Reducing Setups With Automated Pallet Systems

Wouldn’t it be great to set up a pallet once and then be done with it? Automated pallet systems help companies recover time lost to repeat setups for recurring part orders.

Share

Autodesk, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Every machine shop owner wants repeat business, but setting up a pallet each time a part is ordered can be incredibly time-consuming, eating up hours that could be devoted to more productive pursuits, like cutting chips. Seeking a solution to this dilemma was the primary motivation behind Dane Madsen’s decision to purchase a 40-station automated pallet system two years ago.

“The less time spent on setups, the better,” says the president of West Valley Precision Inc. in San Jose, California. “Now that we can fixture a pallet for machining a particular part and then leave it in place, we’re saving a great deal of time that was formerly spent setting up a pallet whenever we received an order for that part. We get the order, and we’re ready to get started. And if the type of work you’re doing justifies such a system, it doesn’t take long at all to recover your investment in time savings alone.”

Seeking Efficiencies

Since 1987, West Valley Precision has handled both prototyping and production work for industries including aerospace, optics, defense and transportation, also offering engineering and design support to its customers. The company works with metals such as stainless steel, aluminum, high-nickel alloys and titanium, along with plastics including polycarbonate, Teflon and Vespel. Over the years, it has become known for tackling complex projects, such as intricate parts for electron microscopes, so accuracy and repeatability are required. Should a prototype evolve into a production order, an additional quality is highly desirable—the ability to quickly begin work once a repeat order is received.

Ever on the lookout for ways to streamline his company’s operations, Mr. Madsen has long sought out means of achieving this, particularly when it comes to setting up a pallet or handling a part during production. A particular fan of Kitamura equipment due to its rigidity—he now has six five-axis CNC milling machines built by the OEM—early experiments in efficiency involved learning about the benefits of 3+2 machining on a Mytrunnion-5.

“That’s basically where you’re using the slanting and tilting action of the trunnion to perform two of your setups automatically instead of manually,” Mr. Madsen explains. “This method allows you to use shorter tools to avoid chatter, it’s easier to program and it also provides a nice surface finish.”

The success he experienced using this approach led him to begin considering other means of increasing production by minimizing, if not eliminating, setups wherever possible. Thinking of how much time was devoted to fixturing pallets for complex parts that were ordered on a fairly frequent basis—once a month, say—he decided to invest in a Mycenter HX500i, an eight-pallet horizontal milling machine from Kitamura.

Once the machine had been installed, the challenge became figuring out the best way to introduce it into his existing production scheme so that the transition was relatively seamless and didn’t interfere with ongoing jobs and delivery deadlines. He also wanted to begin realizing a return on the capital investment he’d made as soon as possible.

Room to Grow

Since a primary goal was to decrease the time being spent on setups for machining complex parts, Mr. Madsen naturally decided to begin migrating those jobs to his new eight-pallet system first. As he’d hoped, the new approach immediately began having an impact, eliminating repeat setups for recurring part orders once the first setup had been completed. The fixturing was simply left in place on the pallet, and the pallet “dedicated” to that particular part for the duration of the order. Still, there were other considerations to be addressed as well.

“There are two things you need to consider carefully when you’re setting up an automatic pallet system,” Mr. Madsen says. “One is you need to be convinced that the frequency of the orders justifies dedicating a pallet for that particular job, because you don’t want to tear it down once you’ve made that decision.”

Part of this has to do with a customer’s history or with ordering trends that can be identified after a period of time. “We cut some pretty complex parts, so we may only receive orders for 10 or 15 parts at a time,” he says. “But if we see that those orders are being placed every month or two, then we’re happy to set up a pallet for that part and leave the fixtures in place.”

The other involves “spindle time,” he says. In short, it’s important to factor the cycle time a part requires before dedicating a pallet, because if it’s too long, you risk compromising one of the primary benefits of an automated pallet system. “You want the cycle time to be short enough so that you can get the next part under the spindle in a reasonable amount of time,” he says. “Otherwise it doesn’t matter how many preloaded pallets you have, they’re just sitting there waiting for spindle time.”

Once all of these considerations had been addressed, Mr. Madsen found that the new operation ran quite smoothly and that all eight of the pallets on his HX500i had quickly been filled. Convinced that he had the right kind of work to justify an automated pallet system, he decided to bolster the company’s capabilities in 2012 by purchasing a Mycenter-Supercell 400 CNC five-axis machining center with a 40-station pallet changer.

“I figured that we’d already shown that we could fully utilize an eight-pallet system,” he says, “so a larger system would allow us to migrate even more of our complex jobs to dedicated pallets and probably have a few pallets left over to grow with.”

Plenty of Payoffs

Following the same approach he’d developed when introducing the eight-pallet system into his production line, Mr. Madsen quickly began seeing the same improvements he’d witnessed before, only magnified with 40 more pallets now available. As he began assigning his most complex and time-consuming projects to the new pallets, the benefits became even more obvious.

