Shop Greenery Gives New Meaning to “Plant” Floor

Plants assist with the mood of the shop and quality of the air. Here are a few additional innovations at the shop we covered this month for its application of data-driven manufacturing.

Share

Autodesk, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

L&S Machine in Latrobe, Pennsylvania, has a simple, radical idea for how to use data trends it discovers at the machine tool. Rather than automatically identifying the cause for every trend in on-machine part measurement, rather than creating algorithms for closed-loop process control, this machine shop simply learned to identify which data windows represent a machining process that is on its way toward passing QA inspection. As we describe in an article in MMS’s latest issue, L&S knows which data ranges describe a good day, and just knowing that much is enough. The shop has been able to use this knowledge to successfully prevent machining errors that in the past would have led to scrapped parts.

Touring this shop is fun, because its president Rob DiNardi has put in place other positive innovations as well that are both common-sense and a bit radical at the same time. They include:

Plants

Mr. DiNardi says he took this idea from a documentary on Ferrari’s manufacturing operations in Italy. The Ferrari plant has greenery growing in manufacturing. Now, so does L&S—to an extent that is lush and inviting. The plants not only aid visitors’ positive impressions as well as the working environment in the shop, he says, but they are also a functional aid to air quality. Every leaf is slowly drawing in air. Thus, if ever there is too much oil mist in the shop air, one of the early signs is oily leaves.

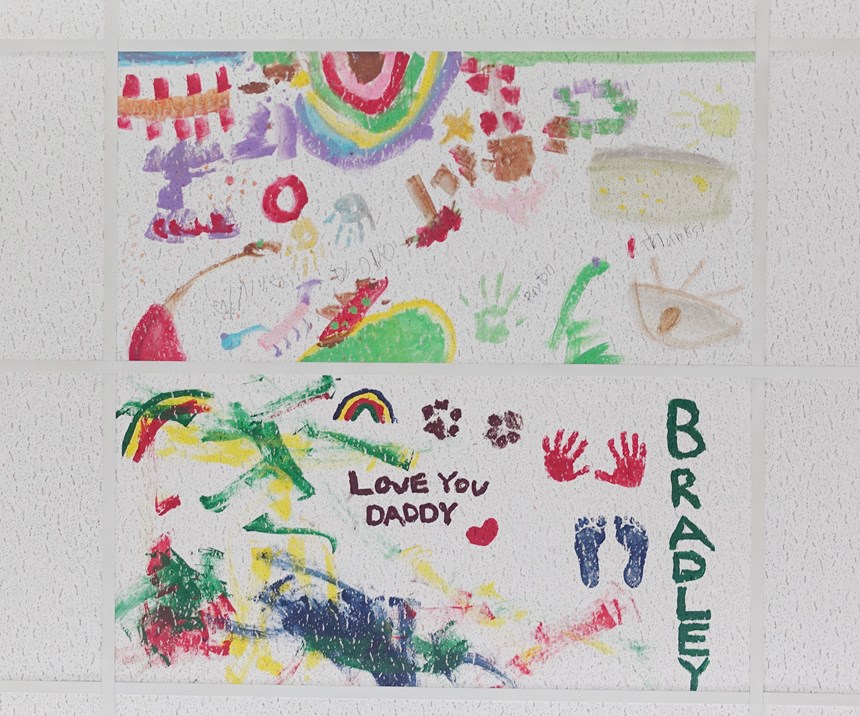

Ceiling Art

People who work at desks have space for reminders of home. Machine-shop employees sometimes have toolboxes they can decorate, but the trend in shops is increasingly toward standard toolkits attached to stations instead of people for the control of inventory. So what is left to personalize? One answer L&S has found is the ceiling overhead. Employees are invited to borrow ceiling tiles in order to personalize them before replacing them above.

Big-Picture View

Even though manufacturing manager Jason Smathers has an office that opens directly onto the machine shop, he also has an array of monitors showing the activity in various parts of the small shop. Of course, he routinely walks the floor to see this same activity directly. But even when his attention is taken with something at his desk, these monitors now make it easy for him to be never from what it happening in the shop, obtaining a comprehensive view with just a glance.

Related Content

-

Can Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

-

Inside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

-

Solve Worker Shortages With ACE Workforce Development

The America’s Cutting Edge (ACE) program is addressing the current shortage in trained and available workers by offering no-cost online and in-person training opportunities in CNC machining and metrology.

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)