Shop Finds Fixturing Solution for Flexing Parts

Precision Grinding and Manufacturing uses an atypical means to fixture thin parts that are prone to flexing when conventional workholding clamps are used: adhesive cured by UV light.

Share

Sometimes, the trickiest aspect of developing an effective machining process is figuring out how best to fixture the part. This can be especially challenging for castings and other workpieces that are relatively thin, because those parts are prone to flexing when conventional mechanical clamps (and even vacuum chucks in some cases) are used. Operators must take care not to distort such parts while tightening clamps, otherwise the parts will spring back to their natural state once the clamps are removed after machining. Vibration can also be an issue for parts like these if they aren’t rigidly fixtured, meaning a quality surface finish might be tough to achieve and cutting parameters might have to be dialed back, extending cycle times. Finding a way to effectively fixture complex, contoured parts can be just as difficult.

Ray Bray says Precision Grinding and Manufacturing (PGM) fought these problems in the past. Mr. Bray is a project engineer for the Rochester, New York, contract shop that specializes in complex, short-run, often repeating work for industries including aerospace, automotive, medical, military, optics, photonics and telecommunications. He says PGM has employed a variety of unconventional methods to more effectively secure relatively thin workpieces for machining over the years, going so far as to use clay, lead and sandbags to supplement conventional mechanical clamps in an effort to minimize vibration.

You won’t find those types of workholding workarounds being applied there today. Instead, the shop uses an advanced, albeit atypical technology that is particularly effective for fixturing flexible parts. In short, this technology uses adhesive to temporarily bond a workpiece to numerous cylindrical grippers installed in a fixture plate. Once the adhesive is cured via ultraviolet (UV) light, the workpiece is securely held at a known datum location in an undistorted, free-state condition. After machining, the adhesive bonds between the grippers and workpiece are easily broken and any excess adhesive is removed from the completed part via a quick, steam-cleaning wash.

Mr. Bray says that while this workholding technique isn’t appropriate for every job that runs through the shop, it has opened opportunities to win work that, in the past, PGM might not have considered bidding on due to the inherent fixturing challenges. It has also enabled PGM to improve existing fixtures the shop uses for jobs that regularly repeat.

Flex-Free Fixturing

William Hockenberger established PGM in 1967. The shop is now led by his son Mike, who is president and CEO. Business has been good over the years, and PGM has recently completed a 20,000-square-foot facility addition, bringing total floor space to 68,000 square feet.

PGM has a wealth of CNC equipment, including machining centers, turning centers and grinding machines. Milling represents the bulk of the work performed there today, for which the shop uses VMCs with four- and five-axis capability as well as HMCs with pallet pools.

William Hockenberger’s son Todd, PGM’s corporate vice president, explains that because a good portion of that milling work involves thin and complex workpieces, the shop has continuously looked for more effective ways to secure those types of parts for machining. A few years ago, PGM learned about photo-activated adhesive workholding (PAAW) technology that was developed at Penn State University, which looked to be well-suited for such troublesome parts. PAAW technology was invented by Professor Edward De Meter, who was awarded two patents covering it. In 2012, Professor De Meter and others formed Blue Photon Technology and Workholding Systems LLC (Whitehall, Michigan) to market the technology to industry end users.

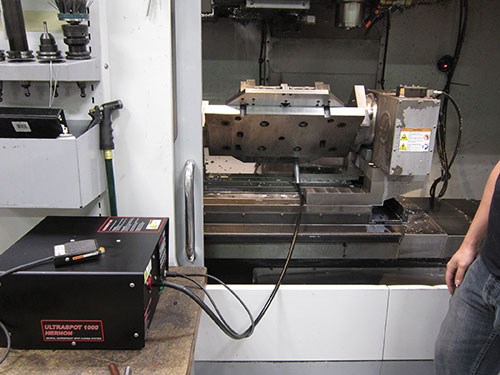

The PAAW workholding technology is effective not only for parts that are prone to flexing when conventional mechanical clamps are used, but also for contoured parts and parts that don’t have convenient locations to accommodate clamps. Its primary components include a 200-watt UV light source with a light guide, a specially developed workholding adhesive and grippers that act as lenses through which the UV light passes to cure the adhesive and bond the part to the fixture.

