Moving away from processing parts progressively on multiple mills and lathes in favor of done-in-one production on turn-mill machines has provided all the benefits one might expect at Chicago-area manufacturer Midwest Pressure Systems (MPS). According to the company, excessive part handling is a thing of the past, fewer setups are required, stack-up error is less of a concern, downtime has decreased and throughput has improved. Nonetheless, even a machine capable of churning out a part in one setup typically requires manual intervention to move from one job to another. To ensure those change-overs proceed as efficiently as possible, MPS relies on another solution: quick-change chucks from Kitagawa-Northtech (Schaumburg, Illinois).

A New Beginning

The addition of multi-function machine tools was a significant step for MPS, given the fact that the company didn’t have any machines at all until 2008. In August of that year, owner and founder Bob Vogt decided to bring manufacturing in-house to accommodate rapidly growing business for the company’s core product line: air and gas pressure-boosting systems.

His timing was fortuitous: The owner of a local machine shop that had often contracted with MPS had recently decided to sell his company. Mr. Vogt purchased the shop and moved MPS and its newly acquired machine tools to its current 23,000-square-foot facility in Bensenville, a few miles from Chicago’s O’Hare International Airport. Three full-time operators and one inspector work in the 10,000-square-foot machine shop and adjoining quality control room. The rest of the facility is devoted to office space and areas for pressure-booster assembly and testing.

Under Pressure

The older machining centers and lathes from the machine shop acquisition were sufficient to meet production requirements for nearly two years. However, the company began to struggle in late 2010, when business picked up after a steep decline the previous year. An autumn spike in demand from oil and gas industry customers is typical for MPS, but this time was different, says Mark Traxler, shop manager. The overall industry was in the midst of an upswing, and orders that had been put on hold were coming back online. “We had to figure how to basically triple our production for some of these parts to meet delivery targets,” Mr. Traxler recalls. “A typical part might have to move through two lathe operations and four milling operations, and the whole process was taking entirely too long for us to be able to meet any kind of deadline.”

In addition to creating hours of downtime, the material handling and multiple setups required to move work from machine to machine created scheduling difficulties. That’s because a delay at one workstation would have ripple effects down the line. The multiple-machine production process also increased the risk of stack-up error and associated part defects.

Boosting Capabilities

To consolidate machining operations and get parts out the door faster, Mr. Vogt purchased a Mazak Integrex 200 turn-mill on the recommendation of John Coudal, senior sales associate for Machinery Systems, a local Mazak distributor. The machine proved more than adequate to handle the shop’s production requirements. For most parts, this means meeting tolerances within at least 0.001 inch for select features, typically in 6061 aluminum or 316 stainless steel, Mr. Traxler says. After a year’s worth of steady improvements in setup time, downtime, throughput and scrap rates, the company purchased another Integrex 200, this one with a subspindle.

Together, the two machines now churn out more than half the parts manufactured at MPS. However, Mr. Traxler points out that not all of the benefits of the newly transformed production process can be traced to the machines themselves. Were it not for the QJR series quick-change chucks from Kitagawa-Northtech, operators would have to spend hundreds of additional hours per year on material handling and setups to switch production from job to job.

Amplifying Benefits

MPS purchased its first QJR08 along with its first Integrex after Mr. Coudal suggested the chuck would help maximize the machine’s benefits. Mr. Traxler says the shop’s experience with the chucks proved Mr. Coudal right, and when the company purchased its second Integrex, it opted to equip the main and subspindles with two more of the 8-inch chucks.

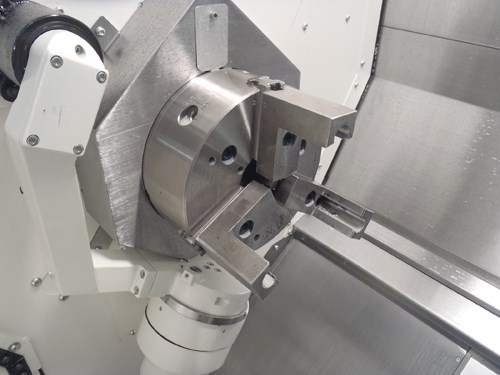

Whereas conventional chuck jaws are typically attached using multiple screws, the QJR system’s jaws slide in and out of a slot in the chuck face and are secured or released by a quarter turn of an accompanying hex key. According to Kitagawa, this enables jaw changes in less than two minutes, compared to 10 minutes or more for conventional chucks. For MPS, this capability is especially useful when customers place rush orders for parts that aren’t normally kept in stock, a relatively common occurrence, Mr. Traxler says. In such cases, the quick-change chucks make it easy to interrupt the production schedule to accommodate a new job without losing an inordinate amount of time reconfiguring one of the turn-mills. “For every part we have to chuck, we’re usually working with a different diameter,” he explains. “The ability to switch back and forth quickly without any hassle is a big deal.”

Still, barring a case like that, jaw changes usually occur only once per week on average. As a result, the actual jaw-change procedure isn’t the chucks’ most time-saving feature, Mr. Traxler points out. He explains that the company uses soft jaws exclusively because they can be machined to match the profile of each workpiece for precise gripping. Each of these dedicated sets of jaws mounts permanently to its own set of base jaws, which, in turn, mate to the chuck face via precision-ground serrations that provide repeatability of 0.0002 inch. With that level of precision, the soft jaws never have to be re-bored, a process that might otherwise take as long as 20 minutes. As a result, the jaws can be stored indefinitely and reused without delay the next time a given job is scheduled. “We just keep them on a shelf and pull them out again when we need them,” Mr. Traxler says. He adds that jaws left over from previous defunct jobs can often be re-machined to fit new parts.

Having a set of dedicated jaws for each part that can be changed easily and don’t require re-boring is especially beneficial because the shop uses the same model chucks on both turn-mills, he says. The only difference is that the second machine’s subspindle uses wrap-around pie jaws to more easily grip workpieces that have had portions of their round surfaces milled away in the main spindle. Regardless, depending on the day’s production schedule, any given part can be produced on either machine by simply moving the chuck jaws from one to another. “We can run a part single-sided in the first machine or run it complete in the second machine with

the same set of jaws,” Mr. Traxler explains. “We just move the jaws around to whichever chuck we need.”

Saving time, Saving money

The ability to swap jaws quickly without reboring saves approximately half an hour to 45 minutes per setup, Mr. Traxler says. Considering a typical MPS setup might take anywhere from 3 to 5 hours, this savings is “quite significant,” he adds. Additionally, the extra time gained from using quick-change chucks is above and beyond the savings provided by moving from a multiple-machine strategy to done-in-one turn-mill production in the first place. Freedom from lengthy setups and additional material handling also provides side benefits. For example, personnel can increase focus on other important areas of the business, such as developing new pressure-booster designs to enhance the product family.

Mr. Traxler sums up the overall benefit of the new process as such: “Before, we could run about 20 or 30 parts at a time. With the Integrexes and quick-change chucks, we can run between 50 and 75 pieces at a time. Even though we are still running relatively low-volume production, we were able to just about triple most of our production runs on our most critical components without the addition of skilled labor. When you compare the cost over time of a new machine tool with tremendous capabilities versus the cost of skilled labor, the savings are quite clear.”

.jpg;maxWidth=300;quality=90)