Multitasking CNC Machines Cut Down on Work in Process

This pump manufacturer has integrated flexible multitasking machines and automation to maintain high production levels and flexibility.

Share

Instead of being concerned that CNC multitasking machines might be too cumbersome to set up and too difficult to program, MTH Tool Co. President Tim Tremain recognized their value in his shop’s pump-manufacturing operations. In 1998, the company installed its first multitasking machine tool with a gantry robot, and Mr. Tremain hasn’t looked back as the Plano, Illinois, shop has all but eliminated work in process (WIP), reduced the need for in-process workhandling and significantly increased its output without additional equipment or machining personnel, all while slashing job setup time, improving part tolerances and ensuring process consistency.

Mr. Tremain’s father started the company in 1965 in a garage. Today, MTH specializes in regenerative turbine-style pumps, primarily for feeding hot-water boiler systems, and has come a long way from that garage. “We’re not a job shop. Last year, we generated about 140,000 machined pump parts,” he says. “About seven years prior to that, our production was only 70,000, and that increased output correlates directly with our switch to multitasking technology.”

Pumping Iron (and Bronze and Stainless Steel)

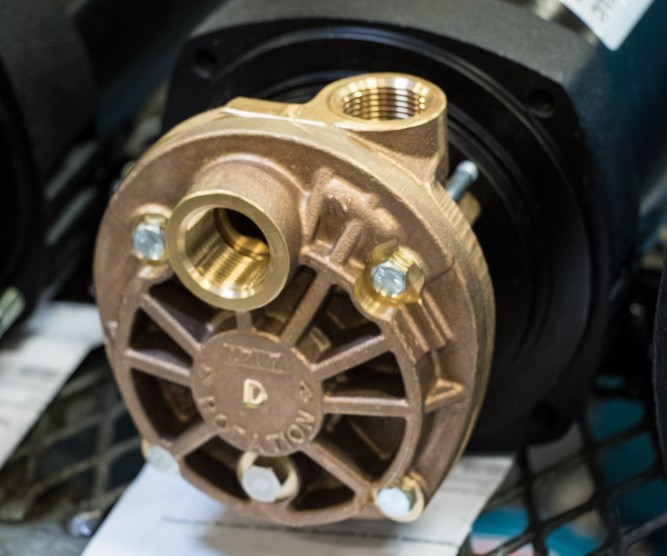

On average, each pump requires around five machined components that primarily include motor brackets, impellers and covers. Additionally, pumps are available in multiple-stage versions that, with every additional stage, generate higher pressures. Workpiece materials are usually cast iron, bronze or 316 stainless steel, with diameters ranging from 2.5 to 14 inches. Tolerances for pump parts and components are often 0.0005 inch, and according to Mr. Tremain, the shop strives to get even tighter. Customers demand higher-pressure pumps that, in turn, require better leak control through tighter, more precise fits between parts.

Before the multitasking machines, the shop relied on single-process turning machines and six-pallet horizontal machining centers with 120-tool magazines. However, the large number of features in each part demanded multiple setups and machines. This manufacturing strategy resulted in bottlenecks as the parts moved between each single-process machine. According to Mr. Tremain, the shop would have three or four containers of material sitting in limbo between turning and milling operations. The containers took up floor space, and costly delays contributed to frustration in the shop. Determined to reduce the level of WIP, Mr. Tremain researched the usefulness of multitasking machines and ultimately invested in the technology.

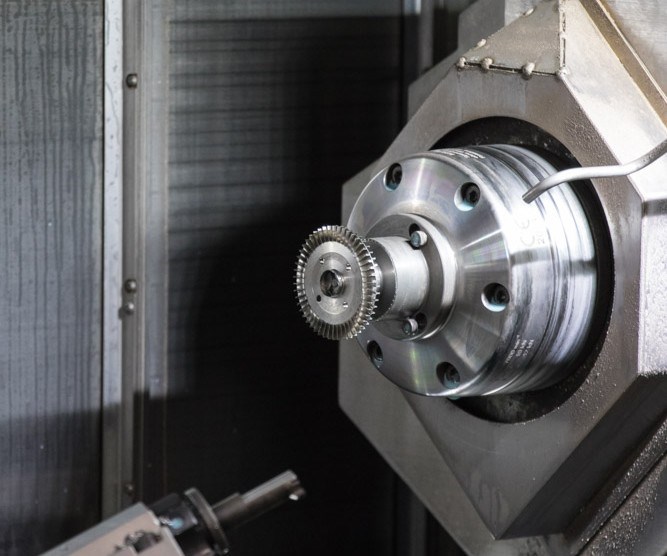

Since then, the company’s machine list has grown to include 12 Mazak Integrex i-series machines in addition to a Quick Turn Smart Nexus 250MSY turning machine with milling capability, a second spindle and a Y axis. Each of the shop’s multitasking machines use gantry-type loaders, a 110- or 120-tool storage magazine, and 1,000-psi high-pressure coolant, along with Tool-Eye and part-inspection probes. Most of the Integrex machines are i-100ST, i-200ST or i-300ST models. In addition to a main turning spindle and tilt milling spindle, these machines feature a second turning spindle and a lower-tool turret with optional live tools.

