Rounding Off the Edges of Quality and Customer Service

Rounding off corners takes little effort, but can make a big difference in ensuring secure gripping and demonstrating attention to detail.

Share

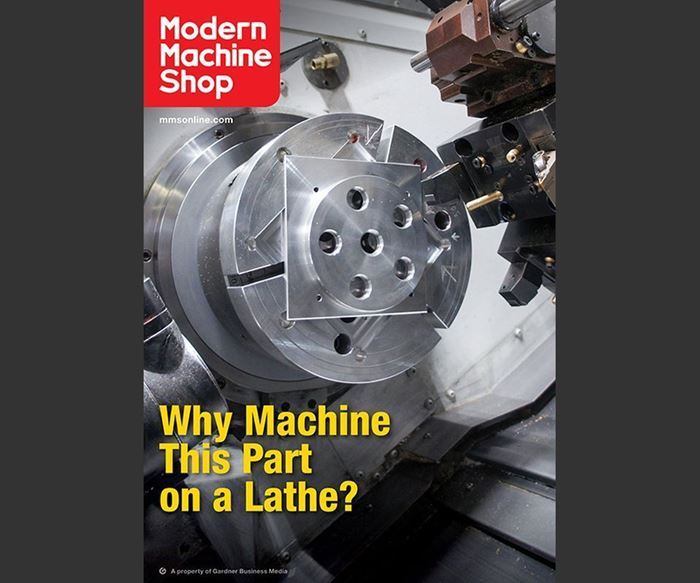

The tagline for our February issue cover, pictured above, asks a good question. After all, the shop that machined this part, South Morgan Technologies, initially intended to do it on a three-axis mill. When that machine was occupied, it moved the part to a subspindle-equipped turning center with Y-axis live tools.

Although this move was unintended, that’s kind of the point, says owner Kevin Ames, who founded the shop in 2011. Ever since then, this shop has thrived on creative application of live-tool turning centers to nimbly flex its capacity and, as he puts it, “say yes to as much work as possible.” One key to that strategy is the use of chuck jaws that can be machined to match virtually any part profile, no matter how boxy. As long as the part has something that can be turned and doesn’t protrude too far from the spindle, these jaws can help make the live-tool turning center a viable alternative to the shop’s most sophisticated VMC, he says.

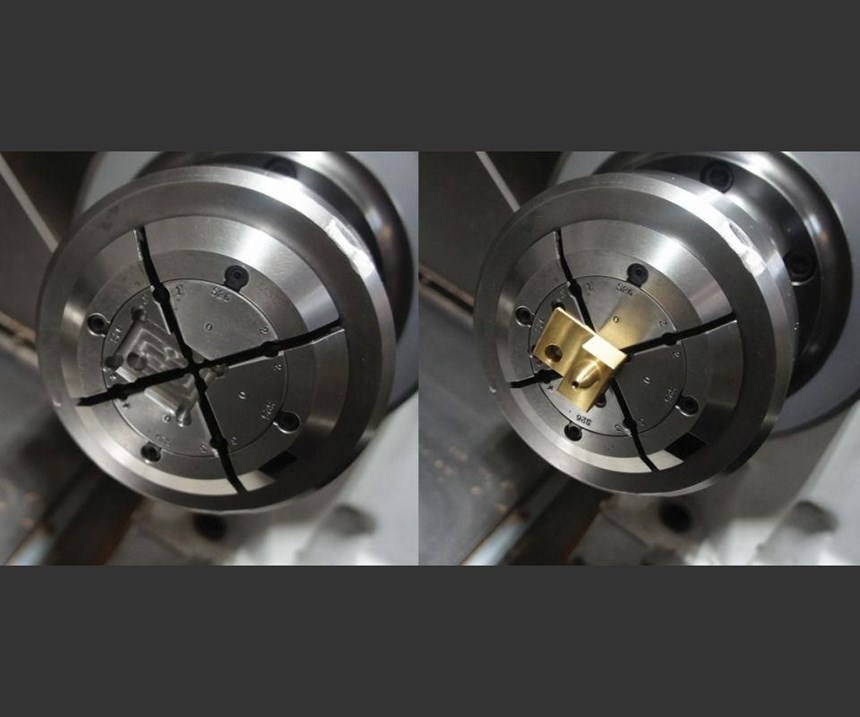

One simple strategy that’s used repeatedly is to drill away the sharp corners in the machined chuck-jaw profile (see the second image above). This simple operation improves gripping security by ensuring two solid points of contact with the either side of each corner of the part. This article offers more detail about how South Morgan makes the most of its live-tool, subspindle turning center.

It’s worth mentioning that machined jaw profile corners aren’t the only sharp edges that South Morgan Technologies removes on a regular basis. Machine shops—particularly small operations—aren’t built only on technology and expertise, but also on relationships. Customer personnel injuring themselves on a shop’s parts might not be the shop’s fault, but it certainly can’t help either. Given that machined metal can be exceedingly sharp, South Morgan technologies has always taken care to eliminate any sharp areas of parts when possible, even if the job doesn’t call for it.

Granted, this isn’t unusual among metalworking businesses, from what I’ve gathered. Nonetheless, in an era when quotes are often won by razor-thin margins, I think it’s worth emphasizing. It also makes me wonder what else shops do to demonstrate their attention to detail. Does your own operation do anything else along these lines, even when jobs don’t require it? If so, I’d love to hear about it.

Related Content

-

A History of Precision: The Invention and Evolution of Swiss-Style Machining

In the late 1800s, a new technology — Swiss-type machines — emerged to serve Switzerland’s growing watchmaking industry. Today, Swiss-machined parts are ubiquitous, and there’s a good reason for that: No other machining technology can produce tiny, complex components more efficiently or at higher quality.

-

Finding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

-

Inverting Turning and Five-Axis Milling at Famar

Automation is only the tip of the iceberg for Famar, which also provides multitasking options for its vertical lathes and horizontal five-axis machine tools.