Micro "Turning" Using Wire EDM

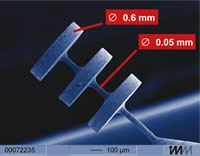

A high speed rotary spindle allows a wire EDM unit to turn round parts with diameters as small as 0.002 inches to a finish of 0.2 Ra while maintaining accurate concentricity.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View MoreIt’s challenging to accurately turn or grind miniature round parts. That’s because the pressure that tools or grinding wheels exert on parts such as the micro electrode on page 56 can cause the parts to deflect, making it difficult to achieve accurate concentricity. In fact, in some cases it’s impossible to machine such tiny parts using these conventional methods.

One alternative is to rotate parts in a spindle mounted on the table of a wire EDM unit and allow the wire to “turn” the parts to shape and size. This is advantageous for micro-machining applications in that material is removed electrically via spark erosion, not mechanically. The chance for deflection is eliminated because workpiece and wire never touch. In addition, the wire EDM unit can be easily programmed to turn contoured round features, whereas grinding operations would require longer setup times and contoured wheels.

Until recently, however, using wire EDM to turn tiny parts presented its own set of challenges, notes Peter Knowles, president of Hirschmann Engineering USA. Mr. Knowles says limitations in machine control, power supply and submerged cutting capability impeded development of an effective micro-turning process using wire EDM. Rotary spindles required for these applications also needed improved speed control and bearing quality to minimize runout.

A joint venture between Hirschmann GmbH and Germany’s Institute for Mikrotechnik Mainz GmbH led to the development of a wire-EDM, micro-turning process based on a new high-speed, rotary spindle design. The resulting Hirschmann H80R.MAC spindle enables wire EDM turning of diameters as small as 0.002 inch to a finish of 0.2 Ra. Another spindle version, the H80R.MNC, combines continuous high-speed rotation with indexing capability.

Housed in stainless steel, the submersible spindle measures 180 by 195 by 98 mm (LWH) and installs on the table of a wire EDM unit. Its variable-speed, AC drive can provide rotational speeds as fast as 1,500 rpm to allow wire-EDM turning of small electrodes; valve slides; medical and micro pump components; and core and ejector pins for micro molds. Final workpiece diameter dictates appropriate spindle speed during the wire EDM operation. High spindle speeds are required when turning very small diameters.

The workpiece clamping system can hold round stock ranging from 1 to 18 mm in diameter. It allows radial and axial runout adjustment to 0.001 mm. Accurate runout helps stabilize the cutting operation and provides precise tolerances. The H80R.MAC version offers three different types of clamping combinations. These include a hard-mounted adjustable clamp and two variations of manual pallet-type clamps that can hold special pallet holders or collets. The H80R.MNC offers those same clamping options, as well as a pneumatic clamp for automatic workpiece loading.

Related Content

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

-

How to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

-

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.