Scalable Measurement And Quality

Machine shop owners face a fundamental conflict in their efforts to make metrology an integral part of manufacturing processes. On one hand, the critical relationship between quality and profitability makes metalworking professionals reluctant to change tried-and-true methods. On the other hand, however, the drive for better productivity demands that every aspect of the manufacturing process be rationalized and increasingly divorced from the realm of human subjectivity.

Share

Machine shop owners face a fundamental conflict in their efforts to make metrology an integral part of manufacturing processes. On one hand, the critical relationship between quality and profitability makes metalworking professionals reluctant to change tried-and-true methods. This reluctance is reinforced by the fact that the command language for each type of metrology equipment is likely to be unique and based on the proprietary system of a particular manufacturer. Although the emerging DMIS standard was developed to mitigate this problem, the language barrier continues to complicate efforts to integrate measurement into larger networks.

On the other hand, however, the drive for better productivity demands that every aspect of the manufacturing process be rationalized and increasingly divorced from the realm of human subjectivity. While improvements in machine tools have yielded more automated metalworking processes, measurement and quality control continue to represent detours in many manufacturing operations. Although it’s common for the largest manufacturers to use sophisticated quality control based on Statistical Process Control (SPC) systems, smaller manufacturers and job shop owners may perceive this approach as unnecessary or prohibitively expensive.

Siemens Measurement Systems (Spring House, Pennsylvania) addresses these concerns by offering the Criterion SPC Vantage software tool package. The ten component modules of this suite allow users to establish a complete Quality Information System (QIS) that may be networked company-wide. The software’s open architecture and uniform operator interfaces allow data to be accepted from a variety of sources regardless of the particular format. To facilitate international applicability as well, the major components of this program may be operated in English, German, Spanish and French.

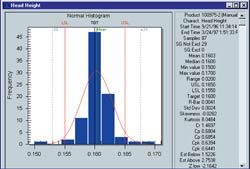

Based on the Windows NT platform, the software is compatible with off-the-shelf PC hardware, third-party measuring devices and CNC controls. The program’s administrative module enables the user to establish classifications and to create data hierarchies for organizing the entire database. A separate data-acquisition module facilitates manual input of information, as well as accepting automatically collected data from predetermined sources. This module automatically categorizes data by product and process, as well as by any number of user-defined tags. It also provides online statistical analysis as data is collected. The software’s analytic module then processes this historical database, creating charts and reports that illustrate quality trends in the ongoing manufacturing process.

The program uses a relational database that can be read by other report writers and query engines. It also generates process capability charts that relate actual output to specific sigma standards. In addition to processing quantitative data, the program also allows inputting qualitative assessments that include non-dimensional measurements such as temperature, pressure, torque and physical attributes.

The Criterion system is scalable for manual, semi-automatic or fully automated operations that comprise various types of measurement devices. This expandable system provides the flexibility to establish a QIS for any size or type of manufacturing operation. The program is designed to integrate numerous types of data into a common system that allows measurement and quality information to be readily accessed and shared throughout a manufacturing organization.

This system provides metalworking professionals with the tools to verify in-process parts and to control the parameters of their manufacturing processes to attain specific quality goals. Assessments of control status and quality trends are made in real time as the data is collected. At regular intervals as desired, a manufacturer may then perform more detailed SPC analysis.

Metalworking professionals who already have begun to integrate measurement and quality functions into their automated processes often discuss the importance of the confidence factor in making this decision. A significant aspect of this confidence consists in the conviction that all components in the manufacturing system will be able to work together. By creating a software package that accommodates a shop’s existing hardware and software systems, Siemens brings sophisticated QIS capability within the reach of many firms.

Related Content

Can ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

Read MoreERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

Read MoreCan AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)