Tecumseh Sets Its Course

A very different kind of CNC software paves the way for creating an integrated manufacturing environment.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

“A journey of a thousand miles starts with a single step.”

This ancient Chinese proverb is good to keep in mind when thinking about how a factory begins to move toward a plant-wide electronic production monitoring system. The vision of the future destination may be luminous and compelling, but turning this vision into reality is no hop, skip and a jump. It has to be taken earnestly and carefully, step by step.

In the end, plant managers will be able to access the system and get instant, up-to-the-moment reports summarizing the OEE (Overall Equipment Effectiveness) rating of the whole plant, separate production lines or even individual machine tools. Analysis of the collected data used to calculate this rating will pinpoint where problems or opportunities for improvement appear.

Here is an example of what is to come when a production monitoring system is in place: Managers are alerted to a report showing that a certain machine in one of the machining lines needed an average of 3 minutes cycle time during the last shift when it should have been closer to 2 minutes at programmed feed rates and spindle speeds. Reviewing the log of events that occurred during this shift shows that a grinding wheel was not cutting as aggressively as intended and had to be replaced at 50 percent of its expected life as a result of excessive wear. A recent change in wheel grade is recorded in notes entered by the manufacturing engineer. At the start of the next shift, a message to the cell operator gives instructions to install a harder grade wheel. Cycle times monitored during the day show a return to the required output. Problem solved.

This vision is not new. It’s been talked about and dreamed about for years. In fact, the software and hardware to make it happen not only exist, but they also have a proven track record. What is becoming clear is that making the transition to this future state will be neither quick nor effortless. The first steps are the toughest, but that is where the journey begins, as the proverb reminds us.

Tecumseh Products’ compressor plant near Tupelo, Mississippi, has taken those first steps, and the benefits are already clear and substantial. The plant has installed software-only CNCs on several “bottleneck” machine tools and is running key portions of a bidirectional production monitoring system that integrates the CNCs with the plant’s existing computer network and ERP software. Plant management is taking the results of these initial installations as proof that these steps are definitely moving in the right direction.

Under Pressure

Although Tecumseh Products is best known for its small engines found on leading brands of lawn mowers, snow blowers and similar products, the company is a major producer of compressor motors for refrigerators and air conditioners. Consumers are not likely to be aware that the reason these products run so quietly and efficiently is the unseen presence of a Tecumseh–built compressor inside, yet the reliable performance they enjoy is dependent on the quality of those compressors. Because many of the major brands of refrigerators and air conditioners have moved production offshore, Tecumseh has had to redouble its efforts to maintain profitable operation of its compressor plants in the face of the cost pressures brought on by the severe contraction in U.S.-based appliance manufacturing.

In Tupelo, Tecumseh operates three main machining lines that feed an assembly line on which the various compressor models are built in a mix that is determined by a schedule of firm customer orders. This plant houses about 100 active metalcutting machine tools. A shop control system that relies on manual data entry allows managers to monitor production, but the information is at least 1 day old by the time it is available for analysis and response. The system tells managers basic information about labor input, machine output and scrap rates. This gives them a somewhat sketchy picture of where the bottlenecks are and when part shortages may affect the assembly line. It is adequate to tell them how to react but rarely helps them anticipate and avoid shortages that hamper the assembly line. It can’t tell them what is happening inside each machine to reveal the causes of bottlenecks.

“What we have in place is now the framework for a much more capable production control and communications system,” says Joe Kulovitz, a manufacturing engineering manager.

The system will eventually supplant the existing one and provide a much more detailed picture of machine performance in real time. The new system has two main elements, both from Manufacturing Data Systems, Inc. (MDSI) in Ann Arbor, Michigan. One is OpenCNC, an open-architecture machine control that replaces OEM-installed CNCs. The other is MaximumFactory, a suite of software modules that collect and analyze real-time data generated at machine control units. This software suite is tailored for the ability of OpenCNC to extract data, but the software can also be interfaced (although less conveniently) with proprietary legacy CNCs.

“Our first step was to identify the bottleneck machines in each machining line and address the limitations created by outdated hardware and control technology,” says Mr. Kulovitz.

