Machining Suppliers of the Future Will Be Both Bigger and Smaller

When we look for Top Shops in the years to come, what will we find? Through acquisition they’ll scale up and with technology they’ll scale down.

Share

This month we have been posting articles related to our Top Shops benchmarking program. The program by which we regularly survey machine shops to understand their capabilities and performance allows us to, among other things, identify exemplary shops in important categories each year. Read about our survey, and read about the four shops we are recognizing this year as honorees: Advanced Precision Engineering, Pacon Manufacturing, Rimeco Products and Tier One Machining and Assembly. Those profile articles all offer pictures of shops succeeding today. A complement to these profiles is our recent look back at one shop’s success over decades.

But what about the future? What will the leading shops look like that we identify in the years to come?

I have been thinking about this, both because of our annual selection of Top Shops honorees and because it’s time to look ahead. Forecasts about the future generally fail to anticipate things like, say, pandemics. As we look hopefully toward emerging from this year’s disruption, it is a good moment to see where we are and to look forward.

Here is one thing I expect to see in the future: domestic shops doing domestic work. This isn’t hard to forecast. In the years to come, North American machine shops will benefit from a reduction in outsourcing overseas. On both sides of the ocean, the increased reliance on automation means the cost savings from labor are not what they once were, while 2020 has highlighted the fragility of supply chains spanning global distances. However, some of the suppliers rising to meet the resulting opportunities will look different from the typical shop of today. Specifically, machining providers in the future will be bigger. They will also be smaller. These are coming changes that are harder to see, but ones I also expect. Here is what I mean:

First, bigger. We’ve come to a time of increased acquisition activity among machine shops — I’m seeing this. To some extent, the nature of shops will change. In the past, I could take it for granted that any standalone machining facility I visited was probably just that. An OEM might have a captive shop on its campus, but discrete and separate machining facilities have tended to be independent businesses with the owner and leaders based on-site. In the future, this will be the case less often. While I can’t gage how much acquisition of shops is happening, I believe I am seeing enough to affect the landscape.

There are various drivers of acquisition. On the buyer side, businesses already in or reliant on manufacturing see the chance to scale more quickly than organic growth would permit. Meanwhile, digital technologies (including the video meetings many of us have grown accustomed to) are making it easier to coordinate procedures, systems and even to some extent cultures across separate sites. And on the seller side, demographics — owners looking to retire — are the leading factor. In the future, we will take it for granted that a seemingly separate shop is often an outpost of a larger manufacturing organization, with sibling shops ready to support it and owners and executives based elsewhere.

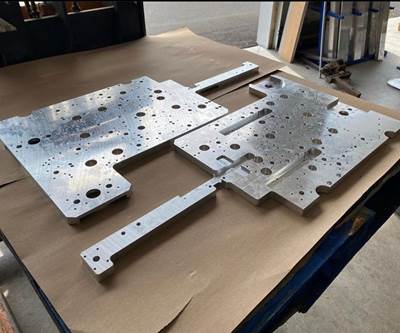

Marvel Machining, owned and run by Brad Thomas, is an example of a one-man shop.

Meanwhile, shops are also trending smaller. Another development I see is the rise of the one-person independent shop. There have always been tiny startup shops run by the owner, but in the past these shops have had to add people to grow. Today, the one-person shop (perhaps with some part-time help) can deliver greater output than in the past, and can do much more sophisticated work than such a facility could before thanks to automation such as five-axis machining and robotics, which have become much more accessible to small users. The one-person shop can stay one-person farther into its journey, and can find enough work to thrive through relationships with a relatively small number of customers nearby. In the future, an increased share of tooling, prototyping, replacement parts and short-run production will come out of these very lightly staffed businesses plugged into customers in their immediate region.

The implication of these developments is that the independent, standalone, midsize job shop — the heart of machining work for decades — will be crowded from both sides. Large machining organizations built out of multiple shops will be able to support large orders from major companies and in many cases serve them as single-source providers. Local, sophisticated, single-person or very small shops will be able to respond nimbly to companies’ small, unpredictable needs. How will the job shop as we recognize it today compete? A final development to watch in this area is that job shops won’t sit still. These are innovative businesses, and many will find new answers — specialization in particular niches perhaps — that will allow them to continue thriving.

Related Content

Job Shops Can’t Do Everything, And That’s OK

Deciding to narrow down its jobs and customers was a turning point for 2023 Top Shops Business Strategies honoree Manda Machine that has led to improvements in the front office and on the shop floor.

Read MoreCreating a Learning Culture at JD Machine

JD Machine, 2024’s Top Shops Honoree in Human Resources, embodies its “Education for Life” core value with a robust apprenticeship program and significant continuous improvement efforts.

Read MoreAutomated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read MoreRead Next

Machining a Complex Part in a One-Man Shop

Feature recognition and efficient workholding let this shop cost-effectively produce an intricate part that was bigger than the machine tool's travels.

Read More5 Hard Lessons from a 28-Year-Old Startup Machine Shop Owner

Good fortune and years of long working hours have both figured into the success of this young shop, which became its founder’s sole employment starting last year. The shop owner shares his story.

Read MoreAll Top Shops Are Winners

Standing out in one category is not enough to earn a spot among the highest-performing CNC machining businesses.

Read More