Cycle time and tool life are examples of the kinds of machining process variables that manufacturers often aim to improve. By comparison, energy use typically does not get the same level of attention.

In fact, the energy use of a given machining process is not even likely to be measured or tracked. While power is expensive, it’s not nearly as costly as the machine itself or the tooling consumed in the cut. Plus, choices related to tool path, cutting parameters and so on all directly affect cycle time and tool life. The energy used to remove a given volume of material is much more of an untouchable matter of physics.

Or so it would seem.

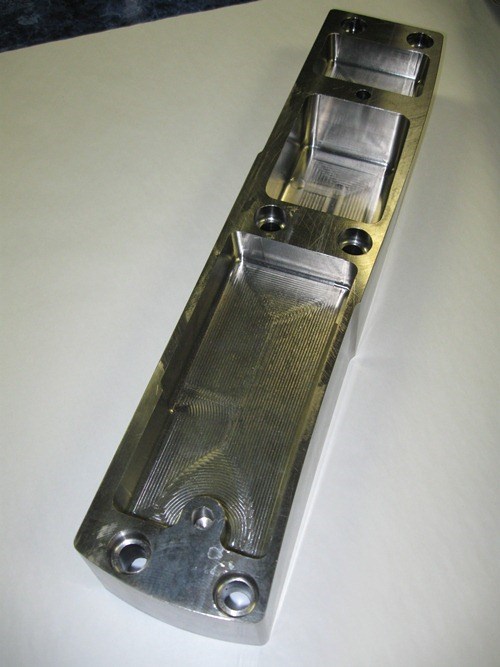

Researchers with GKN Aerospace recently demonstrated something about energy consumption in CNC machining that is very different from this view. Working under the National Center for Defense Manufacturing and Machining as part of the U.S. Air Force’s Sustainable Manufacturing Initiative, GKN found considerable margin for saving energy in the machining process. The company’s aircraft component production plant in Hazelwood, Missouri applied one of its flexible machining cells to this project, which aimed to discover just how much energy could be saved in aircraft part machining. The research focused on a titanium 6Al-4V sample part designed with deep pockets that are typical of defense aircraft components, and it used equipment that is just as typical—namely, horizontal machining centers that had been in service for more than a decade. Using a power meter, researchers measured the effects of various attempts to save energy in this machining application.

What they found is that strategic choices related to tools, coolant, programming and parameters can all combine to reduce the level of energy use by 73 percent of what this plant’s established processes would normally consume.

The findings actually went beyond energy savings. The Air Force funded this study not only to prepare suppliers for potentially higher energy costs in the future, but also to look for manufacturing efficiencies that apply in any scenario. Some of the measures proven in this study save energy specifically because of how well they save cycle time, a valuable improvement on its own.

Principal engineer Cedo Nedic and NC programmer John Shain are two GKN staff members who were involved in the sustainable machining research. What follows is a summary of what they learned, including findings from the study that the plant has already starting to apply in production.

More per Revolution

One of the most basic tool-related variables this project considered was the number of flutes on a carbide end mill. The “6-4” in titanium 6-4 could well refer to the number of flutes GKN used to machine it, because historically this plant has applied a six-flute tool to rough the metal and a four-flute tool to finish it. While larger flute numbers had sometimes proved effective as well, the plant had never before had the opportunity to systematically study the effect of flute quantity. Even so, the relevance of this quantity to energy savings seemed straightforward. With more flutes, less of the tool revolution is “wasted,” because more cutting occurs with each turn of the tool.

Brubaker Tool provided GKN with the end mills it used to study flute quantity (and to study through-tool coolant, discussed below). The researchers confirmed that tools with more flutes do deliver energy savings. These tools permit faster feed rates that shorten cycle times and reduce energy use per part.

Yet there is a point where the flute number is too high. The researchers encountered difficulty with 20-flute tools. Testing revealed rapid tool wear at the upper part of the cutting depth with these cutters—wear that they attributed to chip evacuation problems. Reducing the flute count to 16 seemed to prevent this wear by widening the channel between flutes sufficiently to allow the chips to escape. GKN therefore found 16 flutes to be the most energy-efficient option—if energy efficiency is the only consideration.

Whether the tool is cost-efficient is another matter. Mr. Nedic points out that higher-flute-count tools are more expensive and more difficult to regrind. At the extreme, energy cost savings are not enough to justify the added tool expense. He says a tool with eight flutes offers a better compromise between tool cost and the benefit of high feed rate. Where possible, the Hazelwood plant has increasingly been adopting eight-flute tools.

