Manufacturer Automates Quality Control Gaging of Surgical Drills

By replacing manual micrometers with a robotic system, this contract manufacturer reduced manual labor and improved reliable data collection.

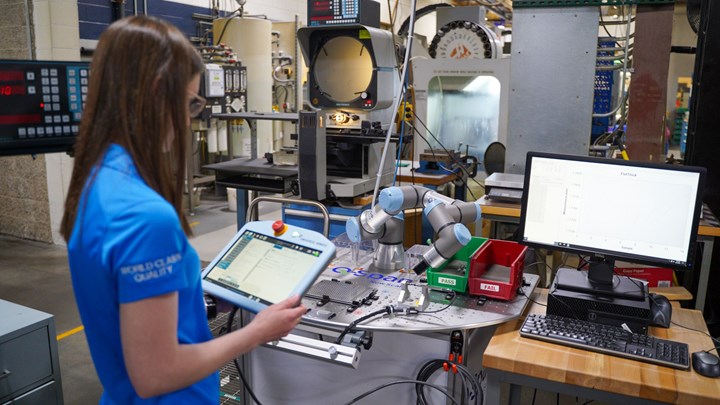

The Q-Span System performing automated QC gauging. The robotic system picks a machined surgical drill from a tray, uses an LVDT gauge to measure several dimensions, records the measurements to a PC, and places the drill in a pass or fail bin. Photo Credit: New Scale Robotics

Medical contract manufacturers must often inspect 100% of their parts, a requirement that makes quality control (QC) by hand extremely inefficient. When Orchid Orthopedic Solutions, a high-mix, high-volume contract manufacturer of precision-machined surgical cutting tools, looked for ways to improve operational efficiency at its facility in Bridgeport, Michigan, quality director Joe Farinella identified the company’s manual gaging process as a prime overhaul candidate.

Farinella implemented New Scale Robotics’ Q-Span Automated Gaging System on Orchid’s line of surgical drills, a change that cut over 50 weekly hours of inspection time. Employees now load the program for the system’s cobot and walk away to perform other high-value tasks during these saved hours.

The time and labor savings not only help cushion inflation’s impact on Orchid, but also help the company cope with the shift toward remote work caused by COVID-19.

“We need creative ways to attract and retain employees in the manufacturing environment, where they’re required to be physically present,” Farinella explains. “One way to do that is through cutting-edge technology that gives them freedom in the workplace to move to areas of need and not be stuck doing repetitive measurement tasks.”

The Q-Span System replaces manual micrometer measurements. The collaborative robot presents workpieces to the LVDT gauge, makes the measurements, and records the data. Photo Credit: New Scale Robotics

The Q-Span System comprises a Universal Robots UR3e collaborative robot, a sturdy mobile workstation table, gripper tools for part handling and software for robot control and data collection. The system can use end-of-arm robotic calipers and work with a variety of existing manual gages in the factory. The workstation tabletop allows for easy change of part trays, bins, conveyors, and reference gages.

Meeting Strict Repeatability and Reproducibility Requirements

To use the Q-Span System, an inspector loads drills into trays, places a tray on the workstation table in a designated location and starts the program. The robot automatically picks each drill from the tray, presents it to a pneumatic drop gage for measurement, uses this measurement data to make a real-time pass/fail decision and places the drill in the appropriate pass or fail bin. The Q-Span System can also wirelessly send the measurement data from the drop gage to a PC for later export to Orchid’s final inspection forms. This eliminates manual data entry mistakes due to operator typos.

Total gage R&R (repeatability and reproducibility) is less than 10%, meeting the parts’ strict quality requirements.

To inspect a new drill part number using the Q-Span System, quality engineer Monica Gonzales edits the control program on a PC and checks it on the robot teach pendant before releasing it to production. Photo Credit: New Scale Robotics

No-Code Programming

The robotic system is validated as a mobile unit, which means inspectors can move it between stations at any time without affecting its validated state. This allows Orchid to optimize the flow to accommodate customer requirements and changes on the manufacturing floor.

The Q-Span software includes a template program for pick-measure-place. This program instructs the cobot to move to a location, use its gripper to pick a drill, move the drill to a gage and then deposit the drill in a pass or fail bin based on the measurement data from the gage.

Quality engineers can edit the template program remotely from a PC or on the floor using the robot teach pendant.

To reprogram the system for a different part number, the engineer enters a few key dimensions of the drill and its tray into a spreadsheet. The spreadsheet calculates suitable waypoint coordinates or points on the cobot’s motion path — which the engineer also enters into the template program before saving the program and sending it remotely to the cobot.

After a visit to production to verify that the program works as it should, the new routine is ready to go. This “no-code” programming feature is suited for high-mix, high-volume manufacturing. Quality engineer Monica Gonzales says that even Orchid’s employees without a background in robotics can use the template to make part-specific programs in about an hour.

Farinella and Gonzales are already eyeing the next opportunity to automate. One idea is to do QC inspection as the parts come off the lathe rather than in lots. For now, though, Orchid can continue enjoying the time savings it has gotten out of the Q-Span System.

Related Content

Made in the USA - Season 1 Episode 2: The Automation Puzzle

There is a fundamental question we need to answer when we talk about automation: To what extent is automation an answer to the skilled workforce shortage, and to what extent is automation vs. Skilled labor the wrong comparison to make in the first place?

Read MoreWhich Approach to Automation Fits Your CNC Machine Tool?

Choosing the right automation to pair with a CNC machine tool cell means weighing various factors, as this fabrication business has learned well.

Read More3 Ways Artificial Intelligence Will Revolutionize Machine Shops

AI will become a tool to increase productivity in the same way that robotics has.

Read MoreIncreasing Productivity with Digitalization and AI

Job shops are implementing automation and digitalization into workflows to eliminate set up time and increase repeatability in production.

Read MoreRead Next

How Automating Gages Can Improve Inspection Processes, Increase Production

Doing so can help speed the measurement process, eliminate operator influence and generate better results.

Read More10 Ways to Think Differently about Robotic Automation

Take another look: A lot is happening in and around robotic automation. What robots might mean for machining and manufacturing is getting ready to change.

Read MoreWireless Data Collection Readies Surgical Toolmaker For Full SPC

This surgical tool manufacturer strove to ensure part quality with stringent inspections, but its manual data-entry process and hardwired measurement tools limited productivity. After purchasing a radio-based wireless data collection system, the shop witnessed a 25-percent reduction in its inspection process.

Read More