New Tooling Improves Machining Cell Output

By incorporating advanced tooling from Seco Tools, Thern Inc. was able to increase its machine tool capacity and reduce cutting costs.

Share

To maintain a two-day turnaround for its standard lifting solutions, Winona, Minnesota-based manufacturer Thern Inc. integrated lean production and one-piece-flow manufacturing cells into its production process. However, when the company needed to increase the output of those cells, it turned its attention to tooling. By incorporating advanced tooling solutions from Seco Tools (Troy, Michigan), the company was able to add cell capacity and reduce tooling costs.

Thern is most recognized for manufacturing the winch used to drop the ball in Times Square every New Year’s Eve. Since its founding in 1948 as a producer of basic winches and hoists, the company has expanded both in size and product offerings. Now employing more than 130 people, it manufactures hand-operated winches; electric, air and hydraulic power winches; cranes; and other lifting, pulling and positioning systems. The equipment is used to lift and maneuver loads weighing 200 to 100,000 pounds or more.

Thern’s standard crane and winch production includes cutting raw material and machining components, then assembling, painting and shipping the final product within two days. To facilitate this schedule, the company’s manufacturing cells also must turn parts around in two days because the shop does not inventory large batches of pre-made components.

However, when the company needed to increase the output of its machining cells, the tight production schedule became a limiting factor.

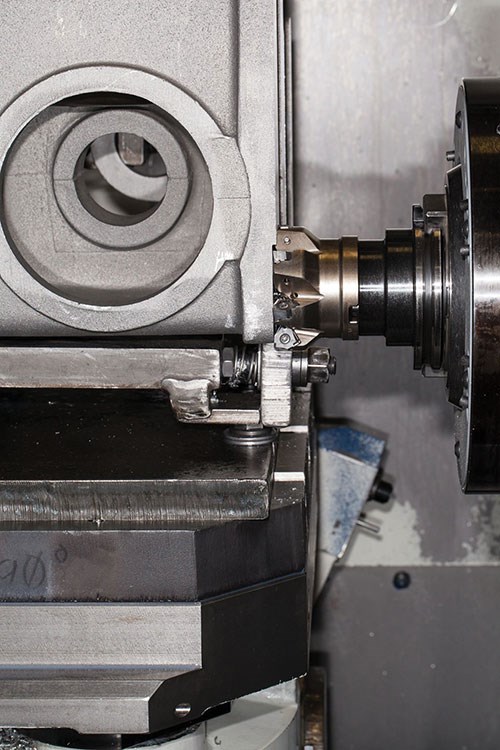

To address this challenge, Thern worked to develop custom setups that allow for quicker change-overs. Likewise, it began working with Seco Tools to evaluate the individual machines that comprise the cells and the parts they produce, looking for ways that new advanced tooling could shorten machining times and create additional cell capacity.

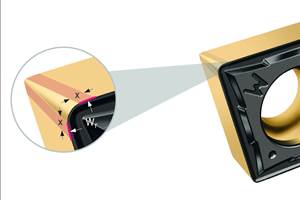

This evaluation led Thern to incorporate a range of Seco tooling including Square 6 face mills in 2-, 3- and 4-inch diameters for cutting a range of materials under a variety of machining conditions; TurboMill 0.625- to 1.5-inch-diameter square shoulder mills for general-purpose applications; and solid carbide drills. The shop also switched to Seco’s turning inserts for their indexable cutter bodies. These inserts include the TP2500 grade, designed for increased speeds and feeds in high-volume and limited production applications; the TP0500 heat-resistant grade, designed for high speed applications as well as long cuts in various types of steel; and TK2001 and TK1002 grades, which reduced the number of grades needed for Thern’s cast iron applications.

During the tooling evaluation, the company estimated that it took several minutes to use a generic solid carbide end mill to helical bore holes in cover components ranging from 1.5 to 2.5 inches in diameter and up to 1.5 inches deep. Thern switched to Seco’s twin bore system, which uses two inserts to increase metal removal. By setting up two of these systems in different holders, the company says it was able to complete holes in seconds.

Another benefit of the new tooling is that the shop can use machining techniques that were impossible with its previous tooling. For instance, Thern is testing Seco’s high-feed cutters, which are designed with a combination of strength and an optimized number of teeth versus diameter to maximize metal removal rates. The close-pitch design enables fast feed rates, and stable cutting performance improves the shop’s operations that require extended-length tooling. One of these applications is machining aluminum gear cases with 8-inch-deep bores. For this operation, the shop was using single-head boring units at low speeds and feeds to prevent chatter. The new high-feed cutter uses circular interpolation, which shaves approximately five minutes from overall part cycle time, says Joe Sheehan, machinist/CNC lead and tooling manager at Thern.

