Taiwan’s Aircraft Ambition

Various machine tool builders in Taiwan eye the aircraft industry. Some have formed an alliance that is now working with a research institute to tailor machines for more effective processing of aircraft workpieces.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View MoreFor Taiwan, making aircraft parts represents a promising avenue for future growth. The island is already well established in sectors such as automotive manufacturing, but it still has plenty of room to advance in the aircraft industry. Yet one important challenge in profiting from that advance relates to the machines that make these parts. Taiwanese aircraft part makers often do not use Taiwanese machine tools, but instead rely more on Japanese, German and other foreign-made machines that have a proven history in aerospace part production. If Taiwan’s machine tool builders could increase their share of the country’s own growing aircraft part-making activity, the result could be a big win for these builders—particularly since the machines developed through this effort would be attractive to foreign aircraft part producers as well.

With that objective in mind, a group of machine tool makers in Taiwan recently formed an alliance—through the country’s Ministry of Economic Affairs and coordinated by Goodway Machine Corp.—aimed at developing machine tools specifically for aircraft part machining.

The 11 companies in this alliance are working with the government-supported Industrial Technology Research Institute (ITRI) on this effort. ITRI is a 6,000-employee organization serving various industries, but one of its facilities is the Machine Tool Technology Center in Nantou City that routinely works with Taiwanese builders on developing and proving out new capabilities and improved designs for their machines. ITRI’s Derek Luo, Ph.D., a machine tool engineering specialist at this center, says the goal is to continue advancing Taiwanese machine tool offerings into higher levels of technology while maintaining the low pricing that is associated with Taiwan.

The aircraft-related development work has focused on 20 different aircraft components, he says, including parts exemplifying fuselage members, wing spars, turbine engine casings, turbine blades and blisks. Through machine tool structural analysis, digital simulation, machining process optimization and CNC software development, ITRI is helping Taiwanese builders tailor machines for improved performance, specifically as it relates to these aircraft components. The benchmark is to realize machines and processes that improve upon the lead times and cycle times local manufacturers of these components are achieving on their current high-end machines.

During a recent stay in Taiwan, I met with various builders that have their eyes on aircraft part machining, both within and apart from this alliance. In the photos below is some of what I saw.

Royal Precision Tools Corp.

|

|

Left: Spindle production at Royal Precision Tools Corp.; Right: I talk with Oliver Tsai, general manager.

The spindle is the most important component of the machine tool, says Oliver Tsai, general manager of Royal Precision Tools Corp., the only spindle maker in the aircraft-industry alliance. “If the machine was a person, it would be the heart.” Domestic production of aircraft-component machine tools therefore requires domestic production of spindles for these machines, he says. Royal, which produces more than 30,000 spindles per year, largely for manufacturers in China, is working with ITRI to create a spindle very different from its typical offerings. “We are using science,” he says, not previous practices or assumptions, in order to predictively design a spindle according to the needs of high-speed aerospace milling. Frequency response function is an important part of this. The spindle’s dynamic stability will be tailored to the cutting conditions favorable to efficient milling of large aircraft structures.

Victor Taichung Machine Works

|

|

Left: I speak with Wayne Hsueh, director of Overseas Marketing Division at Victor Taichung Machinery Works; Right: Production of a lathe's turret.

Victor Taichung Machinery Works’ R&D Division director Johnson Lu comments that it is difficult for any individual machine tool builder not established in aircraft part machining to approach the companies in this sector. The value of the alliance and the shared connection to ITRI is that this collaboration makes it possible for the companies involved to approach the aerospace industry as one, with a shared commitment to developing technology that this sector needs. Five-axis machining for blade production is one of Victor’s focuses in this area. The company is proving out processes on its AX800 five-axis vertical machining center for machining blades efficiently. The company’s Overseas Marketing Division director Wayne Hsueh says vertical integration is one of the strengths that makes Victor distinctive and what enables it to respond quickly to customers’ demands for more options in five-axis and turn-mill machines. That integration extends back to casting—the builder is one of two in Taiwan that has its own foundry. The right photo above shows production of a lathe’s turret, a part the company used to order from a supplier but now manufactures in-house.

Goodway Machine Corp.

|

|

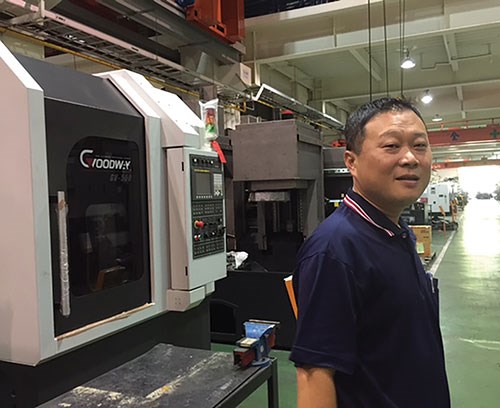

Left: A vertical lathe made by Goodway; Right: Jeff Peng, sales manager.

