Share

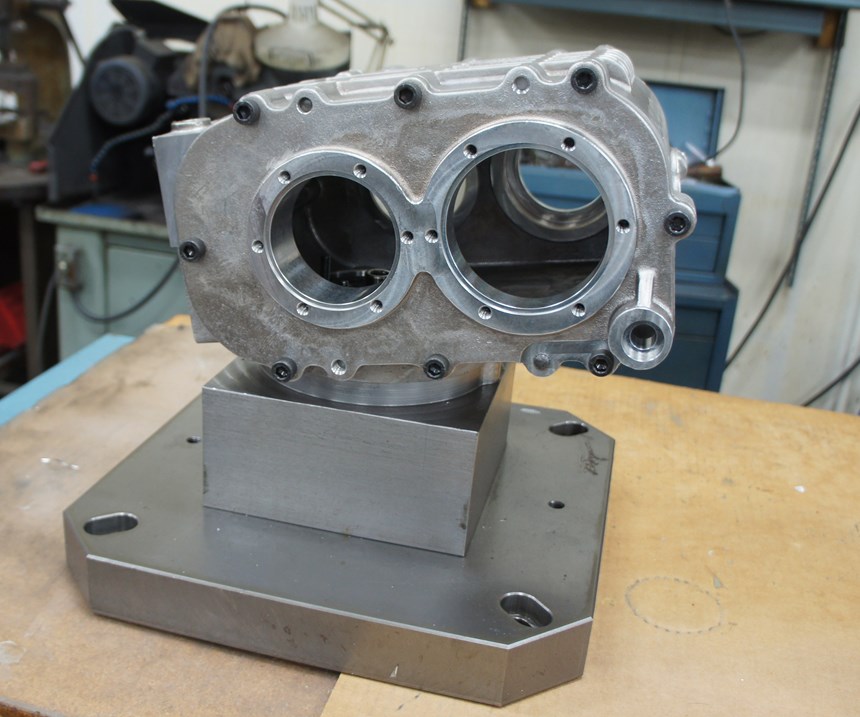

Some machine shops take on work that does not necessarily jibe with their capabilities. That is not the case for Contour Precision Milling & Machining. Instead, this Northeast Ohio shop has chosen a particularly specific niche: low-volume, repeat jobs involving non-round, non-square milled components, particularly castings and forgings. Although this oddly shaped work requires substantial planning and problem solving to develop an effective machining strategy, the shop’s extensive engineering capacity and expertise in designing and building custom fixtures enable it to excel milling these types of challenging parts on equipment including pallet-fed horizontal machining centers and five-axis machines.

