Every once in a while, Jack McGrail will cut a potential customer’s part for free, just to prove a point. These rare occasions usually involve customers who are convinced that the work is best suited for Mr. McGrail’s wire EDM equipment. Typically, their initial skepticism becomes pleasant surprise with the revelation that he can meet required specifications in less time using abrasive waterjet machines from

Omax (Kent, Washington).

Mr. McGrail is president of Jack’s Machine Co., an 11-person job shop in Hanson, Massachusetts that specializes in both waterjet and EDM. The shop got its start in 1985 offering high-volume wire EDM work. The company added its first abrasive waterjet cutting system 10 years later, a move motivated by processing speed. An abrasive waterjet can cut parts that don’t require extremely tight tolerances much faster than wire EDM, Mr. McGrail says.

As accuracies continued to improve, the shop invested in newer machines that enabled moving even more parts from EDM to waterjet. Its current equipment consists of two JetMachining centers from

Omax: the 2652 and the 55100. The cantilever-style 2652, which is the shop’s newest waterjet, features Omax’s Maxjet 5i nozzle, programmable Z-axis movement and a sealed ballscrew drive system. It offers X- and Y-axis cutting travel of 52 by 26 inches and a table size of 69 by 30 inches. The 55100 is a larger cantilever-style machine, sporting a table size of 126 by 65 inches and X- and Y-axis cutting travel of 100 by 55 inches. The cantilever Y axis mounts on a bridge X axis, and the machine features a motorized Z axis. One advantage of this design is that it provides three open sides for material loading, Mr. McGrail notes.

Before purchasing the machines from Brooks Associates in Norwell, Massachusetts, Mr. McGrail presented the distributor with a CAD file for a job the shop had been running on an EDM. With an Omax machine, Brooks technicians cut the part in a little more than a minute, compared to more than 45 minutes on one of the shop’s EDMs. After Mr. McGrail witnessed this, he purchased the machine on the spot, and has been achieving similar processing time reductions ever since.

Key features responsible for these gains include

Omax’s Tilt-A-Jet taper-reduction accessory, IntelliMax control software, a precise motion system, and 30-hp, direct-drive pumps with 55,000-psi cutting capability. These features enable the shop to consistently achieve tolerances of ±0.003 inch, cut square, taper-free edges, and achieve surface finishes as smooth as 64 Ra, Mr. McGrail says.

While the shop’s EDMs can meet tighter tolerances than ±0.003 inch, anything within that range is a potential candidate for faster machining via waterjet. Beyond that, waterjet-cut parts are typically those with straight, vertical cuts, inside cavity radii measuring a minimum of between 0.02 and 0.025 inch, and surface finishes that aren’t extremely critical. Even parts that are processed mostly via EDM often see a waterjet first. Whenever possible, the shop uses waterjet to rough any non-critical features before finish-cutting on wire EDM. This not only significantly shortens processing time, but also conserves wire usage and frees the EDMs for other work.

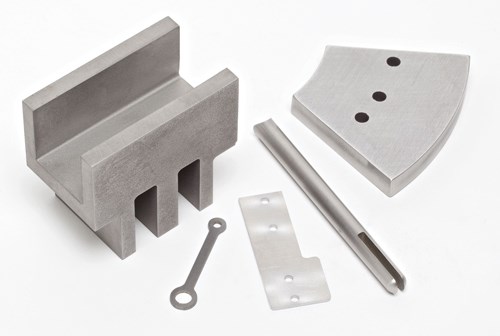

Whether machined on a waterjet or wire EDM, most of the shop’s work starts as 2- by 4-foot and 4- by 8-foot sheets of 410 stainless steel, 300 series stainless steel, 17-4, titanium or aluminum. Some parts are the size of a paperclip, while others require a forklift to move. Thickness typically ranges from 0.03 to 3 inches. Generally, the shop ships between 150 and 200 jobs per month. Volumes range from one-offs to as many as 1,000 parts per order.

When a job comes in, the waterjets’ Intelli-Max control software makes it simple to load a customers’ DXF part file, initiate a tool path and start the cycle within minutes, Mr. McGrail says. Additionally, the control enables operators to draw part files from scratch, if needed. Built-in nesting software helps optimize material usage, and that function can be initiated by simply entering material sheet sizes. This re-duces tasks that would otherwise take hours to only minutes.

Once the cycle starts, the Tilt-A-Jet system ensures accuracy by automatically compensating for the taper that naturally occurs with waterjet cutting. By positioning the cutting head at an angle calculated by the control software, which can range to ±9 degrees, the system transfers the taper to the scrap portion of the raw material. Meanwhile, the machine’s X- and Y-axis movements provide linear positioning repeatability of ±0.002 inch.

Today, approximately 10 percent of work previously processed via wire EDM is now done on waterjet. The shop also has taken on a substantial amount of new work, especially high-production jobs and medical components. Medical jobs are especially suited for waterjet because it does not create heat-affected zones or edge stress, both of which can compromise part integrity. High-production jobs, on the other hand, benefit from the processes’ speed relative to EDM.

Of course, Mr. McGrail emphasizes that waterjet doesn’t replace wire EDM outright. Rather, the processes complement each other. Working with customers to determine the fastest, most efficient and cost-effective way to process parts results in more orders and more repeat customers. And if he needs to, Mr. McGrail says he might just be willing to cut a test part for free to secure that work.

.jpg;maxWidth=300;quality=90)