The “Headless Bolt” Fixturing Alternative

This fastener enables fast workpiece change-overs compared to conventional bolts and less cutter interference thanks to its compact design.

Share

Autodesk, Inc.

Featured Content

View More

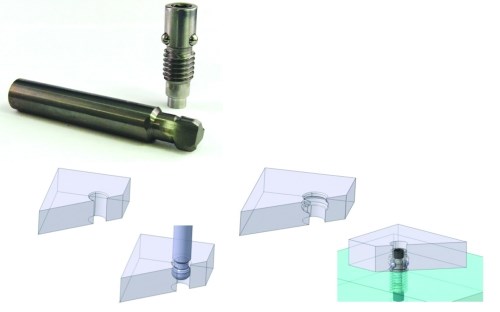

In some cases, conventional bolts are used to secure workpieces to subplates for machining. However, installing and removing these bolts can be time-consuming. Plus, protruding bolt heads often interfere with the cutting tool, preventing it from accessing all workpiece areas that require machining. This can lead to multiple setups and operations to complete parts. As a result, Mitee-Bite has developed its “headless bolt” Loc-Down system so users can quickly attach and remove workpieces from subplates. Not only does this system enable faster workpiece change-overs compared to conventional bolts, but there’s less cutter interference thanks to its compact design.

The Loc-Down system was originally developed to locate and secure aerospace parts for high speed machining operations. However, it is just as effective securing workpieces ranging from thin plate to large blocks. The individual, threaded Loc-Down units are made of heat-treated stainless steel and feature a simple ball-lock mechanism to fix workpieces to a subplate. Users simply drill and tap holes to a specified depth in the subplate and install the units. (Multiple units are often required depending on the application.) Next, a mating through-hole with a special-geometry internal groove is machined in the workpiece. Mitee-Bite provides an end mill to create this groove. Once the workpiece is loaded onto the subplate, users tighten each Loc-Down unit to secure it for machining. Each unit generates 100 pounds of force for every foot-pound of torque.

The Loc-Down system offers the flexibility to fixture a variety of parts and is well-suited for both production and job-shop environments. It also can be combined with the company’s locating pins and liners to create an affordable quick-change system for fixtures used on tombstones and pallet changers.

Related Content

-

Navigating Large-Scale CNC Machining: Suburban Tool’s Niche Strategy to Stay Competitive

Facing increasing competition from lower-cost imports, Suburban Tool made a move toward large-scale, in-house machining. By identifying a niche in large, precision angle plates and tombstones, the company has strengthened its ability to control quality and protect its reputation.

-

Parts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

-

Using Jaws as Grippers Enables Flexible, Low-Cost Automation

VersaBuilt’s automation systems significantly boosted Innovative Fabrication’s revenue. In return, the shop has helped VersaBuilt optimize its products.