New Tooling Technologies for Today, Tomorrow

A recent visit to Sandvik Coromant’s headquarters in Sandviken, Sweden, revealed a handful of technologies that will impact machining and machine monitoring moving forward.

Share

I recently visited Sandvik Coromant's headquarters in Sandviken, Sweden, (and insert production facility in nearby Gimo), during a global press event with editors from 20 countries. 2017 marks the 75th anniversary of Sandvik Coromant, so the company wanted to present a few new recent developments in tooling technology, three of which I think I succinctly documented in this tweet I posted at my @MMS_Derek handle during the event:

Learned @SandvikCoromant: tool sensors facilitate #iiot, #additivemanufacturing will change tool mfg., there is a new approach to turning. pic.twitter.com/mKS7Zo9rec

— Derek Korn (@MMS_Derek) March 30, 2017

Two of these I’d call technologies “for the now,” while the other is a technology “for the future.”

Let’s start with one “for the now.” Prime Turning, literally and figuratively, is a genuinely new approach to turning. For essentially, well, ever, turning has been performed with the part rotating and the stationary cutter moving longitudinally down the Z axis (or X and Z axes for profiling) toward the chuck. Then, once that pass was completed, the tool would retract and repeat similar passes. Using appropriate tooling and some new programming techniques, Prime Tooling can perform turning in multiple directions using the same tool: longitudinal turning (toward the chuck or away from it), facing and profiling operations.

Sandvik worked with MasterCAM/CNC Software to develop programming techniques as part of the Prime Turning code generator. On the surface, it might not seem too terribly difficult to simply run the tool in the other direction. However, it did present some programming and tool geometry challenges. In fact, Mark Albert is currently working on a story for our June issue that will provide more detail about all this. For example, it will explain why lower cutting pressure during passes made away from the chuck enables higher cut data and material removal rates during roughing. (This operation creates thinner, wider chips and spreads the load and heat away from the nose radius.) In addition, as cutting is performed in the direction moving away from a shoulder, there is no danger of chip jamming, which is common during conventional longitudinal turning toward the chuck.

While I don’t want to steal his thunder here, this video includes example cuts demonstrating the concept.

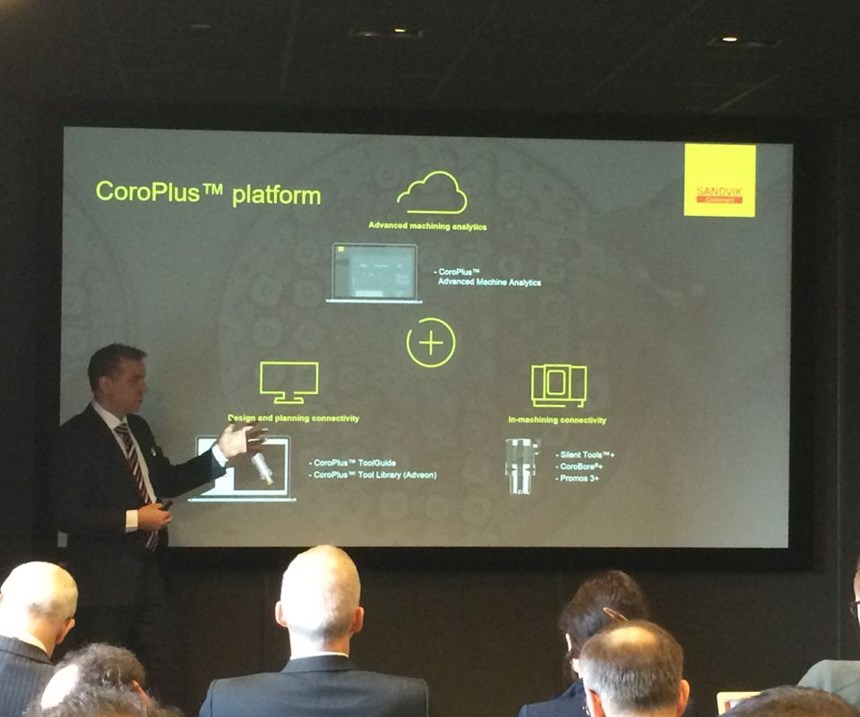

The company has also developed its CoroPlus tool and software platform to facilitate big data/IIoT efforts (you might have learned about these a few months ago at IMTS). One tool example is the CoroBore, which uses an embedded sensor system to enable wireless, automatic fine adjustment of the boring tool’s cutting diameter to speed and simplify setups. Another is the company’s line of Silent Tools, providing in-cut process monitoring and optimization for tools using connected, damped adapters for internal turning of deep features.

In addition, Sandvik’s Promos 3+ data collector monitors tools and operations in real time to help ensure machining safety. Developed by Prometec, Promos 3+ enables on-site or cloud-based monitoring to prevent collisions before they happen, stopping a machine if a tool is missing, breaks or collides with a part or fixture.

Another part of the company’s IIoT offerings is tooling design and planning connectivity with CoroPlus ToolGuide, in which tool and cutting data recommendations can be integrated into the CAD/CAM environment, and ToolLibrary, which is built on the ISO 13399 standard that is open for all cutting tool suppliers.

As for the future, Sandvik is combining its knowledge of additive manufacturing powder metallurgy (through the Sandvik Materials Technology division) and cutting tool design knowledge for AM-grown parts (through the Sandvik Machining Solutions division), bridging these with its new Additive Manufacturing Center. This facility uses powder-bed fusion and binder jetting equipment to develop appropriate AM processes to create functional metal parts and explore new concepts in cutting tools.

For example, the AM-grown end mill body shown in one of the photos above is 60 percent lighter than the same design machined via conventional means. One benefit is lighter weight can facilitate higher spindle speeds. The company says testing of some AM-grown tool designs like this one is currently underway, and it hopes to provide test data/details soon (stay tuned).

All of these new tooling developments demonstrate how the company is leveraging its machining and manufacturing experience and knowledge with an eye toward developing new advances in the future. In fact, Sandvik continues to introduce an average of six new tool designs each day. Many of these developments also serve as an example of how the increasing integration of new software technology, as shown with those used for the Prime Turning and CoroPlus platforms, will continue to impact how shops approach machining in the coming years.

Related Content

Sandvik Cormant's End Mills Eliminate Machining Chatter

The company’s CoroMill Dura line of solid end mills has been extended with aluminum-specific tools.

Read MoreNidec Universal Head Enables Versatile Machining

The compact universal head enables better accessibility between the tool and the workpiece, as well as improved surface-finish quality, greater motion range and high-efficiency machining under ideal machining conditions.

Read MoreKennametal's Expanded Tooling Portfolio Improves Performance

The company has launch eight new products that expand on and support existing platforms across multiple applications.

Read MoreThe Impact of Cutting Teeth Spacing on Machining Stability

Many cutter designs are available, and variable teeth spacing (or variable pitch) cutters can be used to influence milling stability. Let’s discuss why teeth spacing affects stability.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More