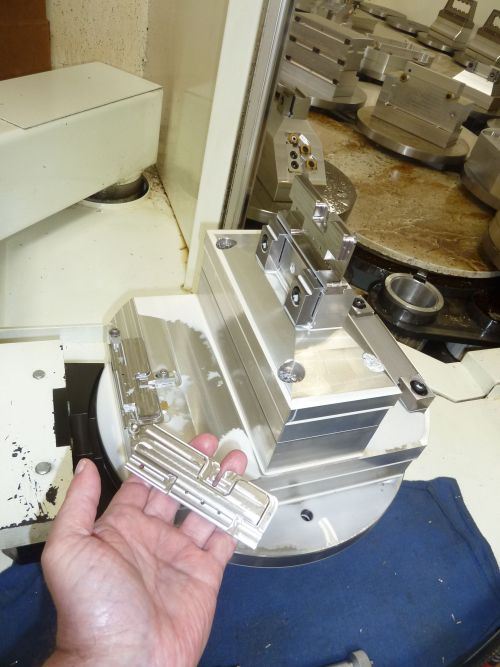

Confident that the Supercell would soon being paying for itself, he experimented with ways that the system could complement and enhance his existing production process. For instance, he discovered that he could create fixturing for three stages of machining a small part on a single pallet. He was first able to load a blank onto one section of the pallet, where it was roughed out before being moved to a second position for additional machining and then finally shifted to the third area of the pallet, which yielded the finished part. While moving the part between positions is still performed manually, the time saved by having this configuration on hand whenever a repeat order is received is substantial.

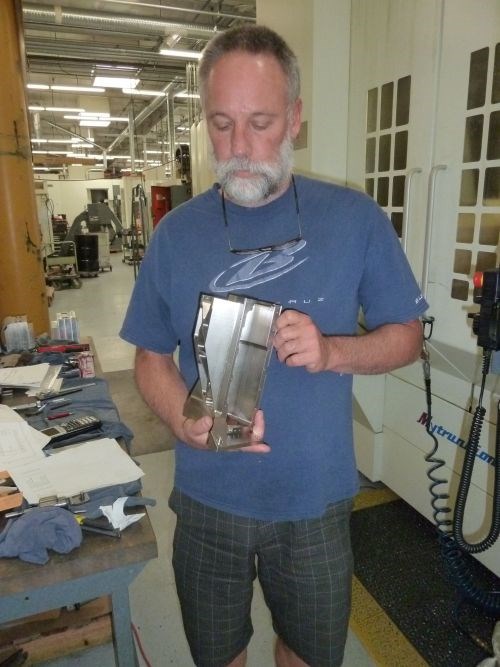

In addition, the machine’s rigidity—made possible by its solid Meehanite cast iron box ways, Mr. Madsen says—prolonged tool life, allowed for rapid material removal and delivered an excellent surface finish right off of the machine. He recalls an early run in which the part would be made of titanium. “We got everything set up and mounted an aluminum blank for a trial run, just to see where we would need to make some adjustments or tighten things up, but there was no need, because that very first test part came off the machine in perfect condition.”

In the two years since the Supercell 400 was installed, 30 pallets have been dedicated to ongoing jobs, with 10 left to grow on. Whether that involves prototypes moving into production, or West Valley Precision entering new markets or expanding on work with existing customers remains to be seen. But Mr. Madsen finds confidence in knowing any challenge that presents itself can be absorbed within this margin for growth.

“To have an automated multi-pallet system on a five-axis machine is just about as good as it gets,” he says. “It will be very interesting to see where new technological developments lead us in the next few years, but for now I’m confident that we can compete with anybody in terms of what we have to offer.”

Lean and Green

His experience in streamlining operations over the past few years has taught Mr. Madsen some important lessons. One has to do with how to best use increased revenue derived by investing in new technologies.

“Remember who bought the machine—you did,” he says. “So reinvest the profits in your company instead of automatically lowering prices, because that way you’ll be around to help your customers continue to grow in the future.”

Another lesson learned involves the benefits of constantly seeking greater efficiencies. “By making these investments, we’re doing better than ever,” Mr. Madsen says. “These days we’re running fewer machines than we had in the past, with fewer operators required to keep them running, and our sales have only continued to rise. So I would consider our automated pallet systems to be investments that not only paid for themselves quickly, but that have also had a major impact on the health of our bottom line moving forward.”

West Valley Precision Inc., call 408-519-5959 or visit wvpi.com. Kitamura, call 847-520-7755 or visit kitamura-machinery.com.

Related Content

Horizontal High-Speed Machining Saves Hundreds of Work Hours

High-speed machining is the latest change at Blair-HSM South, helping this once old-fashioned shop improve productivity and morale while enabling new work.

Read MoreSolar Atmosphere Receives Boeing Approval for Vacuum Oil Quenching

The approval was granted for oil quenching of alloy steels in the company’s new furnace, the Neo.

Read MoreArch Cutting Tools Acquires Custom Carbide Cutter Inc.

The acquisition adds Custom Carbide Cutter’s experience with specialty carbide micro tools and high-performance burrs to Arch Cutting Tool’s portfolio.

Read MoreAFRC, ATI Partner to Boost Aerospace Materials Innovation

ATI Inc. has joined the University of Strathclyde’s AFRC as a tier one member, aiming to develop metallic alloys that support sustainability in the aerospace sector.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)