Shop’s New Combination Lathe Offers Increased Flexibility, Capabilities

JBC Machine’s older combination lathe lacked precision and reliability. A Weiler E50 flat-bed lathe with conversational control and Parat toolpost system brought tighter tolerances, simplified threading operations, and higher torque and rigidity.

Share

The more capabilities a machine has, the more productive and efficient it can be. When JBC Machine wanted to replace its increasingly unreliable combination lathe, it chose a Weiler E50 flat-bed machine that can function as a manual or programmable lathe. The company says it holds tighter tolerances, offers simplified threading capabilities, and provides more rigidity and spindle torque, and these capabilities have translated into faster part programming, speedier thread repair and the ability to use bigger tooling for heavier cuts.

Founded in a garage in 1985, JBC has grown from one manual machine and one operator to a facility in Hortonville, Wisconsin, with 25 employees and a variety of machines, including six VMCs, two CNC lathes, three knee mills, and two turning centers with Y-axis and live-tooling capabilities. At first, its core market was the paper industry, and its second-largest customer is still Voith Paper, but its current primary customer is an aerospace company.

Until about two years ago, the shop had been using a 17-year-old combination lathe for much of its basic turning work, but according to JBC Vice President Aaron Harvey, the old lathe’s electronics were becoming unreliable and it was having difficulty holding tolerances. Finding replacements for broken components also was becoming more difficult. “It was getting tired,” he says.

So Mr. Harvey went to the Wisconsin Machine Tool show looking to replace the aging machine with a new combination lathe. There, Mike Weller from distributor Weller Machinery introduced him to the Weiler E50 lathe, which can function as both a manual and a programmable machine.

“A lot of the operations we do are manual operations,” Mr. Harvey says. For example, on some of the large shafts the shop manufactures, operators will manually face off one end and drill a center hole before writing the main program to machine the rest of the part.

Yet, the shop also needed the new lathe to enable operators to program entire jobs via a conversational programming interface. JBC uses GibbsCAM CAD/CAM software for offline programming of its other machines, but Mr. Harvey says that simple, two-axis lathe programming can take longer that way versus programming via the E50’s Siemens 840D CNC with Weiler conversational programming software. This software includes a variety of canned cycles to simplify programing for operations such as longitudinal and transverse machining, radius turning, taper turning, and thread cutting, he says.

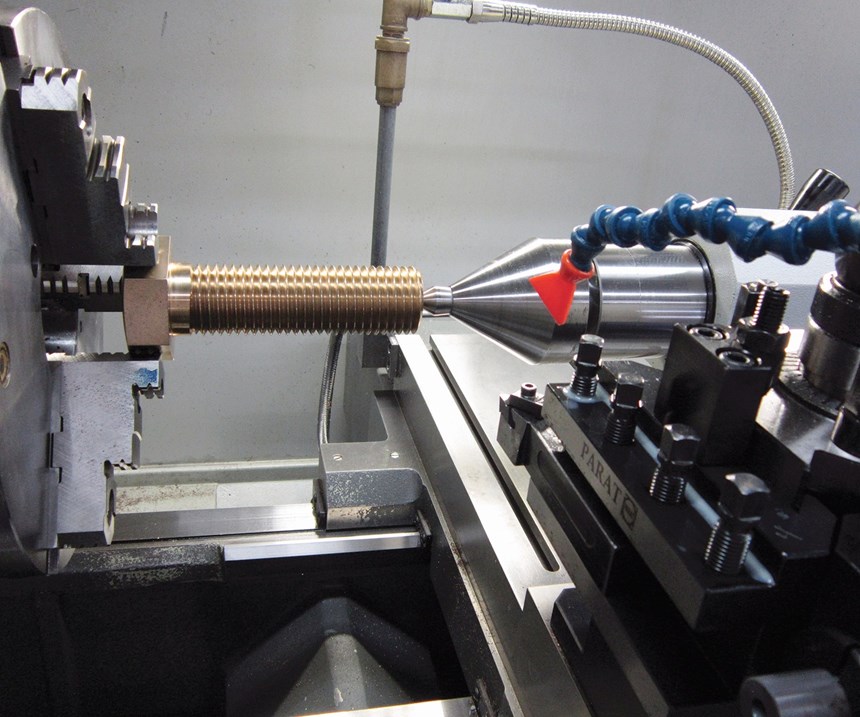

In fact, Mr. Harvey says the shop greatly benefits from the E50’s improved thread cutting capabilities. The old lathe couldn’t quickly pick up a thread, and operators had to guess at positioning the tool by tweaking the offset, sometimes putting blue marking dye on the thread to determine where the tool was positioned by how the dye scratched off the thread. With the E50, an operator can pick up the pitch of a thread in the middle by dialing the tool so that it skins the sides of the thread, then defining the type of thread in the control and “teaching” the machine the position of the thread pitch. Mr. Harvey says the shop often uses this feature for thread repair.

