Swiss for Short

A Swiss-type lathe with a B-axis milling spindle and significant tooling capacity enables this shop to be more effective at complex, short-run work—work the shop otherwise might not even bid on.

Share

All those who assume that today’s U.S. manufacturing operations resemble the dark, dingy and dangerous factories of yesteryear should be made to visit machine shops such as Magnus Precision Manufacturing.

The company’s facility in Phelps, New York, features a shop area that’s clean, organized, well-lit and environmentally controlled. The machining equipment there is top-notch and well-maintained, too, with features such as 0.00001-inch programmable resolution capability, glass scales, spindle chillers and high-pressure coolant systems. The shop even has a couple five-axis machines in its prototype department. That way, if a prototype project results in a production run, the shop has an effective machining process already completed, including programming, tooling and workholding.

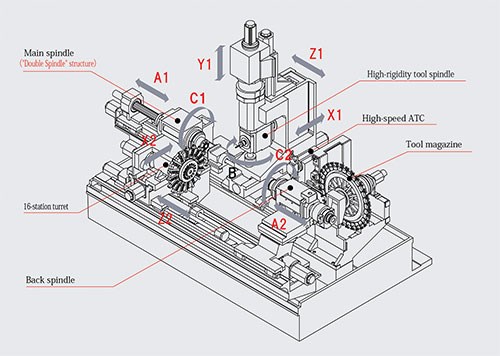

All this capacity, combined with a highly skilled, veteran staff, enables the shop to perform complex machining work often requiring accuracies in the low tenths for customers in the aerospace, medical, optical and photonics industries. But what is equally impressive about Magnus is the gutsy nature by which it adopts new machining technology and equipment platforms. A recent example is the big Swiss-type lathe that it purchased five years ago. It bought the machine even though the only person on staff who had any experience with a sliding-headstock lathe was a manufacturing engineer who previously owned a shop that used similar equipment. In addition, the Swiss-type lathe Magnus purchased is not what you’d consider an entry-level model. It features a sizeable 1.5-inch bar capacity, 12-foot bar feed, a B-axis milling spindle with 60-tool automatic toolchanger (ATC), 1,000-psi high-pressure coolant delivery, and tool monitoring and adaptive control system.

Don Miller, director of business development for Magnus, says the point of this investment was to enable the shop to more effectively machine small batches of long, complex parts that required turning and milling operations—the types of low-volume jobs it otherwise wouldn’t pursue because of the multiple setups that might be needed. Of the specific machine features mentioned above, the two that are particularly valuable in this respect are the B-axis milling spindle and significant tooling capacity.

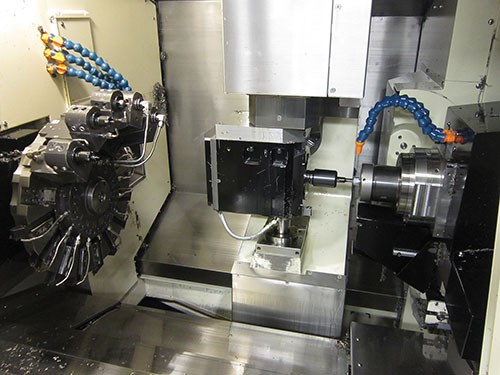

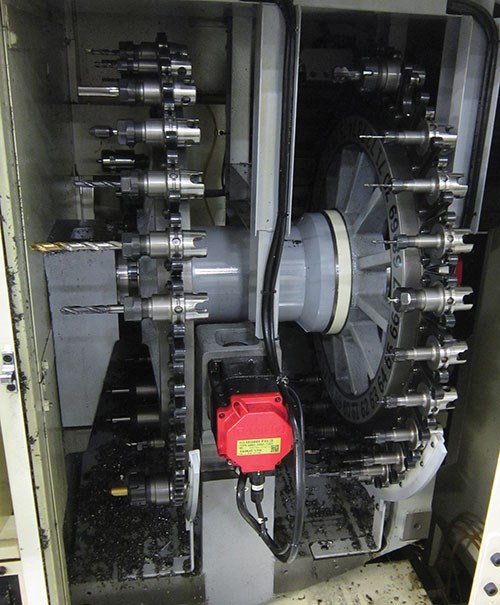

When using the B-axis milling spindle, this Swiss-type lathe essentially becomes a five-axis turn-mill with the bonus of a sliding headstock. The sliding-headstock is what enables the machine to effectively turn long parts with small-diameters, while the B-axis milling spindle can approach workpieces in the machine’s main or subspindle at a variety of angles. This makes it possible to eliminate secondary operations by machining parts complete. In addition, the machine’s 76 tooling stations (there are 60 in the B-axis spindle’s ATC and 16 in the turret) enable tools for multiple jobs to be loaded all at once, resulting in fewer setups, less machine downtime and higher overall productivity.

