News from Horn’s Technology Days

Every two years, cutting tool and carbide specialist Horn invites customers, distributors, suppliers and the industrial press to Tübingen, Germany for its Technology Days event. This year, the highlights include news of expanded production space, plans for a new office building and details of innovative product developments.

Share

Every two years, cutting tool and carbide specialist Horn invites customers, distributors, suppliers and the industrial press to Tübingen, Germany for its Technology Days event. This year, from June 17-19, more than 3,000 guests participated. They had much to learn about because Horn is in a growth mode. Its production facilities and office space are growing. Its product lines are growing. Its workforce is growing. And its technical knowledge base is growing as well.

Here are some of the highlights of the company news revealed at this event.

Twice As Much Production Space

Horn’s third plant in Tübingen will be ready to occupy at the end of 2016.

Horn is adding 12,000 m² of new production in the near vicinity of Tübingen, a university town in the Swabia region of Germany, not far from Stuttgart. By the time it is ready for occupation at the end of 2016, a total of 55 million euros will have been invested in the new site, which is located close to the existing production facilities. This investment represents 30 million euros in the building and 25 million in production technology, which the company says now establishes the state of art in tooling and carbide production.

The two-story production hall will cover a total surface area of 15,000 m². Toolholder production, the coating department and logistics will occupy the additional space when they move into the new building at the end of 2016. The future logistics center will offer three times the capacity of the existing one so that customer delivery can be expedited. The production range currently includes more than 20,000 different types of standard tooling items. On top of that, more than 120,000 customized tooling solutions have been supplied to date. Every year, around 96,000 production orders are processed and approximately nine million inserts are produced in batches of 90 pieces (on average) with a 97 percent degree of automation, the company reports.

About 100 new employees have been added in the last year. In anticipation of the new building’s completion and the extra capacity that it will provide, Horn expects to create additional jobs in the years to come.

New Office Building Announced

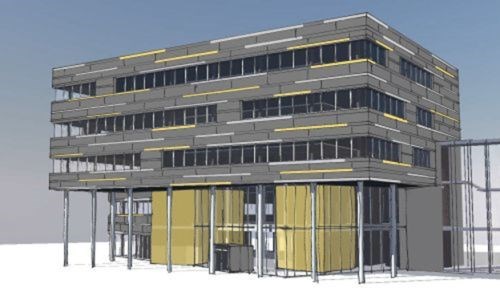

Initial plan for Horn’s new office building.

A new office building will be constructed next to the main factory and existing office building. The design features six levels with a total of 3,500 m² of usable floor space. It will provide offices, meeting rooms and seminar rooms for customer training. Cost of the new office building is estimated at 15 million euros.

Commenting on these plans, managing director Lothar Horn said: "We are investing in our future; our customers especially will see the advantages as we continue to focus on quicker delivery, quality, innovation and precision. So too will our employees, benefiting from a first-class working environment with modern buildings, machinery and equipment.”

Modular Grooving System Expanded

The type 842 cartridges offer a high level of rigidity.

Horn’s range of product offerings is always being renewed and enlarged. The product announcements made during Technology Days were essentially a snapshot of the most significant developments being released at the moment. For example, one of the tooling areas in which Horn has a substantial presence is in modular grooving systems for grooving and parting on lathes and other turning equipment.

Now the company is expanding its grooving system by adding a type 842 cartridge system, which features smaller dimensions for machining smaller workpieces. The system is suitable for parting off various grades of steel and features high rigidity and an efficient cooling concept. The 842 cartridges form part of the 940 modular grooving system, which comprises a basic holder, a grooving tool holder and a cartridge. The key advantages for users lie in the flexible component combinations. The grooving toolholders—which are available in different lengths according to the type of machine and application—are connected to the basic holder.

Specially designed for use on lathes with smaller work areas, the cartridge can be screwed from both sides. The type S100 cutting edge is available with different widths, geometries and coatings to suit the application. The screw clamping device of the cutting edge enables tools to be changed with a high level of repeatable accuracy. The grooving tool features an internal coolant supply with auxiliary coolant flow provided from below and clamping finger coolant flow provided from above. As a result, the jet coolant stream acts directly on the cutting edge for optimum effectiveness, the company says.

Processing Lead-Free Brass

Tools with mono-crystalline diamonds are used for the high polish processing of lead-free brass.

An example of Horn’s technical acumen was apparent in its discussion of new tooling for machining lead-free brass. As background to its tooling developments, the company noted that in order to improve their machinability, copper materials like brass have always been alloyed with lead. However, legislation in many parts of the world points toward a broad prohibition of the use of lead. Unfortunately, dispensing with lead reduces the machinability of these materials. Increased tool wear due to adhesion and material smearing, the formation of long stringy chips, and reductions in process reliability and productivity are the consequence.

For lead-free brass materials, the general rule applies that higher specific cutting forces and tool temperatures are encountered. Heavy material buildup on the chip surface and on the open surface typically results in the tearing out of TiAlN layers in insert coatings. This condition exposes the hard metal substrate. Sharp-edged and coated edges are also subject to types of wear such as micro-chunking caused by the strong tendency toward adhesion of the lead-free copper materials in addition to the aggressive machining forces.

In comparison to TiAlN coatings, company research shows that diamond coatings or diamond cutting segments contribute to a significantly smoother surface, lower frictional forces, a much-reduced tendency toward adhesion and significantly greater heat conductivity. In addition to this, diamond coatings or diamond edges possess exceptionally abrasive wear resistance due to their high degree of hardness, so that they are also ideally suited for dry processing. The cutting speeds obtainable are many times those of TiAlN-coated edges.

Diamond-coated edges and segmented cutting substances like PKD, CVD-diamond and MKD have proven themselves in this application. The latter is unsurpassed for producing highly precise, highly reflective surfaces. Depending upon the copper alloy or type of processing, PKD or CVD-diamond prove to be the cutting substance of choice. The various PKD types are ideal for cutting geometries in custom-ground form tools. CVD-diamond edges offer the highest degree of hardness, and are most suitable for highly sharp cutting and laser-formed chip breakers. These improve chip breakage for dry processing even with a reduced chip thickness, thus producing superior surface finishes and minimal burr formation.

Based on this extensive R & D effort, Horn has responded to the requirements of machining lead-free copper alloys and, with its extensive cutting substance program, offers a variety of customized, safe, productive and economical solutions.

Related Content

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreQuick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreCustom PCD Tools Extend Shop’s Tool Life Upward of Ten Times

Adopting PCD tooling has extended FT Precision’s tool life from days to months — and the test drill is still going strong.

Read MoreBriquetting Manufacturer Tools Up for Faster Turnaround Times

To cut out laborious manual processes like hand-grinding, this briquette manufacturer revamped its machining and cutting tool arsenal for faster production.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.png;maxWidth=300;quality=90)