Stiffness Improvement at Interface Leads to Spindle Life Increase

How the tool was clamped affected the spindle’s life because of the way the user naturally attempted to overcome the stiffness limitation, says tooling company.

Share

What is the connection between the toolholder interface and the life of a machining center’s spindle? Offhand, it doesn’t seem like there should be a connection. How long the spindle performs effectively is different from the means by which it holds tooling.

But according to Bill Redman, global product manager for tooling systems with Kennametal, a Tier-One aircraft-industry manufacturer recently observed a significant increase in spindle life when it retrofitted milling spindles in its facility to the tooling company’s KM4X toolholder system. Certain machines had previously required spindle rebuilding every six months. That level of frequent spindle maintenance stopped.

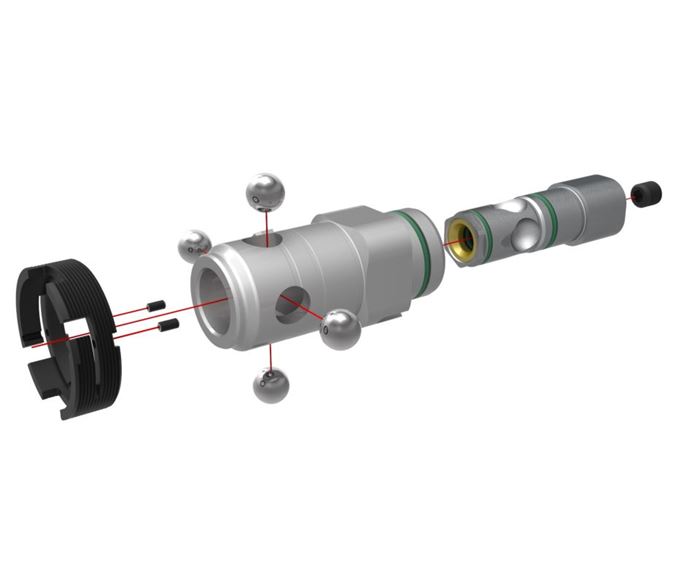

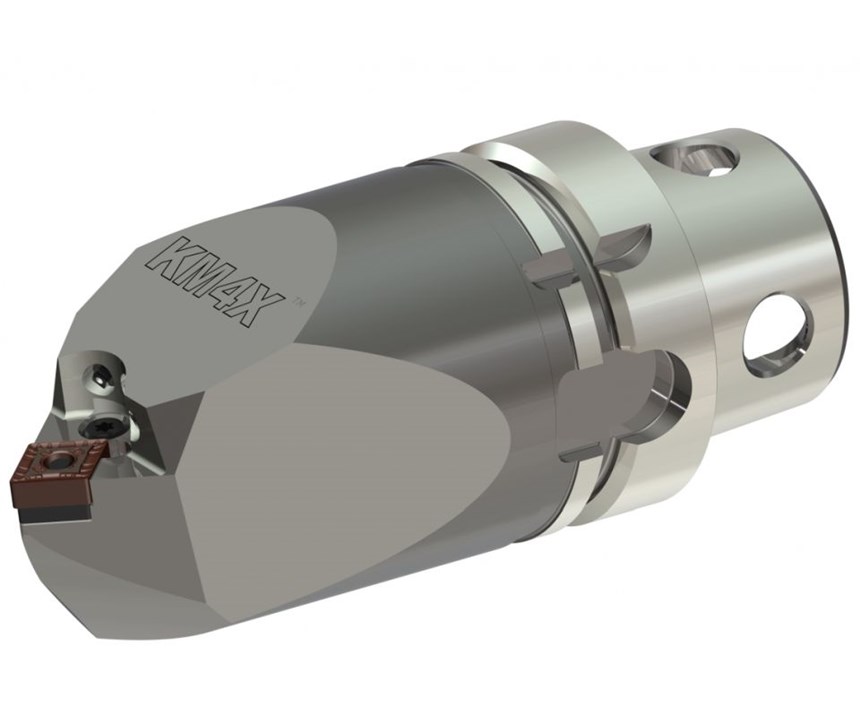

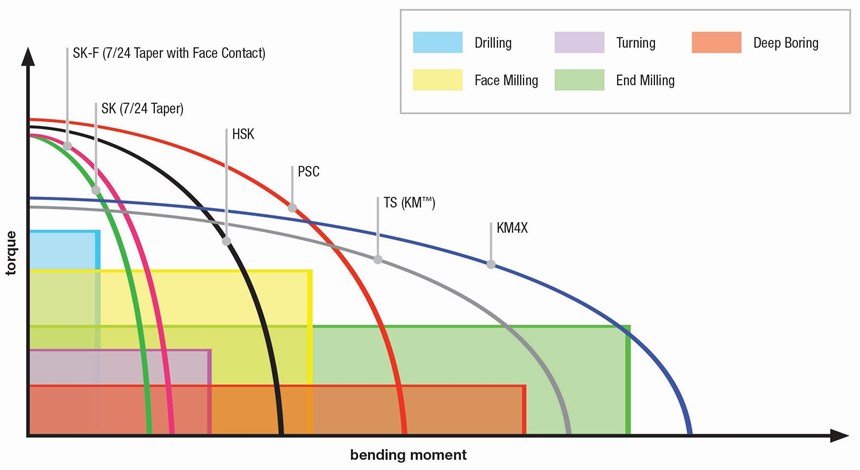

Designed for quick change on heavy-duty spindles, the KM4X system uses four locking balls (as opposed to two on an earlier, smaller version of this system) to achieve fast, precise clamping of the toolholder into the spindle. Significantly, the four-ball lock also provides for high bending stiffness—and this is the reason for the spindle life increase, Mr. Redman says. Previously, to try to compensate for low bending stiffness in heavy cuts, the manufacturer was over-clamping its conical toolholders. The resulting bell-mouthing of the spindle led to the spindle failures. Thus, it wasn’t literally the toolholder interface affecting spindle life, but the user’s response to the limitations of that interface.

Applicable to non-rotating tools as well, the KM4X system can also provide high bending stiffness for tools such as long boring bars, Mr. Redman notes.

Related Content

-

Shoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

-

High-Feed Machining Dominates Cutting Tool Event

At its New Product Rollout, Ingersoll showcased a number of options for high-feed machining, demonstrating the strategy’s growing footprint in the industry.

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

.jpg;maxWidth=300;quality=90)