The newer lathe’s thread cycle also enables the operator to create a taper at the end of a thread to create a stronger transition, whereas the previous machine brought the tool straight out of the cut, leaving behind a weak point that could cause threads to break off at the end.

The new lathe also is said to hold tolerances tighter to DIN 8605 standards, and this is especially important for some of JBC’s parts, such as winder mandrels that are used to make cardboard tubes. These mandrels typically are 60 inches long with outer diameters ranging from 1 to 12 inches and a taper of 0.003 inch per foot. Operators use a steady rest and turn this taper in sections, then manually polish so the sections blend together. According to Mr. Harvey, the mandrels that came off the old machine needed a lot of polishing to get an accurate taper, but because the new machine’s tolerances are tighter, polishing either takes less time or no longer is required.

The 2,500-rpm E50 also provides spindle torque of 1,107 foot-pounds, which has enabled JBC to perform heavier cuts, such as drilling with a 2-inch-diameter TungSix-Drill indexable-insert drill from Tungaloy. Before, when machining 6-inch stainless steel hubs, the shop had to first drill the blanks with this indexable-insert drill on a VMC or another lathe, and then send them to the old lathe. Now, everything can be done on one machine, which simplifies job scheduling, Mr. Harvey says.

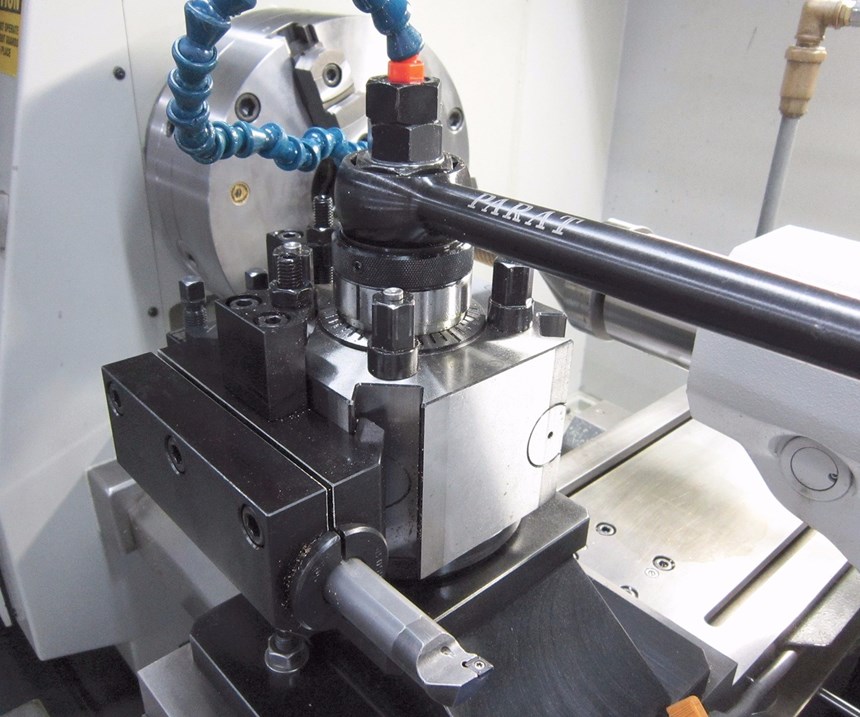

The shop also is reaping benefits from the Parat turret toolpost system that Mr. Weller

recommended for the machine, which features four detents, every 90 degrees, for easy tool positioning. It also features 40 angular location points, at every 9 degrees, for “off-90 degree” tool positioning. (A serrated plate that is screwed down to the cross-slide and the toolpost’s mating serration enables the 9-degree indexing.) Toolpost position repeatability is said to be 0.0002 inch.

Mr. Harvey says JBC also has other ideas for how to take further advantage of the E50’s capabilities, including making use of the machine’s rigidity and 2,248 pounds of Z-axis feed force to try broaching a blind key for an upcoming job.

Related Content

A History of Precision: The Invention and Evolution of Swiss-Style Machining

In the late 1800s, a new technology — Swiss-type machines — emerged to serve Switzerland’s growing watchmaking industry. Today, Swiss-machined parts are ubiquitous, and there’s a good reason for that: No other machining technology can produce tiny, complex components more efficiently or at higher quality.

Read More4 Tips for Staying Profitable in the Face of Change

After more than 40 years in business, this shop has learned how to adapt to stay profitable.

Read MoreOkuma Demonstrates Different Perspectives on Automation

Several machine tools featured at Okuma’s 2023 Technology Showcase included different forms automation, from robots to gantry loaders to pallet changers.

Read MoreSwiss-Type, Live Tooling Lathes Help Turn Company Around

New leadership’s investment in Swiss-type and live tooling lathes has enabled Rathburn Tool & Manufacturing to expand into new markets, reversing the company’s sluggish growth.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)