Beyond reducing cycle times, Thern says the new tooling has enhanced the performance of its machine tools, especially the older ones. In the past, the company took heavy cuts at slower speeds, which caused the low-horsepower machines to stall. “Just because a few of our machines aren’t high-horsepower, doesn’t mean we couldn’t improve their performance,” Mr. Sheehan says. Running Seco tooling at shallower depths of cut and increasing turning feed rates by a factor of 10 has cut cycle times from 40 minutes down to 20 or 25 minutes, he says. “For some parts, that means going from 1.5 to 2 or 3 parts per hour—for us, that’s huge.”

For milling operations, Mr. Sheehan says Seco tooling gives the shop the option of running the new cutters at very heavy feed rates and reducing the number of tools per job. In one instance, this cutting technique helped reduce a 33-minute part run time to only three minutes, he says.

The new tooling also makes it possible for Thern to achieve required part surface finishes with less tooling. For example, to maintain surface finish on one part, machinists would have to index inserts after 15 to 20 parts. The inserts were still sharp enough to cut, but unable to maintain the necessary level of surface finish. With Seco’s TP0500 insert grade, the shop says it machines 40 to 60 of these parts before surface finish begins to diminish.

According to Mr. Sheehan, any increased costs associated with incorporating the new tooling have been offset by increases in tool life and process improvements that led to additional cell capacity. For instance, where the shop once used custom tooling, it can now use Seco’s indexable, inserted tooling with the same cutter body for roughing and finishing in different materials. Moreover, after cutter inserts are switched, touch-offs are unnecessary because the inserts repeat within a few thousandths of an inch, he says.

The shop strives to use specific grades and geometries developed for each material it processes. Thern’s machining cells run materials including 1018 and 1045 steel as well as 314 and 17-4 stainless. The company also machines A-36 tubing, and structural steels such as AMS 6378, plate steel, aluminum sand and castings, ductile iron, forged steels, gray cast iron, and powder-coated castings. Separate cutters are set up for each material, and if a tool changer has the capacity, the cutters are stored on the machine to be called up when needed. If a machine lacks the storage capacity, the tools are set aside and manually loaded when needed.

“We rely heavily on Seco to help us match tooling grades and geometries to our materials,” says Brian Bahr, programmer and designer. In the past, he says, the company consumed a lot of tooling due to improper use—using the wrong tool for the job or material. “Seco keeps us aware of the latest tooling developments that should apply to our particular materials to improve our operations. On top of that, they show us the best way to run those tools for optimum performance,” he says.

Seco’s regional application specialist visits Thern weekly to work with the machinists in the cells to further improve machining processes. They discuss current bottlenecks and where tooling changes can improve the situation. Another Seco technical specialist comes in twice a month to train Thern’s machinists.

With the additional cell capacity, the shop can run one shift on several machines. Plus, it can move more work from manual equipment to CNC machines. This additional capacity has also enabled Thern to bring work back in-house. Previously, the shop was running two shifts and still farming out some work.

With the Seco tooling changes already implemented, Mr. Sheehan estimates that Thern has reduced tooling usage by 40 percent, cutting tooling costs by more than $21,000. He also says that the tooling changes boosted cell output by 50 percent or more, amounting to 45 weeks of previously unavailable cell capacity. “And we still have more machines and parts yet to evaluate for potential tooling changes,” he says.

Related Content

Horn Turning Grade Performs in Applications With Variable Hardness

The new SG66 carbide grade is suitable for reliably processing highly temperature-resistant and other difficult-to-machine steel alloys.

Read MoreWalter Turning Grades Feature Curved Wiper Cutting Edge

The FW4 and MW4 positive wiper geometries provide a wiper action that can reportedly be used to reduce machining time by using double the feed rate.

Read MoreTungaloy Grooving Toolholders Provide Highly Stable Machining

TungHeavyGroove includes an enhanced insert clamping design for maximum tool rigidity.

Read MoreSandvik Coromant Parting Tool Provides Improved Surface Quality

CoroCut QD Y-axis parting tools feature upgraded blades with no Y offset, providing easier programming and increased stroke.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=300;quality=90)