and angles.

Kinetic manufactures several product lines that range from long- to short-run production, and the company also takes on contract work. This means Kinetic deals with both high- and low-volume production, with part numbers ranging from one to hundreds of thousands.

“That's really what makes what we do challenging,” says Jeff Midday, VP and general manager. Process expertise and careful planning of production enables Kinetic to guide both types of jobs through machining, grinding, heat treat and other processes simultaneously.

In addition to precision grinding, industrial knives require machining to produce hole patterns and profiles. Kinetic has eight CNC lathes, six CNC mills and one wire EDM to perform these processes.

Perfecting the Process

According to Midday, the first key to balancing low- and high-volume production is process expertise. “Because we're focused on the materials and the processes, we're really able to make everything from one piece all the way through hundreds of thousands of pieces,” he says. Kinetic’s process expertise comes from 75 years of experience in making these parts, including experience in the niche process of rotary surface grinding.

Kinetic has also mastered its machines. Many of the company’s Blanchard and Mattison grinding machines are upwards of 30 years old, and to keep them running at the tolerances required, it has instituted a strict maintenance and rebuild schedule. “It's a foundational piece of this business. It's integrated in our ERP system. It's integrated to our thought process,” Midday says. “Maintenance doesn't wait because we have a hot job. Maintenance gets done. Period. If machines aren't clean, they get cleaned.” Additionally, Kinetic has a multi-million-dollar capital improvement and upgrade program underway.

Knowledge of the machines runs so deep at Kinetic that much of the maintenance is performed in house instead of relying on outside technicians. The company’s maintenance team is capable of scraping, refurbishing, and rebuilding Mattison and Blanchard grinding machines.

Kinetic has a strict maintenance schedule that keeps its Blanchard and Mattison grinding machines (many of which are at least 30 years old) hitting the tight tolerances needed. Maintenance tasks are integrated into the company’s SyteLine ERP, and employees are expected to clean their machines daily.

Staying on Schedule

The second key to managing varying part volumes is production scheduling. Kinetic’s production scheduling team is responsible for looking at reports and organizing jobs so ones with similar setups and materials can run together. This is relatively new for the company, which just reorganized its production scheduling system a few months ago.

Prior to this change, Midday says it was difficult to balance discrete customer orders and internal deliveries to stock products. Because many of the products Kinetic makes are consumables, the company must keep some stocked for customers who expect quick turnarounds. “A lot of product that should have been on the shelf was being made just in time,” he says. Understanding its customers’ needs and expectations for short lead-times and immediate customer service, Kinetic instituted some changes to improve its strategic inventories.

The new system includes two full-time production planners: one responsible for paper and contract work, the other for steel and wood products. “What that allows them to do is focus on knowing not only the work centers, but also the products that go through them so they can commonize the materials, commonize the processes and start to recognize patterns,” Midday explains. The production planners meet four times per week with the plant manager and shop supervisor to review the production plan. This helps with the company’s cadence and provides greater visibility to everyone. “Production planners are also constantly out in the shop talking to the leads, making sure they're getting feedback on issues, and making those adjustments as we need,” he adds.

Kinetic’s production planners organize jobs to keep similar setups and materials together, and machine operators can also choose the order of their jobs to maximize efficiency. Since implementing changes to its production scheduling system several months ago, Midday says the company has improved safety stocks on its high-running, critical spare inventory parts.

When jobs get to machine operators, they also have the freedom to decide how to best run the work. “Our operators have a list of jobs in front of them, and they're not required to go top to bottom,” Midday says. Operators are expected to find the best order based on part geometry and due date.

Hot jobs would often throw a wrench into the system, so the company took steps to reduce expedites. Now when a customer wants to expedite a job, they’re prompted to provide information including the original due date and a requested new due date. “Customers often were saying, ‘I need this fast. I need this fast.’ And we felt as though it was just because they wanted it faster, not because they needed it faster,” Midday explains. “So we put this expedite process in place and it took expedites down by 90%.” He says that this has helped smooth production and enabled the company to more easily accommodate rush jobs when they do occur, while minimizing effects to the rest of the production schedule.

This system has also helped Kinetic with its stock products. It monitors its safety stocks and regularly reviews its raw materials inventory during meetings. According to Midday, “Over the last four months, we have significantly improved the safety stock position on 80% of our high-running and critical spare inventories.”

The Heat Is On

Much of the production plan is contingent on the schedule for Kinetic’s four vacuum furnaces. While many manufacturers send out parts for heat treating, Kinetic brought this process in house in the 1970s. “Everything is long and narrow, so you have warpage through your heat treat cycle,” Masters explains. These parts require specialized fixtures to counteract the warpage, expertise outside heat treaters typically don’t have.

Because Kinetic’s long, thin parts need special fixturing to prevent warpage during heat treat, the company has four vacuum furnaces to perform this process in house. The company works to fill its furnaces before running them, so it builds extra time into its schedules to account for this.

“Heat treating is very expensive, so we have to combine like materials together as much as possible to maximize the furnace loads,” Midday explains. This means the company needs to build extra time into its schedules to account for heat treating. “We essentially have two production plans: we have a production plan to delivery, then there's a production plan inside of that, that looks at cycling like materials to heat treat at the same time so parts don't sit for five to 10 business days waiting for their heat treat cycle.”

The material of every job is identified with a color coding system on the work center load charts generated from the company’s SyteLine ERP system, so everyone can see where each job is. “We rely on our plant manager, production supervisor and heat-treat lead to indicate what loads are next on the heat treat cycle,” Midday says. Heat treat runs six or seven days a week, not due to capacity, but to balance usage.

Even running heat treat this often, Kinetic sees gaps in production where a machine doesn’t have any jobs for several days, then suddenly has a bunch of work. “We try to level load as much as we can with the understanding that inherently our workload is lumpy because of the heat treat cycles,” Midday says. Planners can use the work center load charts to find gaps in production and fill them with upcoming jobs, enabling the company to get ahead. “On one of our 42-inch Blanchards last week, the supervisor came in and he was like, ‘There's no jobs in front of this guy's machine. He's going to run out tonight. What can we pull in?’” he describes. “Ten minutes later, he had five jobs to work on. No one went home. He had two days’ worth of work.”

Kinetic hopes to continue the process it has made with production scheduling. For example, Midday says the company is looking into ways to use ERP data to predict surges in orders for stock parts sooner. “I think we're really at the tip of the iceberg here,” he says.

Related Content

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreHigh RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreRead Next

Keeping Blanchard Grinding Current

What do you do when a large portion of your business depends on machine tools that are more than 30 years old? You roll up your sleeves and perform some of the maintenance of your machines yourself, even if you are the company’s VP, because that maintenance is crucial to the shop’s success.

Read MoreRebuilding Machine Centers: Low Cost, Higher Performance

By sending its grinding machines out for rebuilding, a tooling manufacturer achieved higher speeds at roughly three-fourths the cost of a new machine.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=300;quality=90)