Plunge Roughing Right Now

This mold shop makes plunge roughing work using the kind of machine and the kind of tooling it’s been using all along. In other words, this shop achieved a faster metal removal rate just by changing direction.

Share

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

Ask Hilton Tool’s co-owner Tony Vandewalker how the machining process in his shop has changed in the last year or so, and he might begin by pointing to the shop’s newest and fastest machining center. Like many other mold and die makers, this shop in Clackamas, Oregon, has learned—and continues to learn—how to apply light cuts at high feed rates effectively, to bring the part as close as possible to its final form and finish through milling. This shop is getting good at high speed machining.

But that’s not the only way this shop’s process has changed. The high speed machining center does the shop’s finishing work. As for how the roughing process has changed, Mr. Vandewalker would point to an older machining center the shop bought used. On this machine, Hilton Tool realizes a milling technique that represents an even more radical departure from the traditional way the work is done.

The shop has taken rough milling in a whole new direction. Literally.

Plunge roughing is an appropriate name for the method the shop now uses to rough out blocks of H13 or P20 steel for dies and molds. Plunge roughing in general is still uncommon enough, but this shop takes an uncommon approach to it. The shop devised a variation on the technique that involves the use of conventional milling cutters instead of specialized plunging tools. In fact, shop personnel had little success with plunge roughing until they made this tooling switch and made the technique their own.

The fundamental principle behind any plunge roughing process is to remove metal by feeding only in Z, never in X and Y. The tool makes a series of overlapping, drilling-like plunges to remove one cylindrical plug of material after another with each pass. Intuitively this may sound like an inefficient approach, but it’s not. Compared to moves in X and Y, the increased rigidity of a Z-axis move lets the tool attack a larger cross section of material for the same programmed feed rate. That’s why drilling typically achieves a higher metal removal rate than milling. In fact, another name for plunge roughing—at least, plunge roughing the way it’s typically practiced—is “roughing by drilling.” Most practitioners of the technique use a special plunging tool that cuts all along its face, including on the center point.

But Hilton Tool’s variant approach does not use a tool like that. Instead, the shop feeds in Z using a milling cutter that was designed for more conventional machining.

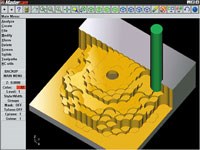

This different style of plunge rougher calls for a different pattern of plunge roughing tool paths. Mr. Vandewalker obtains these using CAM software that offers plunge roughing functionality. This feature automates programming of the standard, more widely used version of the technique, but it doesn’t automatically generate exactly the tool paths Mr. Vandewalker’s own internally developed process requires. He applies the software’s functionality in combination with some of his own manipulation. Thus, his custom technique adds to programming time . . . but that’s likely to change. The software he prefers—Mastercam—may soon be updated to make the extra programming work unnecessary. Its developer, CNC Software, Inc., of Tolland, Connecticut, was quick to see the value of the technique Hilton Tool had developed. Now, CNC Software is working on a revision of the software that will allow this shop and other customers to fully automate programming of this variety of plunge roughing as well.

Even so, the 15 or 20 minutes of extra programming time currently required for a given roughing job is easily justified by the potential payoff. Plunge roughing lets the shop machine away a large volume of material quickly. For example, the shop can rough away between one-third and one-half of the volume of a steel block measuring 12 by 12 by 6 inches in about 20 minutes.

Mr. Vandewalker finds this very appealing. “Roughing is an annoyance,” he says. “It has little to do with what we want out of life.” Getting through the roughing step faster not only lets the shop meet tighter lead time requirements, but it also has the psychological payoff of getting the job more quickly to finishing—that is, to the part of the process where the skill of the people and precision of the equipment more clearly manifest themselves in the final shape of the part.

Changes

That finishing process, too, has changed. Finishing today is performed on a 10,000-rpm Mori Seiki vertical machining center installed earlier this year. The plunge roughing work, by contrast, is performed on an older Matsuura machining center that has been in service much longer.

There is no reason why the shop couldn’t do plunge roughing on the Mori Seiki, except that all of this machine’s time is generally committed to the finishing work that has proven to be the most profitable way to use it. In fact, this work has proven more profitable than the kind of work the shop originally intended for the machine.

The original plan was that the high speed machine would mill EDM electrodes. However, since the day that machine arrived, exactly one electrode has ever been cut on it, Mr. Vandewalker says. That’s because the machine proved so effective at milling the complex forms directly in steel—even heat-treated steel—that the need for EDM has decreased. In place of EDM, the shop now takes advantage of the machine’s accuracy at high feed rates to finish-mill complex die and mold geometries using light cuts taken at rates ranging from 45 ipm (typical) to 200 ipm (rarely). As a result, the machine that was originally intended to make electrodes has instead reduced this shop’s need for electrodes by about 30 percent.

