Optical Profile Grinder Has Digital Vision

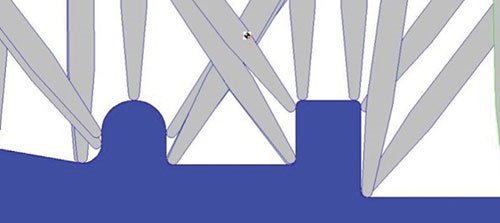

This reciprocating CNC profile grinder uses a digital profile derived from a CAD file to replace the chart or overlay required for optical profile grinders.

Share

Autodesk, Inc.

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

|

|

hydrostatic ways, and linear motors. Modular machine elements that tilt, swing and rotate are available for additional axes of simultaneous control. Workpieces can be loaded and unloaded automatically. Likewise, grinding wheels can be exchanged automatically.

Related Content

-

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

-

Where Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

.png;maxWidth=150)