The Hole Business

It's generally acknowledged that making holes is by far the most common metalworking operation. So how does a shop find a way to carve a niche for itself applying such a common process as hole making? This Ohio job shop has managed.

Share

Contrary to the overall malaise in the metalworking industry these days, Magna Machine Company (Cincinnati, Ohio) is doing pretty well. Sure, it has seen overall business levels lower in the last few years, but for this job shop, at least business hasn’t gone over a cliff like many others.

According to company president, Scott Kramer, “a key strategy for Magna’s hanging in during bad times is diversification of the industries it serves coupled with an increasingly better defined machining niche.”

Diversification includes the chemical, paper, plastics, steel, machine tool, automotive and aerospace industries. The company also has a good maintenance and repair business, which is how it got started in 1952. Of the 150 active customers for Magna across these various industry segments, no single one represents more than 10 percent of the shop’s income.

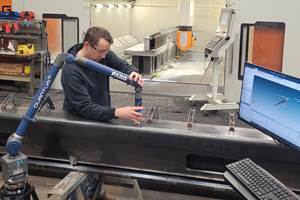

Magna machines big and heavy workpieces. Hole making, boring, milling and turning on a large scale are this shop’s bread and butter.

The shop has invested over the years in horizontal boring mills, which get bigger with each new installation. The shop’s latest machine is a brand new five-axis CNC Union HBM traveling column with 33 feet of X-axis travel and 157 inches of Y-axis travel.

“The niche we’re developing,” says Mr. Kramer, “is large part machining capability. As one moves up in workpiece size, the number of players capable of doing a given job decreases. That’s where we plan to continue to play.”

HBMs Give Flexibility

Magna has built its machining capacity primarily around the horizontal boring mill. It owns four manual machines and 11 CNCs. In 1991 the company purchased and installed its first CNC horizontal boring mill. The rationale for this decision (previously only manual machines were used) was to help migrate the shop’s business from a heavy reliance on repair and maintenance work to machining of new components.

That first CNC machine had a control advantage that was helpful in transitioning the shop’s machinists from manual to CNC. The Heidenhain CNC on that Union boring mill could operate in either manual or CNC mode, a rarity in 1991. “It was a conversational control,” says Mr. Kramer, “It allowed us the flexibility of running in either manual or CNC mode. And programming could be done off-line or on the shopfloor.”

Beyond the application of CNC on HBMs, Magna likes the configuration for other reasons. Making holes with a boring mill equipped with an indexing table allows access to all sides of the workpiece. Moreover, attachments such as 90-degree heads allow five-sided machining. "Our floor mills can make holes or mill on parts that are dimensionally outside the range of the machine tool because the shop floor can actually function as a work table extension,” says Mr. Kramer. “We like the horizontal boring mill configuration for our type of work.”

Coincidental to the acquisition of the first CNC boring mill, Magna won a job machining the rails on a roller coaster for an amusement ride manufacturer based in Sweden. It was one of the shop’s first non-maintenance and repair jobs. Today that business ratio has swung from 90 percent going to repair and maintenance to the current 65 percent of the business coming from machining new parts.

"Adding CNC capability made us competitive for producing more than one-offs,” recalls Mr. Kramer. “It also enabled us to create holes in a new way that wasn’t practical on manual machines—interpolation.”

Picking The Right Machine Tool

Like most job shops, at Magna the job calls the tune. Once capability is in place, correctly matching what’s appropriate for a specific application is where a shop can grow or shrink its margins on a given job. Hole making is obviously one of the more important operations because of its volume.

Because of its niche in large workpieces, the first consideration that Magna’s estimators look at on a job is its size and weight. The initial assignment of a workpiece goes to the machine tool that can handle it.

One example of this decision-making process was a large gear for the steel industry. Finishing the 48-inch deep by 24-inch diameter bore was obviously a job for the shop’s 130-inch diameter VTL. However, the blank weighed 80,000 pounds—too heavy for the 50,000 pound capacity of the VTL.

"We switched the job to one of our HBMs and secured the part on the work table,” recalls Mr. Kramer. “It had sufficient capacity for the weight. The table is rotary, and with the accuracy of the boring mill, we were able to do in-line boring. We fed 30 inches in on one side, indexed the table and fed 30 inches in on the other. We got the job done.”

Picking The Right Process

Like its arsenal of machine tool capacity, Magna has several tooling and technique options to drill, bore, mill or turn the varied holes that come across the shop floor. Like matching a machine tool to a job, the hole-making processes selection is equally critical to delivering a job to the customer’s spec and doing that job as efficiently as possible.

The key parameters that Magna evaluates when selecting the tool and technique for hole making include the following.