Goodway makes turning machines, including vertical lathes appropriate to combustion cases, such as the one shown at right. Its subsidiary Awea makes machining centers being applied to blade milling. Goodway sales manager Jeff Peng says about 20 percent of the company’s workforce is involved in R&D. For the aircraft-related R&D, the company’s own internal research focuses on questions such as how much cutting force and torque are ideal for the representative parts, and what machine platform is the most cost-effective in each case. ITRI is then able to take this information to help Goodway digitally develop a machine structure tailored to that needed level of performance.

YCM

YCM's on-site foundry.

For efficiently machining challenging workpiece materials, one of the advantages YCM relies on is an in-house foundry located on the same property as the machine tool plant. The on-site foundry shortens the development cycle of new machine designs that have castings engineered for heavy milling of aerospace alloys. The foundry and machine tool plant are located adjacent to one another thanks in large part to the foresight of the company’s founder (grandfather of the current chairman) in obtaining such a large parcel of land when the company began.

A machine being built by YCM specifically to suit aircraft component production.

Richard Chen, chairman of YCM, cites customization and challenging workpiece materials as two of the factors important to serving the aircraft sector. His company is not part of the alliance but is making its own efforts to increase its responsiveness to the needs of aircraft-industry customers. The customization he refers to is often relatively minor but still has to be performed cost-effectively within the company’s production process. The machine seen in the photo above, for example, is being built with table and travels that are shorter than its standard specifications to match the length of the aircraft component to be produced on this machine.

Asia Pacific Elite Corp. (APEC)

APEC's large gantry machine for aircraft parts is driven by linear motors.

Asia Pacific Elite Corp. (APEC), founded in 2001 and now part of the Tongtai Group, makes a type of machine not typically associated with Taiwanese machine tool builders: a large gantry machine driven by linear motors. Aircraft machining is the principal focus of the machine, but it is also effective for machining large dies or molds, which is where many of the sales have been. Winning the trust of aircraft-industry customers to the point of being considered by them for the purchase of an important machine making critical components is a difficult, long-term effort, the company says. Die/mold sales are easier, but in the die/mold application, there is little potential for the customer to need more than one machine. Olivia Sung, APEC’s marketing and sales department manager, says, “In aerospace, the first machine sale to the customer is extremely difficult. But in die/mold, the first machine sale is all you get.” One promising collaboration the company has had with an aircraft-industry manufacturer in Taiwan involved turbine case machining. APEC developed a compact five-axis head able to fit entirely inside of the ID of the part so that all of the required ID machining can be performed without resorting to a series of head changes and tool extensions. The head is more expensive because of the spindle that this compact design requires, but it makes up for its cost in the simplicity and time savings of the machining cycle.

Tongtai Machine & Tool Co.

Inside Tongtai's headquarters factor in Kaohsiung City.

Tongtai, the largest machine tool builder in Taiwan, is part of a group that has grown through acquisition and partnering in recent years. The Tongtai Group not only includes Taiwanese builders such as APEC (mentioned previously), but now also includes European builders Anger and PCI. The machine tool production capacity at the Tongtai Machine & Tool headquarters factory in Kaohsiung City is also growing. Jack Ting, overseas sales department deputy manager, says that while the company has been the most successful with horizontal machining centers in the U.S. market, a new factory being built on its current site will increase its capacity for producing large machines, including those being used in Taiwan to make large aircraft parts such as engine casings. The company is also developing additive manufacturing machines. (More on this at gbm.media/taiwanam).

Chung Hsin Electric & Machinery (CHEM)

A large CMM at Chung Hsin Electric & Machinery (CHEM).

Alliance member Chung Hsin Electric & Machinery (CHEM) is a large, established manufacturer of power generation and other industrial equipment that launched a group for producing and marketing large, linear-motor-driven five-axis gantry machine tools in 2010. Because the parent company is a manufacturer in its own right, it produces some machines for its own use. It also found a route it hadn’t planned on for building relationships within the aircraft industry. Two major aircraft parts makers in Taiwan both observed that CHEM had the gantry machine tool and had the production facility, so they asked if it could take on overflow machining work. CHEM said yes, and the company eventually started an additional division for contract manufacturing of machined parts. The machine seen in the photo at the top of this article is used for contract machining, including machining of aircraft components inspected on the large CMM above. Running work onsite for customers in this way gives those customers a chance to come see the machine in use and monitor its performance producing their own parts. As a result of this kind of interaction, each of those aircraft part makers employing CHEM for overflow machining has since purchased one of the company’s gantry machines.

Related Content

Bavius Technologie Appoints New President, Schedules Technology Showcase

Roy D. Cripps will lead the team at Bavius as it aims to expand its current business in aerospace structures and develop new market segments. Additionally, the company will showcase its technology during an open house event on June 11.

Read MoreLyndex-Nikken Collets Enable Accurate Small-Diameter Cutting

The MMC Mini-Mini collet chuck is well suited for high-speed machining applications where clearance is needed, such as die mold, aerospace and medical parts.

Read MoreArch Cutting Tools Acquires Custom Carbide Cutter Inc.

The acquisition adds Custom Carbide Cutter’s experience with specialty carbide micro tools and high-performance burrs to Arch Cutting Tool’s portfolio.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)