Rob Salesky was fed up. As treasurer at Bayside Machine Corporation, Mr. Salesky knew a thing or two about manufacturing costs, and with years of machining experience under his belt, he also knew a thing or two about downtime. Repeatedly breaking taps had driven both to unacceptable levels.

Bayside needed a reliable, general-purpose tap that would perform well in a variety of applications and materials. After extensive testing, Mr. Salesky found a winner in the MultiTap from Emuge (West Boylston, Massachusetts). Since incorporating the tool into the shop about a year ago, Bayside has saved both time and money while reducing inventory and simplifying tool selection. “Finding a tap that can run in almost everything at a decent cost is great for a shop like us,” Mr. Salesky says. “It offers a great bang for the buck across a variety of applications.”

A closer look at Bayside’s operation makes it easy to see why the company would value such a versatile tool. As Mr. Salesky puts it, the De Pere, Wisconsin-based shop takes on any job that comes through the door. Parts manufactured here run the gamut from open-cavity, 4140 steel molds and stainless steel castings to end hubs for gearbox assembly, stainless steel roto-shredders, coreless winders and knife rolls, among others. The 16,000-square-foot shop’s 38 employees run most of that work on 34 machines, including 13 VMCs, two lathes and six Bridgeports. Materials common among many of the shop’s jobs include 1018, 1020 and 1045 steels; 304 and 316 stainless steels; brass; and aluminum. “We rarely turn down a job,” he says. “From the most basic to the most complex, we do it all.”

That adaptability was a key factor in the company’s ability to sustain itself during the recent recession, Mr. Salesky says. In fact, Bayside was able to continue the 30- to 40-percent annual growth it had experienced since 2003, despite the waning economy. In 2009, it received the Inc. 5000 award for being one of the fastest-growing companies in the United States. Today, the company boasts $4 million in annual sales.

Mr. Salesky attributes this success not only to Bayside’s diverse machining capabilities—the shop even has a large welding department—but also to having the right mix of experience. The business acumen of the men who founded Bayside in 1999, company President Paul Fritsch and Vice President Tracy Burbey, fit well with his own CNC background. (Mr. Salesky became a third partner in 2002.) Along with a skilled, dedicated group of employees, this ensured that Bayside had the knowledge, capability and experience to meet customers’ demands as the market turned. “We were able to give customers the parts they wanted at the price and delivery time they needed,” he says.

However, as customer demands became more urgent, most notably for faster turnarounds, the shop found that its taps could not keep up. The tools were brittle and prone to break during machining, a problem that required interrupting production to burn them out of their holes. The company had determined that using application-specific, specialty taps was not an option. That’s because categorizing all the different tools for the proper application, not to mention deciding which tap to use when, would be both difficult and confusing. Given Bayside’s varied mix of short-run jobs, one general-purpose tap that could perform in a multitude of situations would be the best way to increase productivity and meet demanding delivery schedules, Mr. Salesky says.

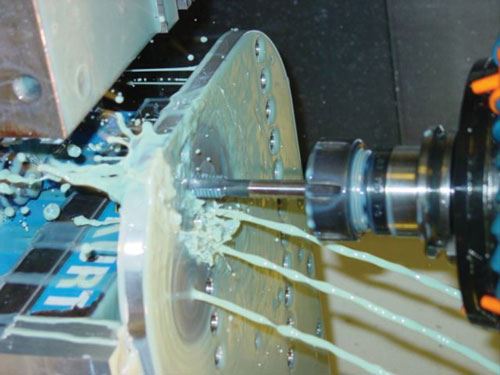

To find the solution, the shop invited six different tap manufacturers to submit two tools each for testing. The number one factor in the company’s purchase decision would be versatility across a wide range of materials. Cost would be the second most important factor. The tap tests were conducted in ½-inch-thick plates of 1018 steel, a material common to many of the shop’s jobs. The challenge: to thread as many of the 100 holes in each plate as possible until the tool failed, the threads trended out of tolerance or the threads tore out.

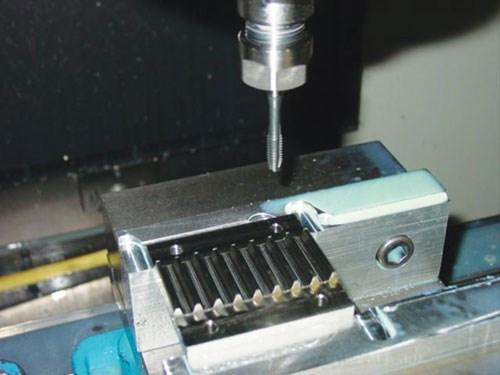

After weeks of intensive testing, Emuge’s MultiTap scored highest in terms of overall performance, life expectancy, availability and delivery. The tool’s DIN-length shank, which provides extra reach, was also an attractive feature for Bayside. After concluding the tap tests, the shop soon replaced its old, broader tap inventory with the MultiTap. Today, the shop stocks about 400 of these tools in both spiral-point and spiral-flute configurations. “We found they are the truest general-purpose tap available,” Mr. Fritsch says.

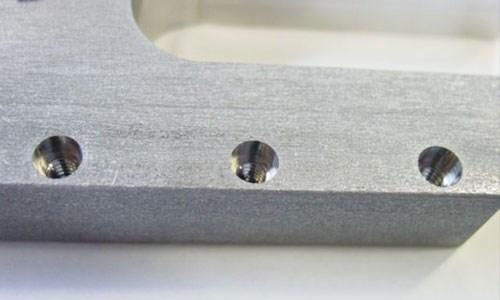

According to Emuge, MultiTap is the result of years of extensive tapping application research. It is constructed of a proprietary grade of high speed steel (HSS-E) that is nitrided with an Ne2 surface treatment and able to withstand twisting and torque, the company says. Along with specialized flute geometry, this base material and surface treatment accounts for much of the tool’s versatility and performance, the manufacturer says. The tap is designed to cut threads to both the common 2B class of fit and the tighter 3B class.

While extolling the virtues of the tool, Mr. Salesky is careful to point out that MultiTap is not a specialty production tap. “It’s not designed to be a luxury sports car; it’s more like a high-quality pickup truck,” he explains. “It does not do what a special application tap would do in a production environment, but it does a great job across a broad spectrum of applications and materials.”

Standardizing on MultiTap has saved Bayside almost 2 percent per month in tooling expenses. This totals almost $20,000 per year in savings. In addition, the shop saves between $20,000 and $25,000 every year by not burning broken taps out of holes or replacing defective parts. Additionally, the company has saved time and money by eliminating the need for operators to determine which tap to use for which job. “We’ve been using MultiTap for about a year now, and they’re still standing up,” Mr. Salesky says. “Believe me, we get rid of tools fast if they don’t work. We have a really rough environment and our machinists want a tool they won’t have to worry about. MultiTap is that tool.”

.jpg;maxWidth=300;quality=90)