- the number of holes

- job lot size

- the size of the holes

- workpiece material

- dimensional accuracy

- surface finish

"For drilling ten holes that are up to a 7/8-inch diameter, we’re just going to use regular off-the-shelf jobber drills,” says Mr. Kramer. "When it comes to a multitude of holes, hundreds of holes to thousands of holes, from 1/8-inch diameter to ¾-inch then we’re going to look at using carbide drills (Mitsubishi MZS) with through-the-tool-coolant. The extra cost of the carbide is justified by the increase in tool life. For the ten-hole jobs, HSS jobber drills are generally more economic.” In short runs, from 20 to 30 holes and ranging from 1.25 inches to 4 inches, Magna uses a spade drill.

For larger hole sizes and for higher quantities, different types of drills come into play at Magna. “When we get into holes from 7/8 inch to 4 inches, and it’s a large number of holes for tube sheets, heat exchangers or similar parts, we use indexable insert drills (OTM Hole shot drill),” says Mr. Kramer. “For the cost and performance in the types of materials, along with the tool life, those drills are very successful for us. The ability to select different grades and coating to match up with the application is another reason indexable inserts work well for us in this hole size range.”

The cutting data for all of the drills in the shop are available to the job estimators at Magna. They know how long it should take to drill a specific hole, and those data are applied to the quotation. These cut data also serve as a benchmark to evaluate new tools against old for improving the hole-making process.

For boring operations, Magna uses a system from KPT Kaiser. It gives the company a boring range of ½ inch to 36 inches in diameter using a modular building block system for making different boring tool configurations. Standardizing on one tooling system is more efficient for the shop, as tools tend to migrate from machine to machine and operator to operator.

These boring bars can be set to produce a 1 ½-inch depth of cut on a given diameter for rough boring. This heavy cut is done using a twin-tip boring tool. Magna sets the lead tip of the boring bar to a depth of ¾-inch. The following tip, set to trail the lead tip by 0.020 inch, is set at a depth of cut ¾ inch deeper than the lead. Each tip is cutting only a ¾-inch depth, but the accumulative action of the two cutters produces a 1 ½-inch metal removal rate on the workpiece diameter.

Finishing large bores is where the total system of machine tool, fixturing, cutter and coolant come into play. Magna generally tries to take a single roughing cut and a second semi-roughing cut on a bore when the casting or weldment allows it. “Most guides from the cutting tool makers suggest leaving a 1/16-inch stock amount on the bore for finish,” says Mr. Kramer. “With that benchmark, we work back to determine if a single rough pass followed by a semi-rough and then finish will get us to size.”

For multiple part jobs, the machinist will set up a roughing head, semi-roughing head and finish head off-line and have these tools ready when production begins. Accurate cutting tools and accurate machine tools are a must for off-line tool setting. “You want to do a minimum of tweaking on the machine,” Mr. Kramer says.

Hole tolerance is the first criteria that Magna considers when choosing between using a boring bar or interpolation. Hole depth is a second consideration, and that determines whether the interpolation is circular or helical. “We may interpolate holes from ¾-inch diameter to 30 inches if the tolerance can live with 0.002 to 0.005 inch on the diameter,” Mr. Kramer says. “If the tolerance is tighter, we’ll select boring for at least the finish cut.”

As for hole depths, 6 inches is generally the cutoff point for boring versus interpolation. Hole depths of 6 inches or more are bored. For hole depths shallower than 6 inches, interpolation is applied, at least for roughing.

"When the tool really has to reach out,” says Mr. Kramer, “we process the part on one of our W-axis equipped HBMs. The W axis extends from the face of the main bearing up to 36 inches in length to allow the spindle nose to be positioned closer to the workpiece. A spindle inside the quill does the feed. This keeps the setup much more rigid.

"What’s nice about having a variety of processing capabilities,” continues Mr. Kramer, “is they give us choices as to how to best make holes. We can drill, bore, interpolate or do combinations of any of these operations. Flexibility within its niche is key to a job shop’s survival.”

Related Content

Inside a CNC-Machined Gothic Monastery in Wyoming

An inside look into the Carmelite Monks of Wyoming, who are combining centuries-old Gothic architectural principles with modern CNC machining to build a monastery in the mountains of Wyoming.

Read MoreESOP Solidifies Culture of Continuous Improvement

Astro Machine Works’ ESOP rewards all employees when the shop does well, inspiring many toward continuous improvement as Astro expands its capabilities.

Read MoreSelect Machining Technologies Highlights Multitasking Machines

IMTS 2024: Select Manufacturing Technologies is highlighting large-capacity multitasking machines from Solace, Geminis, Ibarmia and Momentum.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More