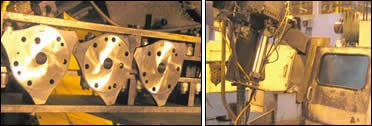

The best example of how the plant is systematically tackling these bottlenecks is in the grinding cells dedicated to machining the main compressor bearings for Tecumseh’s best-selling compressor model. These parts are critical to compressor performance. Flatness of the main bearing surface, its perpendicularity to the bore of the bearing shaft ID, the straightness of the bore center line and the roundness of the ID are all closely toleranced to ensure leak-free operation and long life of the bearing shaft. The part comes in three variations, depending on the length of the bearing shaft bore.

Originally, the cell consisted of six Bryant grinders that were automatically loaded and unloaded. Today, four grinders match the production of the original six. One of these machines has been retrofitted with OpenCNC and integrated to the network via MaximumFactory. It is largely because of the increased efficiency and uptime of this upgraded grinder that the cell remains viable.

David Clayton, the Tecumseh manufacturing engineer responsible for this retrofit, explains the situation: “The existing CNC on this machine was prone to failure because of its age. Repair parts were getting hard to find. And even when it was running, the interface with the parts loader ran slowly, killing our cycle time.” Mr. Clayton oversaw installation of the new control in 2000. He says that the grinder now has a much better record than the other grinders, reporting that the retrofit grinder produces 50 parts per hour compared to the 40 parts produced on each of the other machines. The retrofit machine typically runs 9 out of 10 hours in its normal shift, whereas the other machines average 4 or 5 hours in the same period.

According to Mr. Clayton, the improved performance of the new CNC on the retrofit grinder is entirely attributable to its special software. The CNC hardware is “special,” too, but only because it is simply a standard office-grade personal computer mounted in the electrical enclosure of the machine.

“The PC handles everything—one processor closes the servo loop in real time, runs the operator interface, drives the I/O and acts as automated data collector and transmitter,” Mr. Clayton says. No proprietary motion control card or other device not available off the shelf is involved.

An Early Adapter

Tecumseh Products, which has its corporate headquarters in Tecumseh, Michigan, was an early customer of MDSI. Having installed the software-based CNCs on several machines in its Michigan small-engine plants, Tecumseh saw the advantages of this approach to machine control. However, the main appeal was more than the value of CNC technology. The company saw that from the beginning, MDSI was dedicated to enhancing overall factory management, with the software-based CNC being just one piece of enabling technology. A CNC that could record the electro-mechanical happenings that occurred during the execution of a machining program would automatically create a database for distribution across a plant-wide network. This database would then be the basis for monitoring and actively controlling shopfloor production on a real-time basis.

Top managers at Tecumseh also recognized the larger value of such a plant-wide system. In fact, the concept of a software-based CNC as the basis for plant-wide monitoring and control were deemed so essential to Tecumseh’s long-term strategy for revitalization that the company acquired MDSI as a subsidiary. Todd Herrick, president of Tecumseh, says that by acquiring this CNC and factory integration developer, his company was guaranteed access not only to the technology, but also, and more importantly, to the larger vision of an integrated factory management system. Of course, the acquisition was also seen as a sound business investment: As a Tecumseh subsidiary, MDSI continues to develop and market its software products for the general manufacturing industry.

“Our goal is to put in place a global, Web-based platform running the same production control software worldwide,” Mr. Herrick says. “We have the source of that software in MDSI.”

Events Happen

Joe Petsche, an MDSI software engineer who has been involved in the Tupelo installations, puts the practical aspects of reaching this goal into perspective. “We believe that effective factory integration hinges on two key insights. One is that the most important information about production is generated right in the CNC itself. Second, the CNC has to be structured to make this data readily available to the network software.” Limited access to the data from the machine tool will hamstring other approaches to factory monitoring and control, he warns.

The grinder in Tupelo is a case in point. Software running in the PC keeps a continuous log of events that occur during operation. This feature, which MDSI calls Significant Events, allows the user to program the CNC to detect the occurrence of a machining event, give it a readable label and mark it with a date and time stamp. Machining events can be just about anything the machine tool does on command, such as opening and closing a relay, changing a tool, starting or finishing a machining cycle and so on. Moreover, by inserting a simple macro routine in the part program, the programmer can make the CNC send messages across the network when a certain predetermined event occurs.

For example, the grinder automatically keeps track of each time the main grinding wheel is dressed. When a preset number of dressing cycles is reached, a pop-up window automatically appears in the display panel, reminding the cell operator to change wheels. The grinder will automatically shut down if the wheel has not been changed before another set limit is reached. The CNC can also be set up to send an e-mail message or activate a pager signal, notifying a supervisor of a production stoppage.