Mr. Miller says that the Swiss-type platform nicely complements the shop’s other multifunction equipment. In fact, this addition at Magnus is representative of a growing trend whereby non-screw-machine-type shops are recognizing the advantages that Swiss-type lathes offer for producing long, tricky parts complete as well as more prismatic parts that require a good deal of milling and drilling operations, too.

Adopting Advanced Technology

Magnus was founded in 1982 and now is a subsidiary of Floturn Inc. The 100-percent employee-owned shop is ISO 9001:2008-certified and AS9000-compliant, and has a 55,000-square-foot facility near Rochester, New York. It has quite a mix of machining capabilities, including five-axis machines, twin-spindle/twin-turret lathes, HMCs, VMCs with integrated pallet systems, and wire and sinker EDM equipment. Magnus machines materials common to most shops as well as more exotic materials such as high-temperature alloys, titanium, stainless steel, magnesium, beryllium copper and aluminum beryllium. Typical lot sizes don’t exceed 300 pieces.

Around 2009, the shop was more frequently being asked to produce small batches of relatively long, small-diameter parts requiring turning as well as milling or drilling. Mr. Miller, who is also the coordinator for new equipment purchases at Magnus, says the shop took on some of this work using mills to perform the requisite secondary operations. However, it couldn’t be competitive on other jobs because of the time-consuming multiple setups that were required. This spurred the shop to look to more appropriate equipment for machining these parts, and a Swiss-type lathe seemed ideal.

While carefully considering a number of Swiss-type brands and machine models, it was decided that the Tsugami TMU1, available in the United States through REM Sales (Windsor, Connecticut), offered the best mix of features for the shop’s needs. Like all other Swiss-type lathes, the TMU1 has a sliding headstock. Ground barstock is fed through the headstock inside a guide bushing instead of feeding the tool. This means an OD turning tool cuts the stock near the guide bushing (and point of support) no matter how long the workpiece. The machine feeds the work out of the spindle and past the tool as it goes, and the part is essentially completed in sections. This makes the CNC Swiss-type particularly effective for long and slender turned parts that would otherwise deflect if supported by a center on a conventional lathe.

In terms of Swiss-types, the nine-axis TMU1 is a sizeable unit that accommodates 1.5-inch-diameter barstock. Both the main and back spindles offer 6,000 rpm, 11/7.5 kW of power and full C-axis capability. The main spindle features the OEM’s “double structure” design, which is said to enable heavier cuts near the guide bushing. The machine has a 16-station turret that serves the main spindle.

Of course, the signature element of this machine is its B-axis milling spindle. This differs from conventional Swiss-type designs that use gang-style tools that are fixed in their orientation with the part, either perpendicular to the face or diameter of the barstock.

The 5.5-hp, 10,000-rpm spindle offers 210 degrees of B-axis rotation (±105 degrees) and is mounted on a column that also provides linear X, Y and Z motion. B-axis rotation possible in 0.001-degree increments enables the spindle to approach a workpiece held in the main or subspindle from a variety of angles. Therefore, it can perform operations such as drilling at angles that aren’t normal to a surface as well as 3 + 2 and full five-axis contouring. This is ideal for parts with angular features, contoured surfaces, features off the centerline and tight geometric-positioning tolerances. The subspindle enables back working to be performed as well, so parts can be machined complete. That said, the B-axis spindle can also function in a “static” mode to enable operations such as pinch turning in conjunction with the turret.