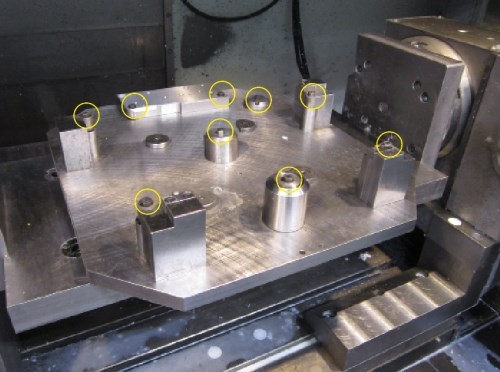

Mr. Bray says the fixture design process using the PAAW system is similar to other more conventional fixtures. In many cases, the shop will create a fixture plate with three hard datum points for a part to rest upon so its location is known in space. (Temporary pins can be used to ensure that the part is installed correctly on the fixture plate.) PAAW grippers are positioned at various locations, and oftentimes a gripper is used at each hard datum point. The number of grippers used largely depends on the size of the part and its geometry. The threaded grippers install in the top of the fixture plate and require a through-hole to enable the UV light to pass up and through the gripper to cure the adhesive.

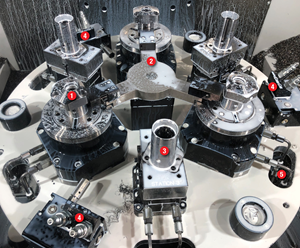

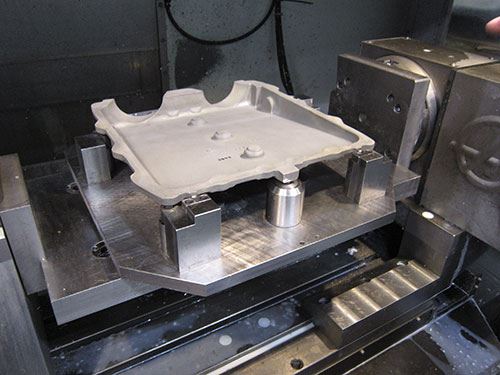

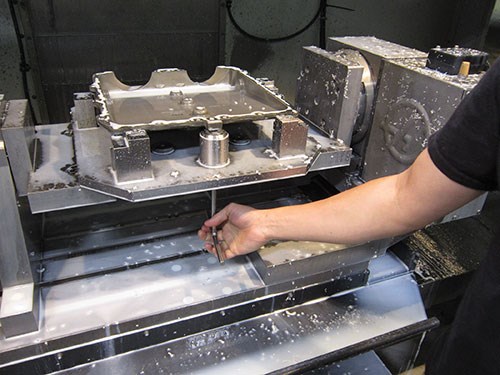

The photos numbered one through four to the left demonstrate the process for fixturing and removing a magnesium casting that PGM machines on a four-axis VMC using the PAAW system. With the fixture plate installed on the machine’s rotary table, operator Alan Jedik dabs the top of each pin with a bit of adhesive. He then installs the casting onto the fixture, which rests on the three hard datum points, and inserts the UV light source’s light guide into each of the three grippers located at those datum points. It typically takes 30 seconds for the UV light to cure the adhesive on each gripper. Mr. Jedik rotates the fixture for easier access to the remaining six grippers and cures the adhesive at each of those points. The part program can begin once the table is rotated back to its proper position.

After machining is completed, a T-handle wrench is used to back off each gripper, twisting the element and shearing the adhesive bond with the workpiece. The workpiece can then be taken off the fixture and a subsequent cleaning operation using a portable steam cleaning device is used to remove any cured adhesive that remains on the workpiece. Adhesive must also be scraped off of the tip of each gripper using a metal scale or straightedge before a subsequent workpiece can be fixtured for machining.

The gaps between the workpiece and grippers (thus, the thickness of the adhesive) can range from 0.010 to 0.125 inch depending on the flatness of the part. The uncured adhesive, which is non-toxic, is sufficiently viscous that it won’t run off grippers regardless of orientation. Axial holding force depends on gripper size and can range from 250 to 800 pounds when using Blue Photon’s BlueGrip S1 adhesive.

