The Cool Parts Show Reveals 3D Printing Reality and Potential

Now in its second season, the YouTube series from Additive Manufacturing uses cool parts to explore the capabilities of industrial 3D printing.

Share

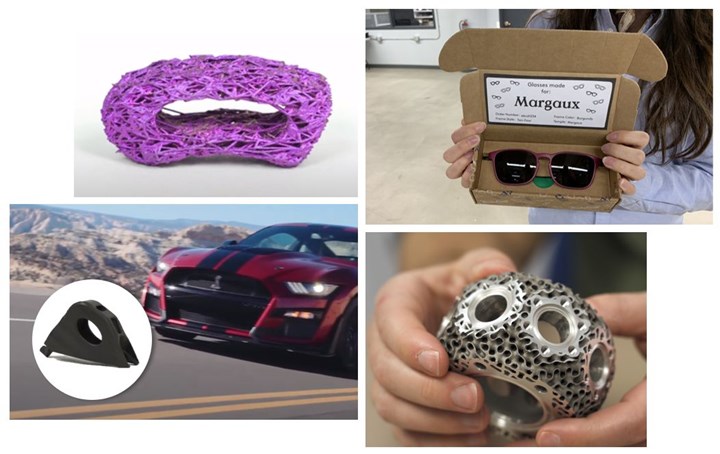

Did you know that there are FDA-registered companies using metal 3D printing to make titanium spine cages? That you can already buy customized products like shoe insoles and glasses frames made through 3D printing? That 3D printed vacuum chambers can support quantum physics research? Or that the Ford Mustang Shelby GT500 contains a 3D printed bracket?

It’s all true!

Over at Additive Manufacturing (a sister publication to Modern Machine Shop), we’ve built an entire YouTube show around applications like these for industrial 3D printing technology. Each episode of our series The Cool Parts Show focuses on a unique, unusual or otherwise remarkable 3D-printed part. Think beyond models or rapid prototyping — every item featured is a real part in production today, or a proof-of-concept that soon could be. The goal is to provide a realistic picture of 3D printing’s capabilities and usefulness today, as well as a sneak peek at where it could go in the future.

What do these parts all have in common? Each has been the subject of an episode of “The Cool Parts Show”. Clockwise from upper left: topology optimized titanium spine cage; custom glasses with 3D printed frames; an ultra-high vacuum chamber for quantum physics research; and a parking brake bracket for the Ford Shelby Mustang.

Additive Manufacturing and Modern Machine Shop Editor-in-Chief Peter Zelinski is my cohost on the show. In each episode, we explore the details that went into making the part, as well as how it fits into larger themes like the Internet of Things, mass customization and sustainability. We strive to make every episode interesting and approachable whether you’re an AM pro or just curious about 3D printing.

There are two complete seasons of “The Cool Parts Show” out now, including episodes about all the “cool parts” mentioned above. Find them at thecoolpartsshow.com or on our YouTube channel; the full playlist is also embedded below.

Filming for Season 3 is already in progress, but in the more immediate future we’ll be releasing some special coverage related to COVID-19. We’re checking in with past subjects of the show to find out how they are adapting. A special episode is also in the works on what might be the biggest production story for additive manufacturing that we’ve seen, pandemic or otherwise: testing swabs.

If you want to be notified about new episodes, subscribe to our channel on YouTube or to the weekly AM Update e-newsletter. Stay tuned!

Related Content

-

Machine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.

-

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

-

Digital Transparency in Machining Key to Multi-Site Additive Manufacturing

Cumberland Additive’s CNC programmer in Pennsylvania spends most of his time writing programs for machine tools in Texas.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)