Measurement System Eliminates Shadow-Type Inspection

For Keystone Powdered Metal Co., tooling inspection was time-consuming and not highly repeatable. To solve this problem, the company used Jenoptik's T8000 RC automatic universal roughness and contour measurement system.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View MoreMeasuring and verifying the tooling used to produce precision powdered-metal parts is essential to the manufacturing success of Keystone Powdered Metal Co. of Saint Marys, Pennsylvania. To improve the reliability, repeatability and cost of its tooling inspection, the company turned to the T8000 RC automatic universal roughness and contour measurement system from Jenoptik (Rochester Hills, Michigan). The company installed the system in 2014 and has used it since for production-part justification, and for verifying other types of parts and production tooling.

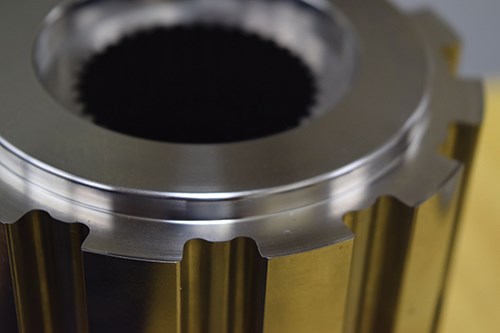

With three facilities approaching a total of 650,000 square feet of manufacturing space, Keystone has the capability to produce virtually any part suitable for powdered metal, including self-lubricating bearings, small structural components, sprockets and gears of varying size and complexity—including high-density, powder-forged helical gears (7.8 grams per cubic centimeter). Large and complex geometries and assemblies consisting of powdered metal parts and non-powdered-metal parts combined also are within the company’s capabilities.

Powdered metal is a technology that helps OEMs in automotive, appliance, outdoor power equipment and electric motor markets improve product quality while lowering cost, the company says. Manufacturing with powdered metal produces net-shape or near-net-shape parts with properties comparable to their wrought equivalents.

Depending on the application and desired final characteristics of the products, Keystone says it optimizes the design, blends the appropriate powder, selects the process to achieve the required properties and specifications, performs all secondary operations, completes any necessary assembly, and completely tests the product.

Historically, Keystone used optical comparators or other shadow-type inspection methods to inspect a casting of the inside surfaces of its tooling. As a casting, the artifact was a mirror image of the actual interior feature of the tooling. It was the only way to “see” the inside contours of the tooling.

Lab personnel would have to cast each part of the tooling and then inspect the surfaces, form and dimensions of the casting with an optical comparator. This caused two major problems. First, the casting material included environmentally unfavorable elements that took extra time to handle and clean up in order to comply with regulations. Also, measuring the tooling details—chamfers, radii, face details, widths and angles—in this way was very time-consuming and not highly repeatable, says Dennis Piccirillo, director of corporate quality assurance.

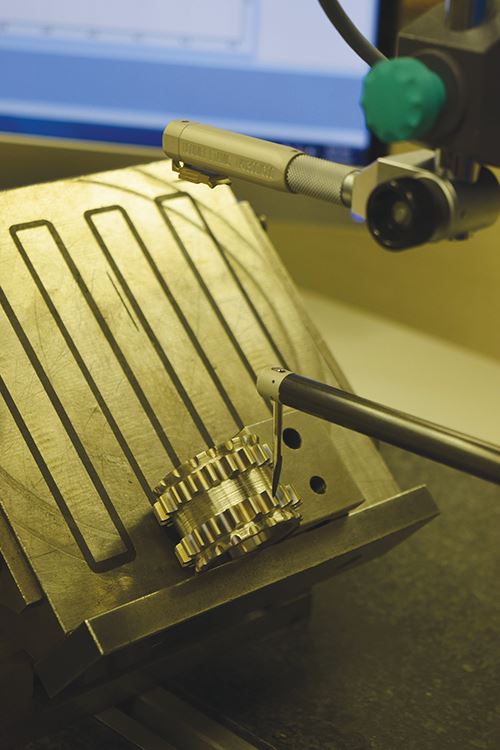

Keystone now uses the Jenoptik contour skidless measuring system to automatically measure inside and outside surfaces of the tooling used to make production powdered-metal automotive engine and transmission parts. The PC-based T8000 RC is designed for demanding contour and roughness measurement either in production or in the measuring room. The modular design permits expansion of measuring station configurations and offers upgrade possibilities for topography and advanced contour measurement. The system provides a traverse length of 120 mm and is well-suited for difficult measurement positions due to the positioning accuracy of the drive bar. Minimum resolution for roughness measurement is 1 or 2 nm and 50 nm for contour.

Before acquiring the Jenoptik system, a particularly difficult feature to measure on one piece of tooling was a small, 15-to-20-degree of arc on an inside radius. “We struggled to get repeatable measurements on this feature,” Mr. Piccirillo says. The company now can accomplish such a small degree of arc very repeatably with the Jenoptik T8000, he says. This eliminates the previous uncertainty Keystone had about the tooling.

“The gage R&R (repeatability and reproducibility) is much more repeatable, and the operators very much appreciate the inspection time savings and the elimination of the casting process,” Mr. Piccirillo says. The measuring station, configured to suit the application at Keystone, can be controlled interactively, and the digital probe ensures a consistently high level of measuring accuracy.

The Wavecontour Digiscan probing system with the T8000 uses intelligent carbide-tipped probe arms with chip-in-arm technology. Probe arms can be changed easily as needed. The contour probing system detects which probe arm is being used and automatically sets the correct measuring conditions. When measuring tasks change, the possibility of operating errors due to incorrect measurement or damage to stylus tips or workpieces is no longer an issue, Keystone says.

Once the measurement is taken, extensive evaluation functions available with the T8000 can output the results in many different parameters, printing them or uploading them to a server.

Keystone says it has greatly reduced quality costs as a result of the T8000 capability. In fact, the company is considering purchasing a duplicate T8000 for its other plants.

Related Content

Turning Fixed-Body Plug Gages Inside Out

Fixed-body mechanical plug gages provide fast, high-performance measurement for tight-tolerance holes.

Read MoreHow to Evaluate Measurement Uncertainty

Manufacturing and measurement are closely coupled. An important consideration for the use of measurement results is the associated measurement uncertainty. This article describes common metrology terms and provides an example uncertainty analysis.

Read MoreBallbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreThe Many Ways of Measuring Thickness

While it may seem to be a straightforward check, there are many approaches to measuring thickness that are determined by the requirements of the part.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)