Coolant Considerations

The effectiveness of through-tool coolant delivery was also tested. Solid end mills using only flood coolant were run against otherwise identical end mills that had been modified (again by Brubaker) to deliver coolant through ports near the tips of all of the flutes. The through-tool delivery method provided measurably superior tool life in multiple ways. Not only did the nominal tool life improve with through-tool coolant, but the wear from flute to flute on the same tool was also more consistent. That consistency effectively extends the tool life advantage, because if a tool can be trusted to wear predictably, then it can be trusted to remain in the cut longer as it wears.

But in this case as well, the cost-effectiveness has to be questioned. Mr. Nedic says the team’s testing of through-tool coolant demonstrated tool-life improvement of as much as 30 percent. That is significant by itself, but small when compared to through-tool coolant’s cost premium of 100 percent more than the price of the unmodified tool. Again, these findings stem only from this one plant’s evaluation of a single process involving a single part number. Based on these findings, though, Mr. Nedic says he is unlikely to recommend through-tool coolant in titanium unless this delivery method helps with a chip-clearance problem. (An exception, he says, Kennametal’s “Beyond Blast,” an inserted milling tool system that uses a special insert design to get coolant very close to the cutting edge. GKN’s study found that Beyond Blast tools permit higher metal removal rates in face milling compared to GKN’s standard processes. The plant has since adopted this tooling into various face milling operations.)

With regard to the coolant itself, one process improvement that showed unequivocal cost savings was coolant recycling. For its sustainability research, the GKN plant connected the machining cell to a coolant recycling system with a Xybex centrifuge from Master Chemical. Mixing recycled coolant with fresh coolant produced no measurable change in cutting performance, but it saved on coolant use considerably. In full production with this cell, GKN estimates that coolant recycling would save $45,000 per year in coolant purchases while cutting water use by 11 percent.

Programming, Step 1

All of the above are hardware changes applied in the cut or at the machine. GKN’s Mr. Shain says a second and equally important area of energy savings comes before machining ever begins, when the cycle is being programmed. The various ways to refine a milling program include changing the shape of the tool paths as well as “optimizing” the parameters by tailoring the feed rate all along these paths. Does either of these approaches reduce energy use?

Mr. Shain says both do, particularly when used together. Employing one software resource for the tool path and another for feed rate optimization produces such dramatic process improvement that he expects to see this sequence become a standard part of the plant’s approach to programming new jobs.

The researchers used VoluMill software from

Celeritive Technologies to obtain more efficient tool paths for pocket milling. Rather than following the shape of the pocket, VoluMill tool paths aim to keep the stress on the tool consistent by avoiding sharp changes in feed direction. Toolpath moves therefore continually curve, bearing no resemblance to the shape of the final feature for most of the machining. The consistency that these tool paths provide potentially makes it safe to raise speed and feed rates much higher than the programmer would risk in a tool path that includes areas of significant stress fluctuation. Because of the way this faster cutting contributes to energy reduction, the test process that consumed 1.18 kilowatt-hours per cubic inch of material removal using GKN’s baseline machining methods consumed just 0.60 kW-hr/in3 once VoluMill was used for programming. Supplementing this gain with higher-flute-count tools, through-tool coolant and coolant recycling brought the energy use down to 0.43 kW-hr/in3.

Mr. Shain says the researchers then looked to feed rate optimization in search of further savings.

Programming, Step 2

The VoluMill software already has this optimization, he says, but running the tool path through dedicated optimization software improved performance further. However, such optimization is often based on the predicted volume of the chip, he says. That volume correlates to cutting force, but it does not determine cutting force precisely.

Software that does predict this force is

Third Wave Systems’ Production Module. This software uses finite element analysis to model the cut. Using Production Module to tailor cutting parameters so that the cutting force would remain steady yielded the final increment of energy savings, Mr. Shain says. The process combining all these improvements consumed 0.32 kW-hr/in3, a 73-percent reduction from the baseline way that Hazelwood routinely machined parts before the sustainability research began.

Now, that baseline isn’t so routine anymore, thanks in part to the advance of the plant’s processes as a result of these findings. Various existing part numbers have been reprogrammed for cycle time savings using VoluMill and Production Module, and new jobs likely will take advantage of these software resources going forward. Using sequential software in this way might seem cumbersome, but Mr. Shain says the extra steps don’t add much time to critical parts that involve significant programming time already. For example, he says using these software tools on a job requiring 100 programmer hours might raise that time to 110 hours. This is nothing, because hours of cycle time savings will be realized each time the part number is run.

Such savings provide for “sustainability” in multiple ways. While the term usually implies lowering energy use, keeping a job commercially sustainable involves holding costs low enough that the part remains in production. These aims are not contradictory. The programming-related findings of the sustainability testing are particularly promising, GKN says—not only for the energy reduction, but also for the cost reduction and increased capacity resulting from cycle time improvements.