This value realized by questioning assumptions about the “correct” way to use a given piece of equipment likely helped to encourage the shop in its experiments with plunge roughing. The roughing process, too, was reinvented. The difference with roughing, however, is that the machine tool remained the same.

The change was in the way the machine is used, and this changed dramatically. The shop was used to watching the machine move slowly back and forth in the X-Y plane while a cloud of aspirated coolant hung in the air. Now, the machine picks its way from one fast Z-axis move to the next, with no coolant running.

Perhaps the only aspect of the machine’s work that has not changed is the noise. As with traditional roughing, when the plunge roughing job runs, ear plugs are in place.

How The Process Works

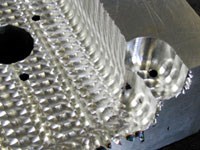

Hilton Tool’s version of plunge roughing uses a three-flute, round-insert milling cutter from Waukesha Cutting Tools (Waukesha, Wisconsin).

This isn’t the type of tool normally used in plunge roughing applications. Plunge roughers are flat-bottomed or nearly flat-bottomed tools that nevertheless cut on the face. They’re like drills without points. And while Hilton did experiment with such a tool initially, the shop had little success. Excessive chatter led to poor tool life. Mr. Vandewalker’s theory is that the small machining center either lacked the rigidity or lacked the power (it’s a 10-hp machine) to use this type of tool effectively. Therefore, instead of cutting on nearly the entire face of the tool, he now plunges with the more conventional tool, and cuts only on the inserts.

The round insert shape makes this easier. A round insert presents the same profile to the part whether work comes at it from the radial or axial direction.

In addition, more inserts seem to be better, Mr. Vandewalker says. He has had some success in recent trials using a cutter with five of these inserts instead of three. Additional flutes let him achieve a higher penetration rate for the same chip load, and therefore even faster metal removal.

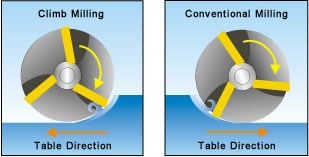

In either case, plunging with a conventional cutter requires non-conventional plunging tool paths. In plunge roughing with a center-cutting tool, for example, the step-over between “holes” can be identical to the step-over between rows of holes. Also, the distinction between “climb” and “conventional” cutting becomes irrelevant. But in Hilton Tool’s version of plunge roughing, both of these conditions are no longer true.

First, the two different step-over increments have to be very different, because the tool can only cut on its inserts. The shop’s increment from one plunge to the next is typically 80 percent of the insert diameter. However, once a row of these plunges has been completed, the step-over to the next row is typically about 80 percent of the tool diameter.

Second, the distinction between climb and conventional cutting is very relevant. A normal plunge roughing process can reduce “air cutting” time by following rows of plunges that alternate direction back and forth across the workpiece. In Hilton Tool’s variety of plunge roughing, that’s not the case. The direction of the tool’s progress down each row is always the same, because this direction is determined by the requirement that the tool must always be climb milling.

Limitations

In addition, Mr. Vandewalker says there are some common applications in which the tool he uses simply can’t take the plunge . . . because to do so would force the tool to cut on its center.

One of these applications is taking the first cut on the inside of a pocket. Such a cut would call for plunging straight into solid material, and the tool can’t do that. Instead, the tool needs to be able to gnaw its way in, cutting only on its inserts the whole time. In other words, it either needs a starter hole, or else needs to be able to violate one of the walls of the pocket by starting its cut on the outer edge of the workpiece.

Another, more subtle case where this technique can’t be used is to machine in the down direction along a sloping form. Plunging to rough uphill is fine, because this makes each plunge shallower than the one that came before it. But plunging downhill would require the tool to take a deeper cut with each successive plunge. A tool that doesn’t cut on its center can’t handle this.

Mr. Vandewalker adds one more observation. This technique doesn’t work well when the plunge meets a pre-existing hole, he says. One example would be a fixturing hole used to clamp the block. Plunging overtop of such a hole leaves the cutter re-cutting chips, which can drastically reduce tool life. For some applications like this one, and the ones cited above, Hilton Tool still uses more conventional roughing techniques.

Different Thinking

But the shop is using those conventional techniques less and less these days. For most of its roughing applications, its own plunge roughing technique is the most effective method the shop has found for achieving a high metal removal rate.

The new technique involves neither a different kind of tool nor a different kind of machine from the ones this shop has used all along. All it took was an open mind. “I have 20 years of machining experience, and I see now I could have done something like this at any time,” Mr. Vandewalker says. That insight only serves to reinforce for him how valuable it is to continually experiment. In search of more payoffs like plunge roughing, he’s determined to keep the willingness to experiment alive in his shop.

Related Content

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreAutomated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read MoreCan ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=150)

.jpg;width=860)