Having the right tool for an application is always important, but it’s essential when even the slightest cycle time disadvantage can mean the difference between winning and losing an important contract. When Wartburg Tool & Die faced that scenario, it turned to the the Hy-Pro Carb drill from OSG Tap & Die. With a geometry designed to reduce thrust forces and chip size, the tool helped reduce drilling time enough to win the bid.

Established in 1982, Wartburg Tool & Die manufactures replacement and component parts for the medical, robotic and other industries. It operates out of a 15,000-square-foot facility in Wartburg, Tennessee. Most customers are located in Tennessee, Georgia, North Carolina, South Carolina and Ohio.

The job in question involved a production lot of connecting brackets for the company’s largest medical-industry customer. Although Wartburg Tool and Die had done work for this customer for many years, it had not been competitive on higher-quantity production jobs. Securing the order for 1,250 of the brackets, which were constructed of 1008 annealed steel, would require significantly reducing cycle time.

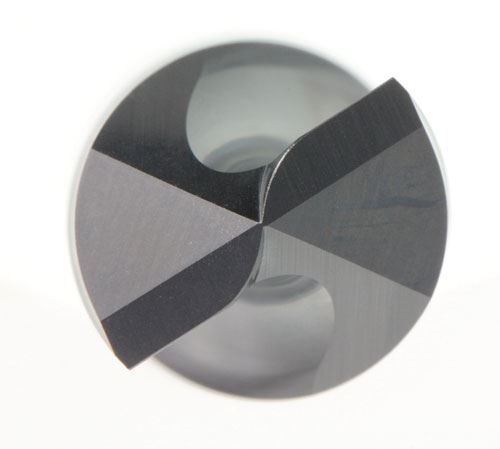

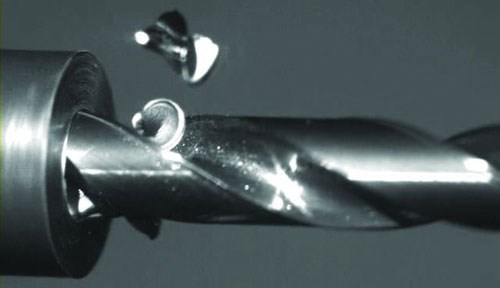

One problem with meeting that goal was efficiently machining the two holes required for each bracket. For help, the shop turned to David Hunter, president of metalworking supplier Tennesee Machine Tool, who recommended OSG’s Hy-Pro Carb drill for the job. Designed to work in a range of materials, the drill features a point and flute geometry designed to reduce thrust forces and chip size. More specifically, a large negative radial rake angle provides a strong cutting edge, while the large lip thickness and wide chip pockets provide stable cutting and improve chip evacuation, says Pete Gennuso, OSG sales engineering supervisor. The drill is also available with coolant-through capabilities to enable higher feed and metal removal rates.

Wartburg Tool and Die ran initial tests at 300 sfm and 0.008 ipr. The drill made it through one part but was not breaking the chips due to the annealed nature of the material. Boosting the feed rate to 0.012 ipr proved successful and enabled the company to drill the hole without pecking. The center drilling operation that they previously employed was also eliminated.

With an increased feed rate and simplified drilling process, the time needed for the drilling operation alone was reduced by 4 minutes and 15 seconds. Combined with other changes to the process, total time savings amounted to 18 minutes and 12 seconds per cycle. According to Wartburg, this per-pert time reduction has generated significant cost savings.

Related Content

-

Moving from cut tapping to form tapping for a notable application cut tooling costs at Siemens Energy and increased tool life a hundredfold.

-

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

-

To cut out laborious manual processes like hand-grinding, this briquette manufacturer revamped its machining and cutting tool arsenal for faster production.

.png;maxWidth=970;quality=90)