Mold Machining On The Move

Rethinking the mold machining process leads to concepts worth considering, even for applications outside mold making.

Share

Few segments of the metalworking industry are as dynamic as mold making, so scanning the horizon for emerging technologies and innovative concepts is a necessary part of staying ahead for any mold shop. Here are a few of the developments likely to create opportunities or set the pace for mold machining.

Side-By-Side Machining

Concept: The core and cavity of a mold are machined side-by-side as left- and right-hand faces from a single workpiece on a multitasking machine.

Background: This concept was demonstrated at IMTS 2004 on an e-series Integrex machining center from Mazak (Florence, Kentucky). Using the flexibility of the tilting milling spindle (B axis) and opposing turning spindles (C axis), the cooling holes were milled on all four side faces and back face of the rectangular workpiece. Core and cavity details were machined while the workpiece was still in one piece. By coordinating the rotation of the turning spindles with the tilting milling spindle, optimum cutter orientation could be achieved for improved surface finish and extended cutter edge life. The workpiece could also be turned over periodically to dump the chips.

The core and cavity portions were then separated, with each segment remaining chucked rigidly in the opposing turning spindles. The two newly exposed sides of the respective pieces were face milled, and cooling holes were drilled to complete both mold halves in a single setup.

This approach greatly reduced the number of setups and operations compared to conventional machining. Accuracy is also enhanced because both mold halves retain perfect orientation to each other until separation.

Enabling Technology: In this application, positioning accuracy in the rotary axes is critical. The multitasking machine uses a roller cam providing 0.0001-degree resolution in the milling spindle. The main and secondary turning spindles also index in 0.0001-degree increments. According to the builder, vibration of the 12,000-rpm milling spindle is 1.5 microns (0.00006 inch). Extremely low spindle vibration protects small-diameter cutting tools in high speed milling applications.

Parallel Machining

Concept: Large mold components are machined in segments on smaller machining centers. The finished segments are then assembled into a complete core or cavity. In some cases, the segments are designed as inserts to fit into pockets in the mold base.

Background: After segmenting a large mold component, each segment may be processed on a smaller machining center, rather than on a larger vertical machine with an extended bed. A smaller horizontal machining center is ideal because it offers advantages in chip evacuation and throughput, although a smaller vertical machine is also applicable.

Because their work envelopes are proportionately smaller, smaller machines are likely to have higher volumetric accuracy. With less mass in the moving axes, smaller machines can achieve higher acceleration and deceleration (acc/dec) rates for contours. Higher acc/dec rates can reduce overall machining time significantly—typically, 20 hours of machining can be completed in 15 hours because of higher acc/dec. On the smaller machines, tool change issues can be managed more readily. For example, it is more likely that one finishing tool can complete finishing operations on its segment of the mold without having to change edges.

Most importantly, two or three machines running simultaneously can outproduce one larger machine. For example, 20 hours of machining can be completed in 7.5 hours on two smaller machines (divide the work time, then factor in the faster acc/dec rates). A group of smaller machines can also be scheduled more flexibly than a single larger machine. Where a large mold can be designed for machining in segments, a mold shop with only smaller machines could still take a job that would otherwise be beyond its capacity.

Moreover, the smaller machines represent a lower capital investment. A mold shop must compare the total cost of two or more smaller machines with the cost of one larger machining center with the combined capacity of the smaller machines.

Finally, a mold designed for parallel machining may represent opportunities for improved maintenance and renewal. For example, it may be possible to section the mold so that areas prone to high wear can be segmented separately. By removing this segment for replacement, repair or restoration, downtime can be held to a minimum.

Enabling Technology: The smaller machines must have extremely high volumetric accuracy so that the assembled mold segments will produce adjoining surfaces that are virtually seamless.

Five-Axis Gundrilling

Concept: The ability to drill water lines at compound angles makes it possible to improve the cooling characteristics of a large mold. Five-axis gundrilling machines make it possible to do this economically by eliminating numerous complex setups.

Background: Molds such as those for car bumper fascia, instrument panels and other plastic parts depend on rapid and efficient cooling to achieve competitive cycle times.

When gundrilling machines with fixed tables and fixed spindles were the rule, mold designers had two options to improve a large mold’s cooling rate. One was to add more straight water lines through the mold blocks. The other was to drill the water lines at compound angles so that the lines ran closer to the surface of the cavity. The first option meant adding significantly to the time spent on gundrilling operations. The second did not necessarily mean longer drilling times, but it added greatly to the setup time because mold pieces had to be manually positioned for each required angle. Setup time for each operation was often much longer than the drilling time.

Neither of these options is very attractive, and they are even less so in the face of demands from customers for lower priced molds.

Five-axis gundrilling machines are proving to be the answer. These machines allow deep holes to be drilled at angles not parallel to the axis of the machine and to do so without special fixtures. This capability greatly reduces the number of setups required to complete a mold. The cavity block of a fascia mold might require as many as 60 setups to drill water lines at compound angles on a fixed-table, fixed-spindle gundrilling machine. A five-axis gundrilling machine does the same work in three or four setups, developers say.

Enabling Technology: The Ixion Auerbach IA TLF-1300.5 five-axis gundrilling machine drew considerable attention at IMTS 2004. This machine featured a programmable rotary table and CNC spindle head that swivels as many as 25 degrees below the normal and 15 degrees above the normal. The machines can be equipped for either conventional gundrilling, STS (single tube system) style drills or both. The latter allows deep drilling at rates as high as 9 inches per minute with a 1-inch diameter tool. According to Barry Speller, president of Ixion Auerbach Inc. in North America (Monroe, New York), the machine’s process control system graphically displays real-time data for oil pressure, oil flow, feed force and torque. This means that drilling can be monitored for optimum drilling rates with less risk of tool breakage. The rigid design of the machine also allows high speed milling, drilling and tapping operations and features an optional tool changer.

Related Content

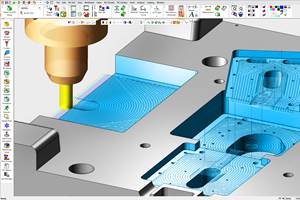

Cimatron's Updated CAD/CAM Software Streamlines Mold Design

Eastec 2023: Cimatron V16 includes a clean new user interface and increased automation for faster mold design, electrode creation and NC programming.

Read MoreIn Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

Read MoreFor This Machine Shop, Licensing Is the Answer to the Inventor’s Dilemma

Machine shops are natural inventors, but not necessarily suited to supporting and marketing a product. This Minnesota shop with an invention related to micromolding will share it through licensing.

Read MoreHow to Achieve Unmatched Accuracy in Very Large Workpieces

Dynamic Tool Corp. purchases two bridge-style double-column CNCs to increase the cutting envelope and maintain 5-micron cutting accuracy in the long term.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)