People, Process and Principle: How to Thrive in Adversity

Trinity Precision has found success by sticking to its principles, refining processes and putting people first, even in times of adversity.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

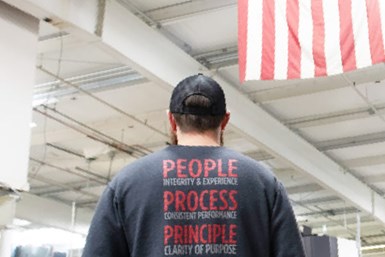

On the shop floor, a Trinity Precision employee proudly sports a tshirt with the shop’s motto.

Visitors to Trinity Precision’s facility are greeted with “People, Process and Principle” on the wall as they enter our building, and for good reason. These three focuses have served us well in both good times and bad. Over the past 18 months, we have worked to continue putting our people first, improving our processes and standing on a firm foundation of principle to guide us. While businesses like ours need to make a profit, there are times when we need to remember the tremendous impact, as employers, that we have on our team. We can’t change everything going on in the world, but we can have an enormous impact on the people we work with and their families. Imagine how many people they impact as well.

When a downturn or disaster happens, it is important for us to stand unshakably on our principles. In the midst of the recent downturn in the aerospace market, we continued to practice our people-first principle. After many companies had already had two or three rounds of lay-offs, we were still able to hold onto our team. Instead of cutting positions right away, we found other ways to reduce costs and rally our company.

Through our “Catch up, Clean up, Rise up” campaign, we refocused our attention in the downturn. During adversity, we found our strength in doing the things we had a difficult time accomplishing when business was booming. Over the past five years, our business has quadrupled. We used the downturn as a time for our team to review our processes and address issues we had in our previous five years while simultaneously preparing for future growth in the next five years. “Prepare for bad times in good and good times in bad,” as my father would always say.

We found that, while we did not have the same frantic pace from work we received during our growth prior to the downturn, we did find a new focus for improving our processes and positioning ourselves to be ready for the next wave of growth. Part of that focus was to ensure that we did things to show the team our commitment to them and their future. These included starting a ramp-up period for matching our 401(k), absorbing all our healthcare cost increases into the company, adding key positions in areas that allow us to onboard new parts faster and focusing on a robotic cell that runs high-mix and low-volume production work.

In addition, we hold a weekly “all hands” meeting for everyone in the company to communicate what is happening within the business. Nature will fill a vacuum, and our imaginations will fill in for facts when people are not told what is happening inside a company. Rarely is the positive imagined. This weekly communication allows us to help our team understand and focus on the realities we are facing. It also discourages the creation of mythical problems that could divert our team’s energy onto the wrong issues to address. At these meetings, we also get insights into our teams’ concerns, and make sure to address them to the best of our ability.

In times of difficulty, we believe there are a couple of key things to put in front of the bottom line that will impact the bottom line in a positive way. Be firmly planted on your principles. Keep your focus on your team so they can keep their focus on the company. The more transparently and frequently managers communicate with their teams, the better the teams can focus on the real issues the company faces.

Prioritizing people, process and principles ensures that, even in adversity, teams will grow stronger and better.

Related Content

DN Solutions Responds to Labor Shortages, Reshoring, the Automotive Industry and More

At its first in-person DIMF since 2019, DN Solutions showcased a range of new technologies, from automation to machine tools to software. President WJ Kim explains how these products are responses to changes within the company and the manufacturing industry as a whole.

Read MoreHow to Pass the Job Interview as an Employer

Job interviews are a two-way street. Follow these tips to make a good impression on your potential future workforce.

Read MoreHow I Made It: Amy Skrzypczak, CNC Machinist, Westminster Tool

At just 28 years old, Amy Skrzypczak is already logging her ninth year as a CNC machinist. While during high school Skrzypczak may not have guessed that she’d soon be running an electrical discharge machining (EDM) department, after attending her local community college she found a home among the “misfits” at Westminster Tool. Today, she oversees the company’s wire EDM operations and feels grateful to have avoided more well-worn career paths.

Read MoreManufacturing Madness: Colleges Vie for Machining Title (Includes Video)

The first annual SEC Machining Competition highlighted students studying for careers in machining, as well as the need to rebuild a domestic manufacturing workforce.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)