New Tech, New Talent at GF Machining

This year’s annual open house marked the debut of not only a new series of wire EDMs, but also an apprenticeship program designed to serve as a pipeline of application and service engineers for years to come.

Share

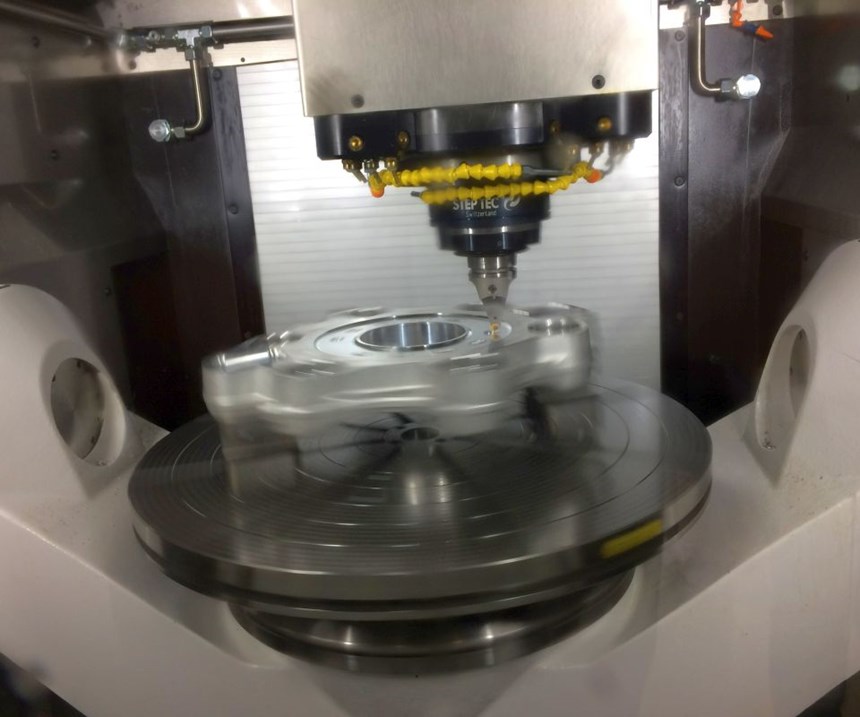

As a young person interested in manufacturing, Corey Ocock potentially has quite a career ahead of him. Speaking to the trade press at GF Machining Solutions’ annual open house event, the company’s first U.S. apprentice expressed fascination with five-axis milling, a technology that’s far removed from what was available in his high school's manufacturing program and even in many businesses. In addition to the latest in milling, his upcoming apprenticeship will expose him to laser-texturing machines and laser-micromachining centers; automation, such as pallet changers and robotics; standardized workholding systems to go along with that automation; and, of course, the technology that proved to be the biggest draw at this year’s open house: electrical discharge machining.

More specifically, the new Cut P series of wire EDMs made its North American debut at the June 6-7 Solution Days event in Lincolnshire, Illinois. However, this wasn’t exactly a debut for everyone in attendance. On-hand to tout the benefits of the new offerings were Brian and Karl Bernt of Extreme Wire EDM, a Grandville, Michigan-based contract provider of wire electrical discharge machining services that was the first manufacturer on the continent to install a Cut P machine. Thanks in part to this purchase, the brothers are projecting significant growth during the next few years.

One of the main reasons for this growth is extra capacity. The 1250 can accommodate parts weighing more than 6 tons and measuring as large as 31.5 inches thick, 90 inches long and 54 inches wide. As detailed in this case study, that’s significantly larger than any of Extreme Wire’s 10 other wire EDMs, and there’s no need for workarounds like removing and reinstalling upper-nozzle components during setup. Extreme Wire also benefits from features common to the entire Cut P line, such as the ability to cut at taper angles ranging to 30 degrees throughout the entirety of Z-axis travel. View the picture gallery above for details, as well as information on the other technologies highlighted at the open house event.

Meanwhile, the spotlight on the new apprenticeship program demonstrated the company’s understanding that shops like Extreme Wire need more than just the right machines. They also need the right people to help maintain and repair those machines when necessary, and to prove that those machines can do what they’re advertised to do before the deal is signed. That’s where apprentices like Mr. Ocock come in. Becoming one of these service or applications engineers takes years of training, all while technology continues to evolve and seasoned personnel continue to retire. A source of fresh talent is critical to future success.

To that end, GF Machining Solutions has partnered with Harper College on a program that has apprentices alternate between class time and real-world, hands-on experience for three years. Upon completion, they receive nationally recognized certifications and an associate degree, and they’ll be expected to fulfill an additional two-year commitment with the company. In addition to qualifications and a job, they’ll have zero college-loan debt, and they’ll have earned a regular salary the whole time, even during periods of only classroom instruction. Set to begin as soon as he graduates high school, Mr. Ocock joins three other students (possibly four) in the company's first class of apprentices.

Related Content

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More