Mr. Tremain says these features and capabilities are critical to the shop’s continuous and unattended operation, fast job setups and short machine change-over times. Moreover, he says the facility would need to be twice its current size had the company continued with its previous single-process machine strategy. “The output we now accomplish with our 12 Mazaks would have required over 30 individual, single-process machines and the hard-to-find machinists to run them,” Mr. Tremain says. “We could not have grown to our current level of sales and production capacity/output without the multitasking machines.” Now, each machine can complete a part in a single setup, eliminating WIP.

Multitasking Brings Agility, Even in High Production

So-called “done-in-one” capability has enabled the shop to increase output with fewer machines and fewer workers required on any one job. The reduction in machines, in turn, has boosted cost-effectiveness and helped conserve valuable shopfloor space. Because multitasking machines eliminate the need for any in-process work handling, MTH has improved its processing consistency and flexibility as well as in-part concentricity and overall accuracy. In fact, when it comes to improved part accuracy and concentricity, there are some instances in which the shop has experienced five-fold improvements. Concentricity between pump components is critical because all of the parts mount to each other or are stacked together: The more precise each individual component is, the better the pump’s performance.

Most parts require face turning that the shop now does using mill-turn operations on its Mazak multitasking machines. According to Mr. Tremain, doing so is not only faster, but the milling tools last significantly longer than the single-point inserts that would ordinarily be used for turning. “With automation, we quickly found out that the cost of perishable tooling just doesn’t matter anymore. The only thing that counts is keeping the machine running as long as possible, unattended,” he says.

As a selling point for the company’s customers, the flexibility of its multitasking machines enables the shop to produce any one of its parts on multiple machines. When large customers visit a small shop such as MTH, risk management is always a hot topic. “When a half-billion-dollar company walks into your shop intending to have you produce parts for them, they want to know that glitches in your operations will not bring their production lines to a screeching halt,” Mr. Tremain says.

Adding Automation to Multitasking Machining

Multitasking coupled with automation further intensifies the company’s output and production agility. When part demand fluctuates, the Integrex machines enable the shop to easily and quickly switch over from one part to another. “These machines, in my opinion, are made for high-mix, low-volume environments, mainly because the setup times are relatively short” Mr. Tremain says. “We use customized chuck jaws and gantry-robot grippers and plates that accommodate multiple part sizes and types. Tools don’t have to change because we load each machine with all the tools it needs to run all the jobs assigned to it.”

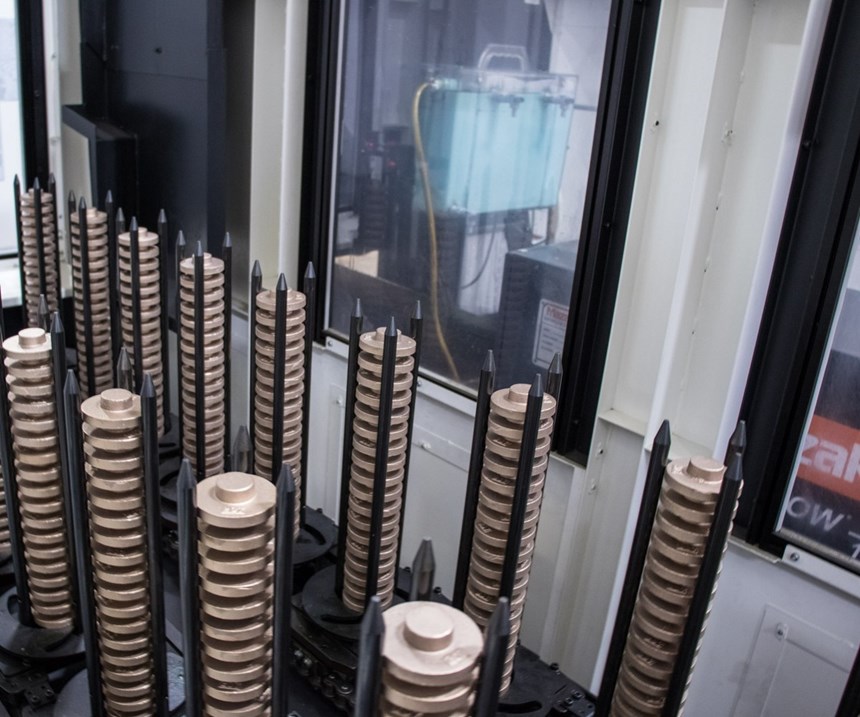

In terms of job lot sizes, the shop tends to issue work orders based on a machine’s automation-loading-table size. Depending on the machine, those capacities can vary from multiples of 48 pieces to multiples of 36, with the median job run size amounting to 72 pieces. In many cases, the shop achieves 24 hours of continuous production from its Integrex multitasking machines, some of which have stacker-style gantries that accommodate as many as 320 of the shop’s pump components at one time. Machinists will start the machines early afternoon on a Friday, and they will run unattended all through the weekend and into Monday before stopping.

Related Content

WFL Milling Machines Feature Smart Sensors, Control System

M50 Millturn / 3,000 mm and M80X Millturn / 4,500 mm turning-boring-milling machines come equipped with a grinding attachment and a vibration-damped Silent ToolsTM Plus boring bar.

Read MoreMachine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreIntegration, Automation and Green Tech Highlight JIMTOF 2022

Known as one of the largest machine tool trade shows in the world, the Japan International Machine Tool Fair (JIMTOF) has a reputation for being a machining technology show more than a machine tool sales event. And this year’s show in Tokyo — the first in-person Japanese machine tool trade show in four years — did not disappoint.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More