Low-cost overseas competition continues to loom as one of the greatest threats to U.S. mold makers’ business, and Pittsfield, Massachusetts-based Marland Mold is no exception. For a shop like this, survival often depends on meeting conflicting demands—parts must not only be virtually flawless, but also produced and delivered quickly. In the face of this challenge, Marland says it relies on a culture of employee responsibility and a deep understanding of its customers to maintain a competitive edge.

Underlying, that, of course, are the CNC machines, measuring equipment and other manufacturing technologies employed at the company’s 84,000-square-foot facility. One particularly important tool is the CimatronE CAD/CAM system from Cimatron Technologies (Novi, Michigan). According to the company, the software’s easy-to-use modeling tools, powerful postprocessors, simulation capability and other features help streamline the manufacturing process from design through final machining. More recently, it has eased the shop’s adoption of five-axis machining, a move that has eliminated most EDM work.

Marland Mold’s core business is manufacturing high-precision closure molds for food and beverage industry customers located throughout the world, although it also serves the personal care and cosmetics; medical and pharmaceutical; and household and industrial products sectors. The shop attributes much of its success to its hands-on approach to business, a legacy of being independent and employee-owned from 1992 until merging with French firm Curtil late last year. Every customer project starts with the assignment of a team consisting of a sales executive, a design engineer and a manufacturing VP. This strategy gives front-line employees a stake in outcomes and encourages close collaboration with customers in the effort to develop a mold concept that meets their individual needs, the company says.

However, even with the best possible mold concept, cost-effectively turning designs into reality can be challenging. Most of the tools manufactured here require stringent quality standards, tight tolerances and interchangeable components. Consider the food and beverage industry customers that constitute the company’s core business. To support high-volume closure production, tools for these customers must run 24 hours a day, 7 days a week. Recent industry trends present additional challenges. Driven by the need for updated designs, faster cycle times, lower costs and more environmentally friendly products, customers are designing smaller, more elaborate caps made of thinner plastics.

To meet these requirements, Marland relies on a lean production strategy and advanced CNC machines and measuring equipment. CimatronE CAM software ties the whole process together, and the system begins to play its part as soon as a mold design is finalized, says John Nykorchuk, senior NC programmer. The process begins with a solid model of the mold in question, a model that Cimatron can read regardless of the originating design system, Mr. Nykorchuk says. He adds that whether creating a model within Cimatron or repairing a model that originated in another system, the software’s tools make alterations easy. This is important for Marland because the company rarely encounters common shapes. Rather, webbed, blended and other such surfaces are common, and the company is often forced to deal with holes and other glitches. “The software has all the tools we needs to alter, change and extend surfaces to machine a part the way we want,” he says.

Once the model is finalized, it is brought into Cimatron’s NC package for toolpath creation. At this stage, the ability to reuse common machining strategies is a significant time-saver, Mr. Nykorchuk says. Once a particular machining routine is finalized, the programmer can store that procedure in a template that can be recalled again as needed. This enables programmers to apply the same machining strategy to completely different part. Speeds, feeds and other parameters all carry over.

While saving programming time has made a significant impact at Marland, one of the software’s most important benefits is realized only after tool paths have been created. That is, the confidence that all the machines on the shop floor will be able to interpret tool paths generated in Cimatron. This is especially notable considering the fact that the shop uses three different types of CNCs, Mr. Nykorchuk explains. “I now have some of the best postprocessors I’ve ever had—no more editing. We can go back and forth seamlessly be-tween different applications, and that helps us streamline the entire process. Even our quality control department is working from the same 3D Cimatron model.” He adds that the ability to customize posts is also useful. This enables programmers to eliminate errors and the need for manual edits by adding special features to the posted output.

Moreover, the shop avoids postprocessor headaches when integrating new equipment, as it did a few years ago when it brought in its first five-axis machinery. During this period, Marland invested in a few different machine models from separate builders. With no prior five-axis experience, the transition was painful enough without having to worry about whether the machines’ CNCs could interpret Cimatron’s output, says industrialization team manager Jay Cairns. “The versatility to expand our manufacturing base using a single CAM package is an important benefit,” he says.

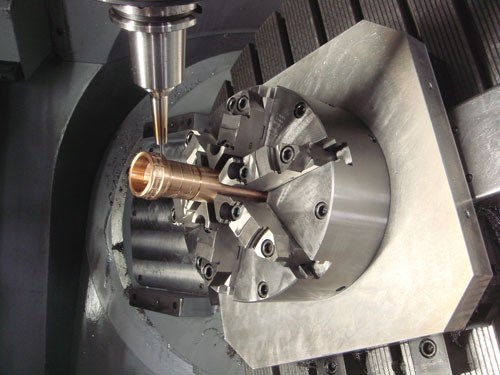

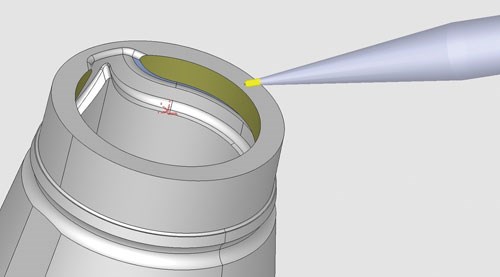

The effects of adding five-axis capability have been dramatic, Mr. Cairns says. First, the ability to machine parts complete on one machine avoids multiple, time-consuming setups and the associated stack-up errors. Also, the ability to reach into difficult-to-access features with small tools has eliminated much of Marland’s EDM work and everything associated with it, including electrode design. Finally, the ability to get closer to cavity and core surfaces improves cooling and cycle times.

Mr. Nykorchuk points out that effective postprocessors weren’t the only Cimatron feature that helped the shop realize these five-axis benefits. “The software is powerful enough to handle the complex designs we get from our customers, yet easy to operate,” he says. More specifically, he says the ability to place new coordinate systems over the part at any angle eases the programming of components with complex geometries. Additionally, the software’s simulation capability ensures that complicated five-axis operations proceed as planned. This provides a smooth transition from programming to the shop floor because operators can trust programs without having to prove them out. It also enables the shop to run its five-axis machines unattended with complete confidence.

.jpg;maxWidth=300;quality=90)