The Basics of Bar Pullers

Bar pullers are cost-effective alternatives to enable automated turning on CNC lathes. Learn how they work and how shops can benefit from using them.

Share

Takumi USA

Featured Content

View More

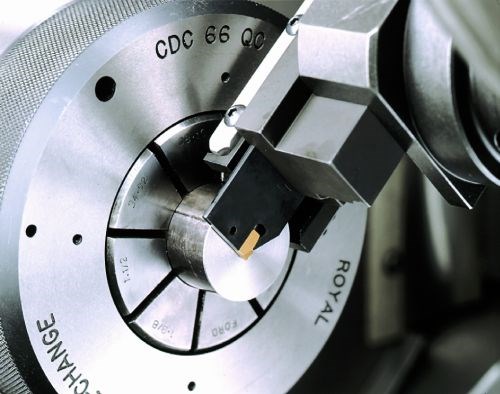

This combination bar pulling unit incorporates a cutoff tool so it occupies only one lathe turret station and eliminates an index from tool to puller.

There are multiple ways to automate a CNC lathe. If your goal is to gain lengthy stretches of unattended operation, then a bar feeder is hard to beat. Conversely, a bar puller is a cost-effective alternative for automated turning of small or medium batch sizes. That’s because a puller can free up sufficient time between bar changes to enable a single operator to tend multiple machines, measure critical part features or perform value-adding secondary operations. The resulting labor cost savings can quickly pay for the puller, as explained in this past article.

Related Content

-

Machining Vektek Hydraulic Swing Clamp Bodies Using Royal Products Collet Fixtures

A study in repeatable and flexible workholding by one OEM for another.

-

Using Jaws as Grippers Enables Flexible, Low-Cost Automation

VersaBuilt’s automation systems significantly boosted Innovative Fabrication’s revenue. In return, the shop has helped VersaBuilt optimize its products.

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)