With a software-based CNC, collecting and distributing data from the machine tool in real time is an automatic result of running the machine. Data collection does not require operator intervention or specialty hardware and software, which are important cost considerations at the Tupelo factory.

Out To The Network

Although a log of machining events is useful to a non-networked machine tool, getting the data on a network unlocks its full potential. According to Mr. Petsche, because the Tupelo plant had an existing Ethernet network in place, connecting the new CNCs to that network was simply a matter of connecting the network cable to the PC’s standard communications port and the Ethernet card inside. Working with Mr. Clayton on installations, Mr. Petsche loaded a MaximumFactory application program called MAXOmni into the PC memory and set it up to launch whenever OpenCNC is launched.

MAXOmni runs in the background while a CNC part program is being executed. It categorizes events being logged and transmits the data to a central database server. This application software at the CNC also reports to the operator, displaying messages and alerts as needed. The operator also uses this software to enter inspection data from the gaging station located in the grinding cell.

The central database server runs other application software to organize and summarize incoming data from all OpenCNC units on the network. This software generates reports formatted in HTML, the language for displaying information as a Web page on the company’s intranet and the Internet. This makes the information accessible to any user authorized to log in with a password.

Currently, Mr. Kulovitz can log onto the network from his desktop PC and access a variety of reports summarizing activity at the grinder, or at any other machine tool interfaced with the network. One of these reports calculates the Overall Equipment Effectiveness for the grinder. OEE is a formula that combines the machine’s availability (a measure of uptime), its performance (a measure of usable output) and quality (scrap rate). If the OEE is not as expected, he can look at reports representing the various OEE factors to pinpoint the cause. He can “drill down” further into the database to review the log of events to find a possible problem, such as an excessive number of wheel changes.

Eventually, when all of the machine tools are interfaced with the production monitoring system, Mr. Kulovitz and other production managers will be able to track OEE at the plant level, on any of the machining lines and on the assembly line. Because the most troublesome bottleneck machines are already being monitored, the assembly line has had far fewer stoppages resulting from the machining lines not being able to meet production goals.

Other Prongs

Tecumseh’s Tupelo plant has more than this transition to an integrated production system going on. The plant is also implementing lean manufacturing and Six Sigma in a three-pronged approach to factory revitalization. Lean manufacturing is a systematic effort to remove waste from all plant operations. Six Sigma is a systematic effort to remove variations from the output of plant operations.

MaximumFactory will enable plant managers and corporate executives to measure and relate the results of these other two initiatives in a coherent, meaningful way. More importantly, the software provides a tool for identifying areas where the best opportunities for further improvement exist.

“We’ll have a sort of current state map that is truly current,” says Mr. Kulovitz.

As of October 2005, the plant had 12 machine tools equipped with the software-only CNCs and interfaced to MaximumFactory. This number represents mostly grinders, including a large creep feed machine, but several lathes and milling machines have also been added. More machines are slated for updating as soon as a re-engineering of certain compressor models is completed in the near future.

Although many factory managers are talking about tapping into the data that is created by CNC machine tools and other automated production equipment, Mr. Kulovitz’s plant is actually doing it. At times, it seems that the plant has only scratched the surface, he says, but there is nothing superficial about how far or how deeply the planned integration can go. “We know how to capture the data we need and how to use it to make the plant more efficient and productive,” he says.

This confidence is a real boost. In short, this factory’s first steps toward total integration are giving it a running start and the momentum to keep the progress going.

Related Content

Finding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read MoreFinding Skilled Labor Through Partnerships and Benefits

To combat the skilled labor shortage, this Top Shops honoree turned to partnerships and unique benefits to attract talented workers.

Read MoreAddressing the Manufacturing Labor Shortage Needs to Start Here

Student-run businesses focused on technical training for the trades are taking root across the U.S. Can we — should we — leverage their regional successes into a nationwide platform?

Read MoreHow to Pass the Job Interview as an Employer

Job interviews are a two-way street. Follow these tips to make a good impression on your potential future workforce.

Read MoreRead Next

What Does It Take To Internet-Enable Machine Tools?

It takes data—complete machine and process data from a machine tool that is easily linked to a factory network and easily exported.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)