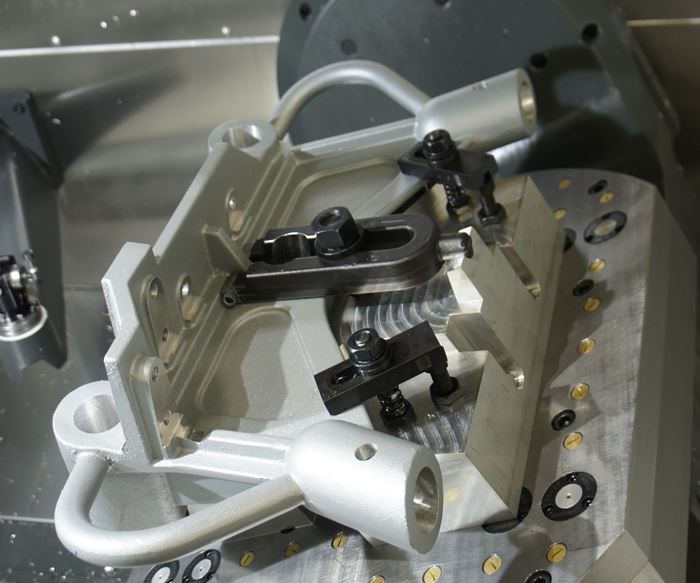

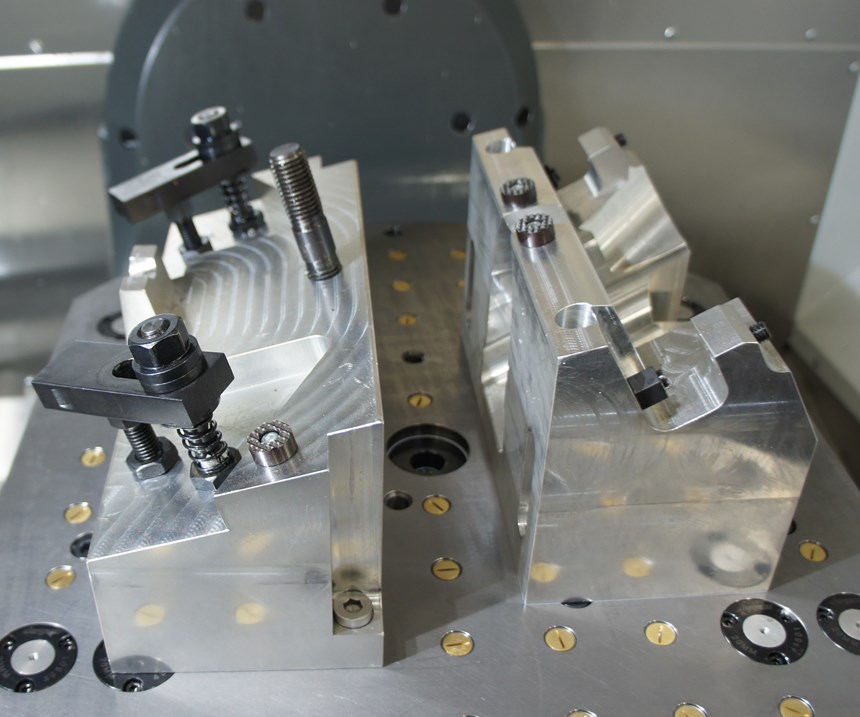

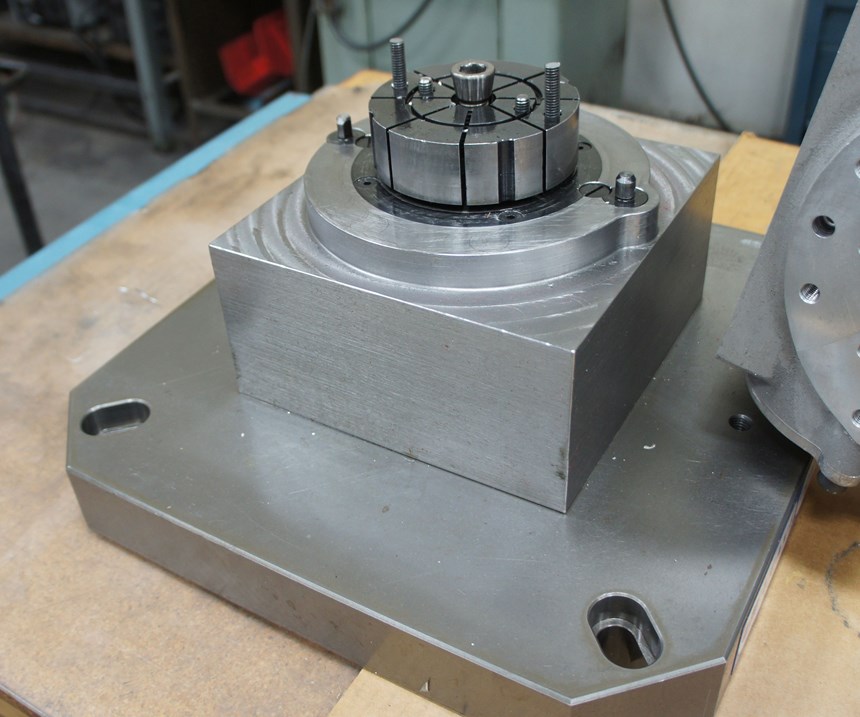

Designing and building its own workholding devices is one of the most important ways Contour Precision helps customers get products to market fast. These tasks fall largely to people such as plant manager Brian Whitt, who started as the shop’s first apprentice more than 20 years ago, and senior manufacturing engineer Mike Kerecz, a nine-year shop veteran. The fixtures they make for castings, forgings and other components with complex geometries are all different, but many of the same principles and strategies apply. Here are a few examples:

Start fresh. Engineering and design assistance is a key value-add for Contour Precision. Ideally, the shop can get involved early enough to choose the starting point for machining, which typically becomes the reference datum against which all critical features are measured. “We just quoted a job that called for holding a rather large machining feature true to a really tiny surface, and that’s not a good way of designing things,” Mr. Whitt says. “We’ll try to work with the customer on the GD&T (geometric dimensioning and tolerancing) for that one.” Given variations in the casting or forging process, the starting point should also have enough stock for initial machining to ensure an even, consistent surface from part to part.

Make time for troubleshooting. For many jobs, the shop does not get a chance to provide design assistance. Mr. Whitt and Mr. Kerecz say it is common for gates, risers and other features of casting and forging molds to be placed with little regard for later machining of the components that emerge from the tooling. All leave extra material behind, and machinists might not know exactly where until the workpiece is in hand. What’s more, results can vary from part to part when foundries remove this material themselves, compounding the natural material inconsistencies of the casting or forging process. On-the-floor experimenting and troubleshooting often are the only ways forward.

Hold on loosely (but don’t let go). Fixtures must strike a balance between gripping parts securely enough for machining and preventing part warpage and “spring-back” upon release. “Usually, holding looser will give you the better-quality part, although you might have to adjust the machining operation to do that,” Mr. Kerecz says. “This enables you to machine the part the same way you inspect it when it’s not in the fixture.”

Make it easy. However complex the workpiece, the fixture needs to be as simple and easy to use as possible for machinists on the shop floor. Otherwise, both time and part quality could be at stake. Beyond attention to ergonomics and the intricacies of loading and unloading during the design phase, this can be facilitated by off-the-shelf technology such as Jergens’ ball-lock mounting system, which is designed for fast, easy and repeatable changeovers. Detailed setup instructions also help ensure consistency from part to part.

Contour Precision & Machining has expertise in more than just fixturing, the shop also has lessons to share in alluring and securing customers.

Related Content

Using Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

Read MoreUsing Jaws as Grippers Enables Flexible, Low-Cost Automation

VersaBuilt’s automation systems significantly boosted Innovative Fabrication’s revenue. In return, the shop has helped VersaBuilt optimize its products.

Read MoreWorkholding Fixtures Save Over 4,500 Hours of Labor Annually

All World Machinery Supply designs each fixture to minimize the number of operations, resulting in reduced handling and idle spindle time.

Read MoreParts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)