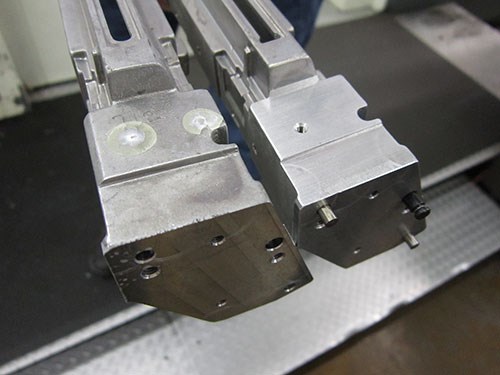

Grippers are made from hardened, corrosion-resistant stainless steel and have a black oxide finish. For repeat jobs, PGM will commonly leave the fixtures intact with the grippers still installed and store them for later use. Otherwise, the grippers can be removed and installed in other fixtures created for new jobs. The latter is most often the case for PGM, because new work continuously flows through the shop.

Another Example

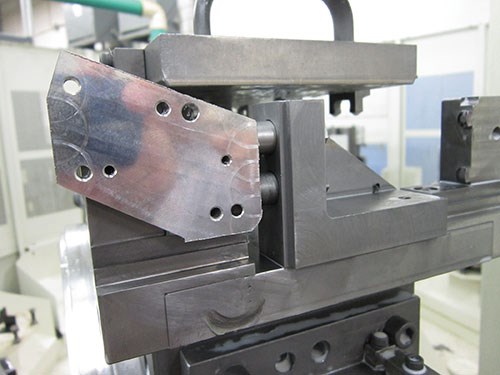

PGM has found that the PAAW system can be used in conjunction with conventional clamps, too, as evidenced with the part shown above for the printing industry. The shop had fixtured this long, relatively skinny part using only mechanical clamps on a tombstone for op. 10 and op. 20 work on one of its pallet-pool HMCs. However, it was challenging and time-consuming for operators to mechanically secure either end of the part without causing it to twist about its longitudinal axis.

Rather than completely revamping the original fixture, Mr. Bray retained the mechanical clamping elements for the middle section of the part, but added two PAAW grippers to either end of the fixture. Operators clamp the middle section of the part as they always have, but use the PAAW system to secure the ends of the part so these ends remain in a free state and there’s no chance of causing the part to twist. After op. 10 work, the part is flipped and refixtured, and an op. 20 milling operation removes whatever cured adhesive remains from the op. 10 fixturing. Therefore, it’s only necessary to steam clean adhesive left behind from the op. 20 fixturing in this case.

Gaining Popularity

Thus far, PGM has used the PAAW system for a couple dozen jobs in materials including aluminum, magnesium and stainless steel. (Blue Photon says the PAAW system can also be used with composites and ceramics.) The shop currently has three portable UV light source units that can easily be transported to machines throughout the shop.

The system will be used to a greater extent for production as well as toolroom work and CMM part inspection as PGM gains more experience with it and experiments with BlueGrip adhesives. Todd Hockenberger says it sometimes serves as a selling point for customers that are either having problems with other part vendors or readily recognize how tough their new design will be to fixture. The shop has a good chance at winning those types of jobs once the customers understand how the system can be applied to their applications. In addition, it can help shorten product design cycles because fixture design is no longer the challenge it once was when mechanical clamps seemingly were the only option. This is big, Mr. Hockenberger says, because PGM tries to get involved as early as possible in each customer’s new product design cycle to offer design for manufacturability (DFM) advice to minimize production time and cost, and get the product to the market faster.

Related Content

Using Jaws as Grippers Enables Flexible, Low-Cost Automation

VersaBuilt’s automation systems significantly boosted Innovative Fabrication’s revenue. In return, the shop has helped VersaBuilt optimize its products.

Read MoreMachining Vektek Hydraulic Swing Clamp Bodies Using Royal Products Collet Fixtures

A study in repeatable and flexible workholding by one OEM for another.

Read MoreNavigating Large-Scale CNC Machining: Suburban Tool’s Niche Strategy to Stay Competitive

Facing increasing competition from lower-cost imports, Suburban Tool made a move toward large-scale, in-house machining. By identifying a niche in large, precision angle plates and tombstones, the company has strengthened its ability to control quality and protect its reputation.

Read MoreFixturing Castings Made Simple Through Adhesive Workholding

When a casting proved too malleable for traditional gripping, Thomas/Euclid Industries adopted — and succeeded with — Blue Photon adhesive workholding.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)