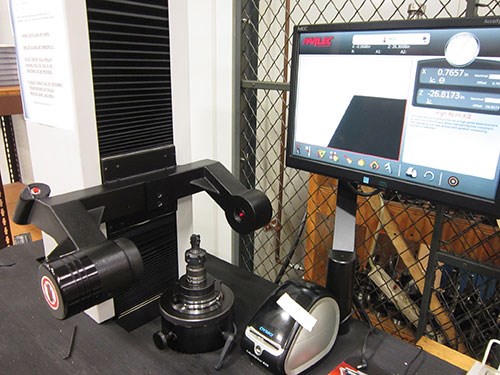

The B-axis spindle has a KM40 taper and is supported by a 60-station ATC (30 is standard for this machine). Will Breen, the TMU1 programmer and operator, says the added tooling capacity is important for minimizing setups, because tools for multiple jobs can be loaded at one time. Rather than performing a setup for each job, one setup routine can support many jobs, maximizing machine in-cut time. A Parlec tool presetter enables easy input of tool offsets during setup, eliminating the need to touch-off tools.

Despite the large tooling capacity, Mr. Breen says he still tries to minimize the number of tools used. He does this by dedicating stations to specific tools/operations (roughing, finishing, grooving, etc.).

Getting Better

Mr. Breen had experience with Magnus’ traditional turning centers as well as its custom-built Mazak twin-turret/twin-spindle turning center, but had no experience with Swiss-types prior to being selected to be TMU1’s programmer and operator. He says that because of the way that sliding-headstock lathes complete parts in segments, an early challenge was mapping out programming strategies for parts prior to actually creating part programs. For some jobs, Mr. Breen uses PartMaker CAD/CAM software. Now that he’s since built up a library of proven programs that have run on the TMU1, though, he also has the option of modifying existing programs from similar jobs, essentially cutting and pasting code to generate a new program.

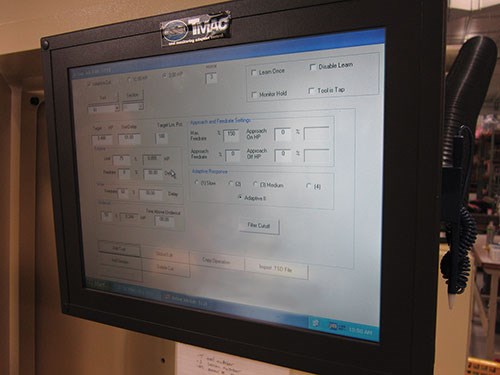

With a few years of experience with this machine under his belt, Mr. Breen often identifies ways to improve part programs for repeating jobs and is becoming better at choreographing operations to run simultaneously. He also recognizes the value in applying the Tool Monitor Adaptive Control (TMAC) system from Caron Engineering more often. The TMAC system uses a multi-range sensor to measure spindle horsepower during cuts to determine when tools are worn or broken. A monitor installed on the TMU1 offers real-time data viewing and also time stamps all monitored events. Its adaptive control capability automatically adjusts the feed rate for each tool to maintain a constant horsepower in the cut as the tool wears. By adjusting for varying cutting conditions in this way, the system enables the tool to cut at its optimum power level. Mr. Breen commonly uses the system for aggressive roughing operations, and says it helps maintain process consistency by adapting to tool wear while ensuring a broken tool doesn’t lead to a crash during a subsequent operation. It is also helpful when running the machine lights-out.

To date, Mr. Breen has advanced nicely up the Swiss-type learning curve and is starting to train others at Magnus to operate the TMU1. This is important because the benefits that Magnus has realized with its Swiss-type has it considering adding others at some point.

Related Content

TTI Brings Specialty Gear Production In-House with Multiaxis Machining

By investing in a 3+2-axis machine and utilizing simulation software for diagnostic checks, Techtronic Industries turned a four- to ten-week lead time into a one- to two-week lead time.

Read MoreWFL Milling Machines Feature Smart Sensors, Control System

M50 Millturn / 3,000 mm and M80X Millturn / 4,500 mm turning-boring-milling machines come equipped with a grinding attachment and a vibration-damped Silent ToolsTM Plus boring bar.

Read MoreHow to Meet Aerospace’s Material Challenges and More at IMTS

Succeeding in aerospace manufacturing requires high-performing processes paired with high-performance machine tools. IMTS can help you find both.

Read MoreMachine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More