Shop Thrives on Evolving CAM Capabilities

High speed, turn-mill and “hybrid” tool paths that combine functionality are among the Mastercam CAM software features that help keep this shop competitive.

Share

Tony Johnson, co-owner of United Machine & Metal Fabrication (UMMF), says the success of his business depends on talented people and quality equipment. Unfortunately, good machinists and programmers are “scarce as hens’ teeth,” as he puts it, so it’s equally important to have CAM software that makes programming any part a customer might request as fast and easy as possible. At UMMF, the Mastercam system from CNC Software (Tolland, Connecticut) has filled that role for more than a decade of steady growth. Recent examples of software features that have made a difference at this Conover, North Carolina shop include high speed tool paths, “hybrid” tool paths that combine previously separate functionality, and tool paths designed specifically for multi-axis turn-mills.

UMMF specializes mostly small-volume production of in medium- to large-sized components as well as smaller fabrications for pumps, gearboxes and other equipment common to the mining, defense and other industries. It installed its first seat of Mastercam in 1998. Since then, steady growth has necessitated three separate moves to acquire additional manufacturing space, equipment and staff. What started as a two-employee operation now staffs 18 in a 40,000-square-foot facility. Mr. Johnson runs the shop, while co-owner Amir Rashidi runs the office.

Equipment includes mills, lathes and horizontal boring machines from such builders as Mori Seiki, OKK, Okuma, Doosan and Mazak. To program these machines, the shop uses nine seats of Mastercam X6, including Lathe Level 1, Mill Level 3, Multiaxis and Solids. This version of the software is the latest in a series of releases that have provided UMMF with significant competitive advantages over the years, Mr. Johnson says.

For instance, the software’s high speed tool paths have improved cutting speed, minimized heat generated during machining and reduced tool wear, Mr. Johnson says. One notable example is peel mill, a high speed 2D tool path designed to peel away material layer by layer. According to the developer, it delivers efficient, constant climb milling via trochoidal-type motion with accelerated back-feed moves when the tool is disengaged.

Prior to the release of this tool path, it took UMMF 27 minutes to machine 304 stainless parts that had already been plasma-cut to rough shape. In addition, heat generated during machining tended to cause the material to weld onto the cutter. Since applying peel mill, however, cycle time has dropped to 5 minutes, and inserts last 10 to 15 parts. Essentially, the company is cutting five parts with peel mill for less than the cost of cutting one part previously.

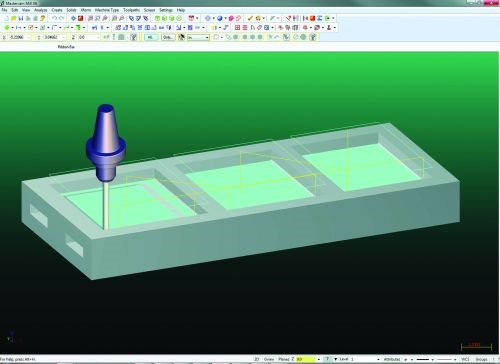

The shop has also benefitted from increasingly sophisticated tool paths that combine different strategies to reduce programming and cycle time. As an example, he cites an aluminum base mold for a carbon fiber chest protector. While simple-looking, this three-cavity mold once took hours to program because its straight sides and contoured floors required different types of tool paths. Recently, however, the use of hybrid tool paths that combine both types of operations cut programming time in half.

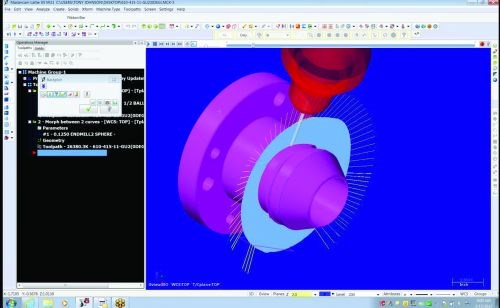

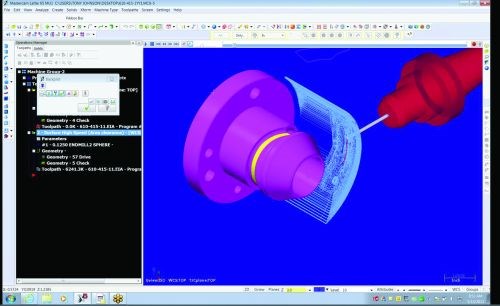

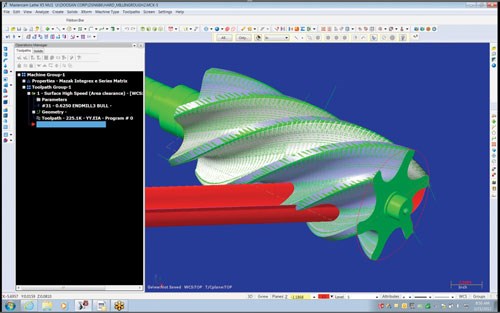

A relatively recent evolution at UMMF is the shop’s increasing reliance on its new Integrex E500H and E410H turn-mill machines from Mazak (Florence, Kentucky). Mastercam supports these machines, both of which can do the work of several mills and lathes, by enabling programmers to create sophisticated mill, multi-axis and lathe tool paths from within a single programming environment, Mr. Johnson says. Multi-operation strategies facilitated by the Integrexes and the Mastercam tool paths that drive them have reduced lead times for complex parts by 50 percent or more in some cases, he reports.

He recalls one highly polished, 5-inch cylindrical extruder equipment part that once took a day and a half to produce. It required operations on three machines: a lathe, a VMC and finally, a rotary indexer to achieve a specific surface patter. Then, it required hours of polishing time to meet the 8-RMS surface finish specification. Recently, however, UMMF completed 12 of these components in less than a week. All roughing operations were conducted on the Integrex E410H using Mastercam’s high speed area clearance tool paths, which use smooth motion to remove bulk material from the inside out. Then, fine rotary fourth-axis moves created a profile with sufficient finish quality to reduce buffing to a fraction of the time it used to take. The total productivity improvement amounted to nearly 200 percent.

Regardless of sophisticated software features or equipment, success still depends in large part on people. For example, services provided by Mastercam reseller Barefoot CNC have been invaluable to getting the most out of the CAM system, Mr. Johnson says. In addition to providing technical support, the reseller consults with UMMF to develop clean posts for new equipment. These posts are critical for the company’s ability to use Mastercam to program the same part for different machines, depending on what is available.

In-house, the shop makes every effort to encourage staff to learn as much as they can and to share that knowledge, Mr. Johnson says. That way, when one programmer encounters a problem, chances are someone else has already figured out how to solve it. Likewise, programmers can cover for each other when someone is away. To maximize the value of their time, programmers typically draw parts, devise manufacturing strategies and assign tool paths for the next part or operation in the queue while simultaneously operating equipment. “Our programmer-machinists are all very good at what they do,” Mr. Johnson says. “We don’t have much downtime.”

Related Content

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreQuick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreInside a CNC-Machined Gothic Monastery in Wyoming

An inside look into the Carmelite Monks of Wyoming, who are combining centuries-old Gothic architectural principles with modern CNC machining to build a monastery in the mountains of Wyoming.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=300;quality=90)