Reducing the Cost of Water Recycling

This evaporator system is an affordable, yet effective, alternative for manufacturing water reuse and recycling.

Share

Takumi USA

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

Manufacturers need water. However, rising water, energy and waste management prices continue to increase their overall operating costs. Tim Hanna, managing director of PRAB Fluid Filtration, notes that associated regulations are becoming more stringent, too. This is evident with tighter discharge limits imposed by the United States’ National Pollutant Discharge Elimination System (NPDES) program.

These issues have caused manufacturers to consider more affordable, yet effective, alternatives for water reuse and recycling. For example, machine shops are looking more closely at the efficiency of the equipment they use to deal with oily wastewater created by tramp oils in coolant sumps as well as vibratory deburring equipment, floor scrubbers and so on. Recognizing this, PRAB has recently partnered with Veolia Water Solutions and Technologies, an Italian-based manufacturer of water recycling systems, to offer a cost-effective water recycling alternative to the U.S. market: Veolia’s Evaled evaporator system.

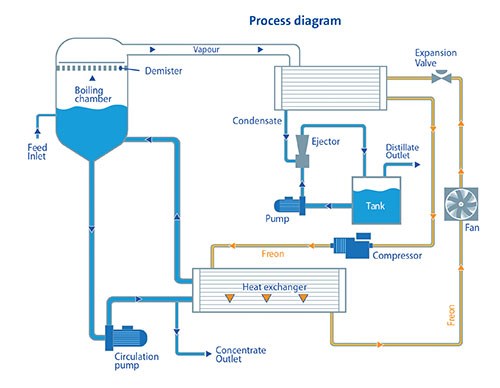

Evaporation is a natural phenomenon recognized as a clean separation technology in the treatment of wastewater, Mr. Hanna explains. However, he says traditional atmospheric evaporators using direct heating methods are inefficient and expensive to operate. Conversely, Evaled evaporators create a vacuum to lower the boiling point of the water. This is a more efficient way to evaporate the wastewater, thus lowering the system’s operating costs. Also, no emissions are discharged into the atmosphere because it is a closed-loop system.

The company offers three primary evaporator systems for industrial applications. The one best-suited for machine shops is the Evaled E-series heat pump model, which uses a heat pump to evaporate particulates from the water. The E-series evaporators create 6 kPa absolute vacuum to save the thermal energy the heat pump produces. This reduces the boiling temperature of the wastewater to approximately 104°F (40°C), and typical conditions such as scaling, precipitation and corrosion that can reduce the system’s performance are said to be eliminated or greatly reduced.

E-series units have a single inlet and two discharge streams for concentrate and distillate. They are skid-mounted for simple installation and use a PLC to enable automatic operation with minimum supervision. They can run 24/7 and require only an electrical supply and compressed air for operation.

Related Content

-

Blaser Swisslube Coolant Minimizes Tool Wear When Machining Titanium

IMTS 2024: Skytec metalworking fluids are well suited for titanium machining because they minimize tool wear and reduce the number of tool changes without compromising process reliability.

-

Managing Coolant with Skimmers, Refractometers and More

Bacteria-infected coolant harms machines and sickens machinists. Coolant management technologies like skimmers and automated systems counter this tendency.

-

New Coolant Designed for Automotive Parts Production

Choosing the right coolant is critical for productivity, economic efficiency and machining quality.

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)